A foaming rate control method, control device, terminal equipment and storage medium

A technology of control method and control device, which is applied in the direction of program control in sequence/logic controller, water supply device, electrical program control, etc., can solve problems such as troublesome replacement of bubbler, and achieve simple operation, convenient application, The effect of high usability and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

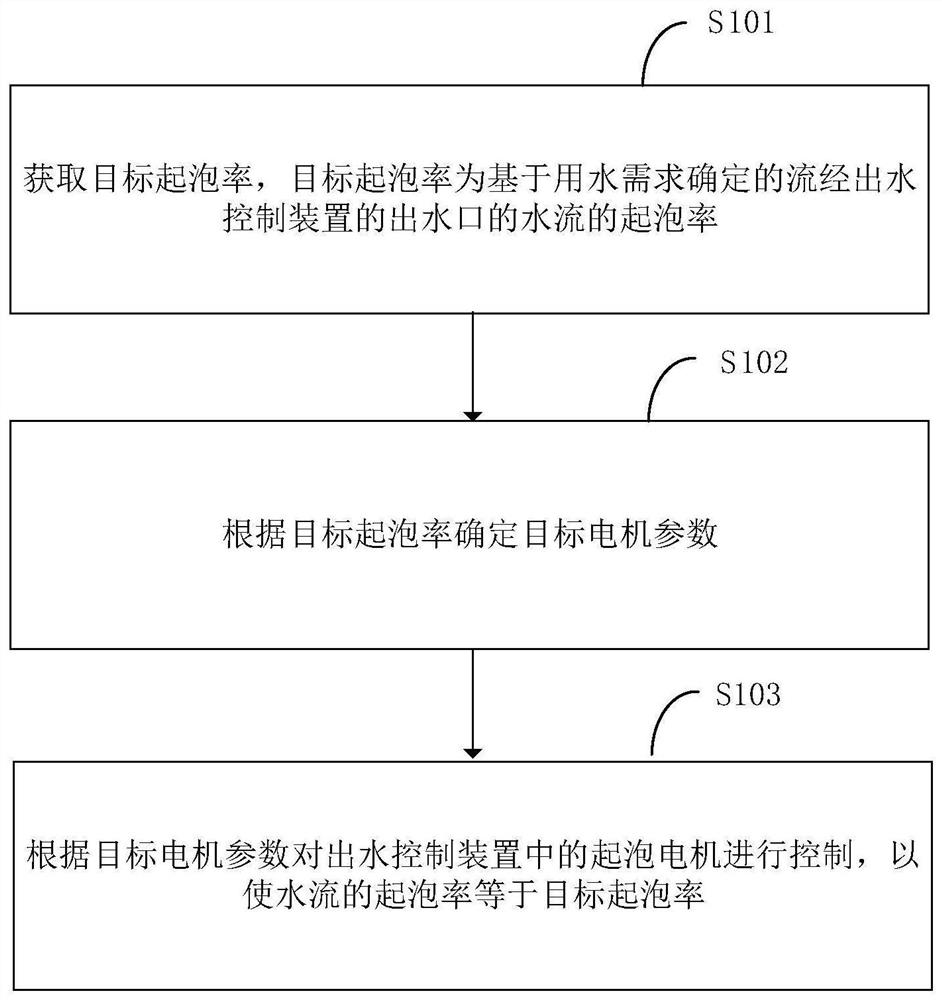

[0034] A method for controlling the foaming rate provided in Embodiment 1 of the present application is described below, please refer to the attached figure 1 , the method includes:

[0035] Step S101 , acquiring a target foaming rate, the target foaming rate is the foaming rate of the water flowing through the water outlet of the water outlet control device determined based on the water demand.

[0036] In step S101, the foaming rate refers to the ratio of the volume of air contained in the water passing through the bubbler per unit time to the volume of water passing through the bubbler per unit time. The target foaming rate is the foaming rate of the water flowing through the water outlet of the water outlet control device determined based on the water demand.

[0037] In some embodiments, obtaining the target foaming rate includes: when an electronic tag corresponding to the water demand is detected, identifying the electronic tag to obtain the target foaming rate.

[00...

Embodiment 2

[0074] image 3 An example of a foaming rate control device is shown, and for convenience of description, only parts related to the embodiment of the present application are shown. The device 300 includes:

[0075] The foaming rate acquisition module 301 is configured to acquire a target foaming rate, the target foaming rate is the foaming rate of the water flowing through the water outlet of the water outlet control device determined based on the water demand.

[0076] A determining module 302, configured to determine target motor parameters according to the target foaming rate.

[0077] The control module 303 is configured to control the foaming motor in the water outlet control device according to the target motor parameters, so that the foaming rate of the water flow is equal to the target foaming rate.

[0078] Optionally, the target motor parameters include a target speed, the foaming motor includes a first foaming motor, the first foaming motor is located in the foami...

Embodiment 3

[0094] Figure 4 It is a schematic diagram of a terminal device provided in Embodiment 3 of the present application. Such as Figure 4 As shown, the terminal device 400 in this embodiment includes: a processor 401 , a memory 402 , and a computer program 403 stored in the memory 402 and operable on the processor 401 . When the processor 401 executes the computer program 403, the steps in the above method embodiments are implemented. Alternatively, when the processor 401 executes the computer program 403, the functions of the modules / units in the above device embodiments are implemented.

[0095] Exemplarily, the above-mentioned computer program 403 may be divided into one or more modules / units, and the above-mentioned one or more modules / units are stored in the above-mentioned memory 402 and executed by the above-mentioned processor 401 to complete the present application. The above-mentioned one or more modules / units may be a series of computer program instruction segments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com