High-position air inlet pipe airtightness detection device

A technology of air tightness detection and air intake pipe, which is applied in the direction of measuring device, liquid tightness measurement using liquid/vacuum degree, fluid tightness test, etc. It can solve the problems of cumbersome detection methods and expensive detection equipment, and achieve detection Good effect and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

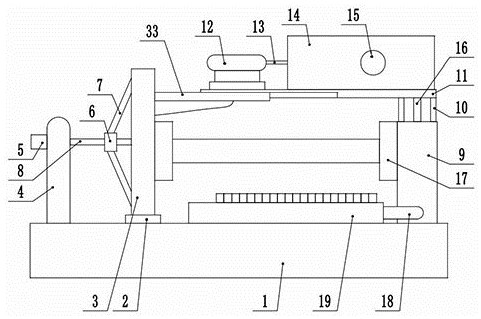

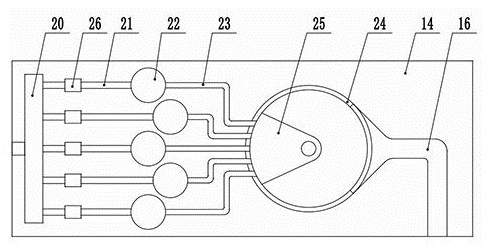

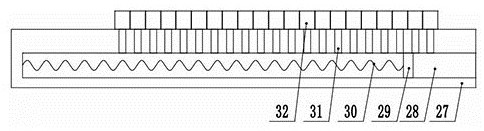

[0022] see Figure 1-4 , a high air intake pipe air tightness detection device, including a base 1, the two ends of the top of the base 1 are respectively fixedly connected to the fixed column 4 and the fixed seat 9, and the fixed column 4 is slidably connected to the sliding seat on the base 1 on the side close to the fixed seat 9 2. The top of the sliding seat 2 is fixedly connected to the moving frame 3, and the moving frame 3 is provided with a translation drive mechanism. The adjacent sides of the fixed seat 9 and the moving frame 3 are fixedly connected with a clamping seat 17, and the top of the fixed seat 9 is fixedly connected The top support frame 10, the top of the top support frame 10 is fixedly connected to the fixed top frame 11, the top of the fixed top frame 11 is fixedly connected to the partial pressure adjustment device, and one side of the partial pressure adjustment device is provided with an air compressor 12, the air compressor 12 The output end is fixed...

Embodiment 2

[0028] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, except that the translational drive mechanism includes a first drive motor 5 fixedly connected to one side of the fixed post 4, and the output shaft of the first drive motor 5 is fixedly connected to drive The rod 8 and the driving rod 8 pass through the fixed column 4 and are rotationally connected with it. The outside of the driving rod 8 is sheathed and screwed to the moving sleeve 6 , and a plurality of fixed rods 7 are fixedly connected between the moving sleeve 6 and the fixed column 4 .

[0029] One side of the moving frame 3 is fixedly connected with a moving rail 33, and the moving rail 33 is located at the side of the moving top frame and is slidably connected with it.

[0030] In the implementation process of the present invention, the high air intake pipe is first placed between the two clamping seats 17, and then the first driving motor 5 is started to drive the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com