Detection system based on PCB plug-in

A detection system and plug-in technology, used in electrical components, measuring devices, and assembling printed circuits with electrical components. Safe and convenient, avoid affecting the use, avoiding the effect of missed inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

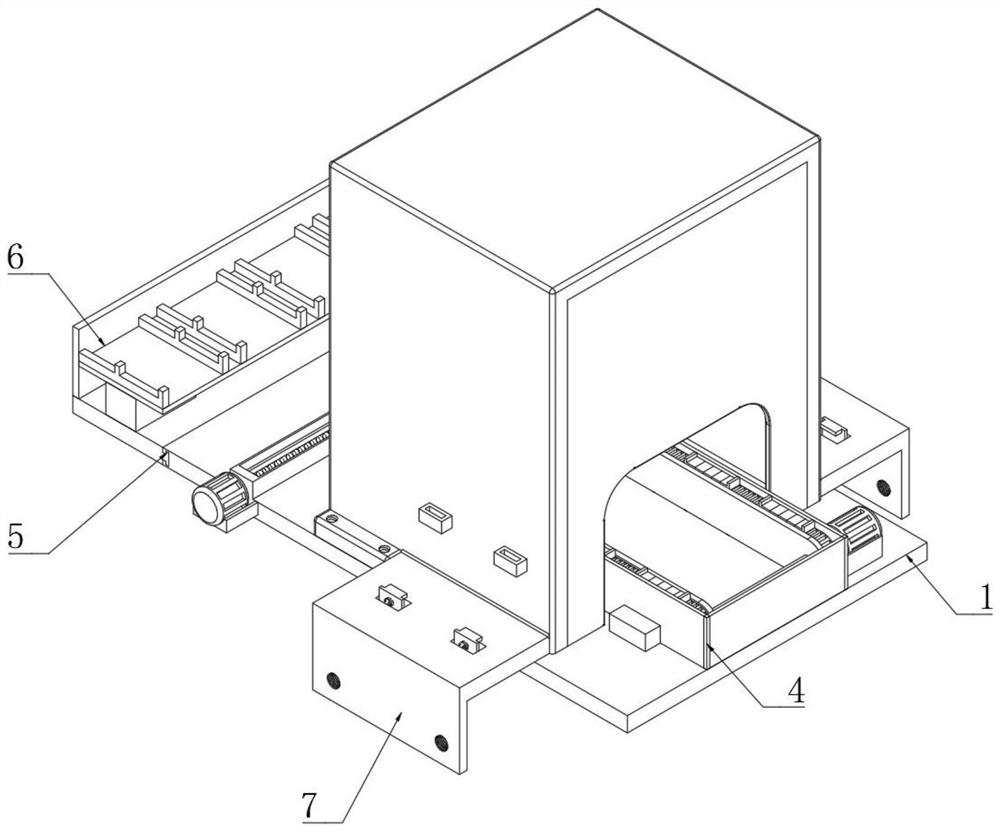

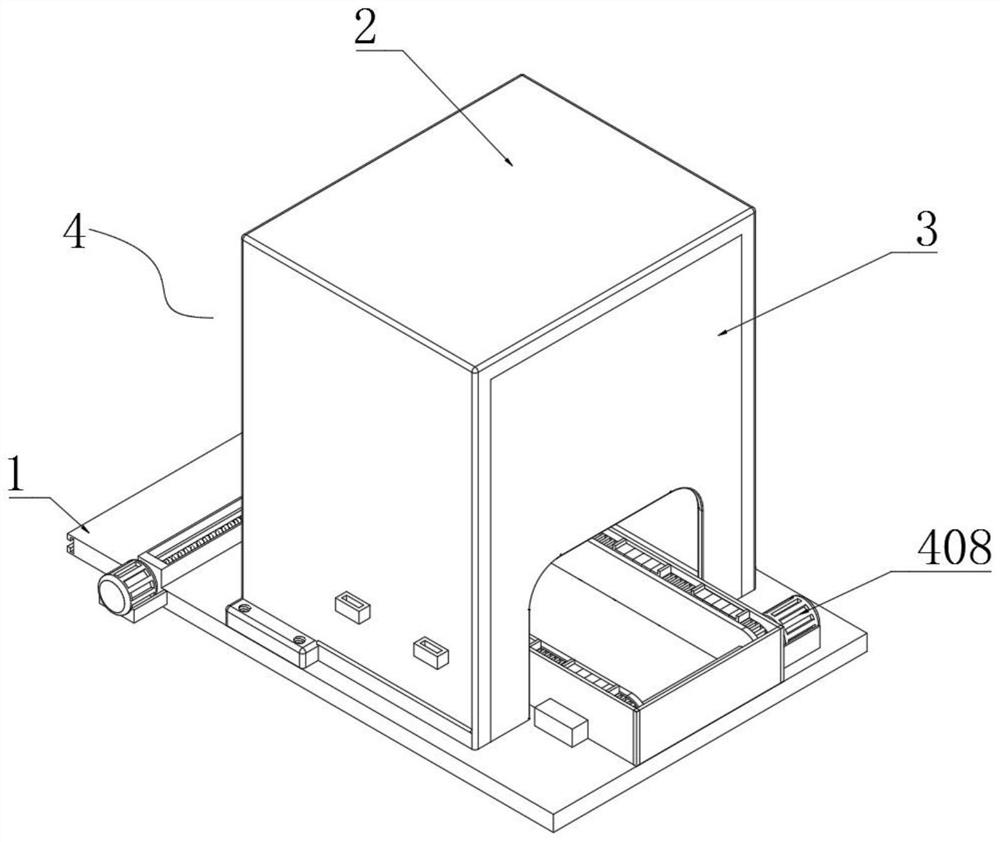

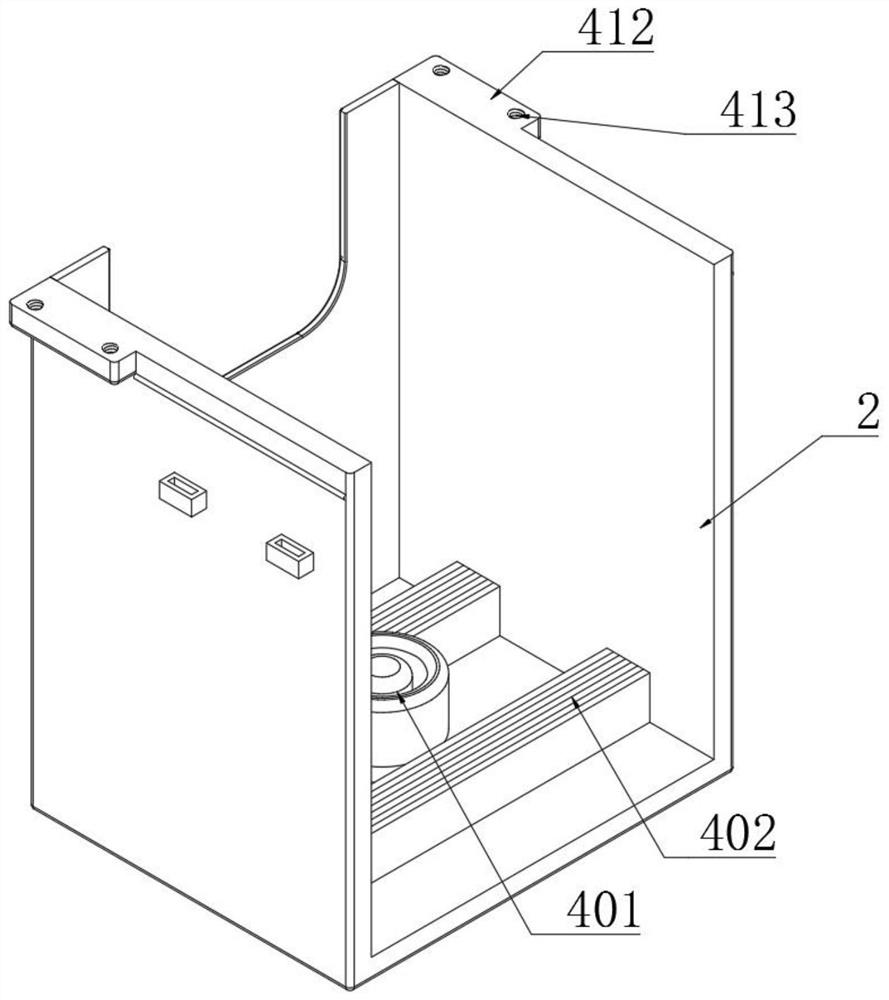

[0047] Example: such as Figure 1-9 As shown, the present invention provides a technical solution for a solder spot detection system based on a PCB plug-in. A detection system based on a PCB plug-in includes a bottom fixing plate 1, and a detection box 2 is installed in the middle of the top of the bottom fixing plate 1 through screws. 2 Both ends are symmetrically clamped and connected with a light shield 3, and a detection component 4 is installed on one side of the detection box 2. The detection component 4 includes a detection camera 401, a detection lamp 402, a fixed support plate 403, a transmission gear 404, a transmission chain 405, and a driven Gear 406, transmission rod 407, transmission motor 408, fixed protection plate 409, L-shaped support plate 410, non-slip rubber pad 411, fixed support block 412 and threaded mounting hole 413;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com