Method and system for accurately taking materials by mobile robot

A mobile robot and robotic precision technology, applied in control/adjustment systems, instruments, motor vehicles, etc., can solve problems such as low reclaiming efficiency and accuracy, inability to meet fully automatic transportation, and picking wrong materials, so as to improve efficiency and improve efficiency. Accuracy and efficiency to achieve the effect of intelligent transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

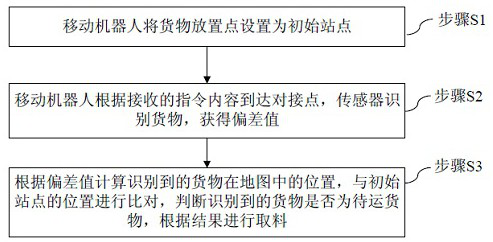

[0047] like figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a method for accurately retrieving materials by a mobile robot, including the following steps:

[0048] Step S1: The mobile robot sets the cargo placement point as the initial site;

[0049] Step S2: The mobile robot arrives at the docking point according to the received instruction content, the sensor identifies the goods, and obtains the deviation value;

[0050] Step S3: Calculate the location of the identified cargo on the map according to the deviation value, compare it with the location of the initial station, judge whether the identified cargo is the cargo to be shipped, and take the material according to the result.

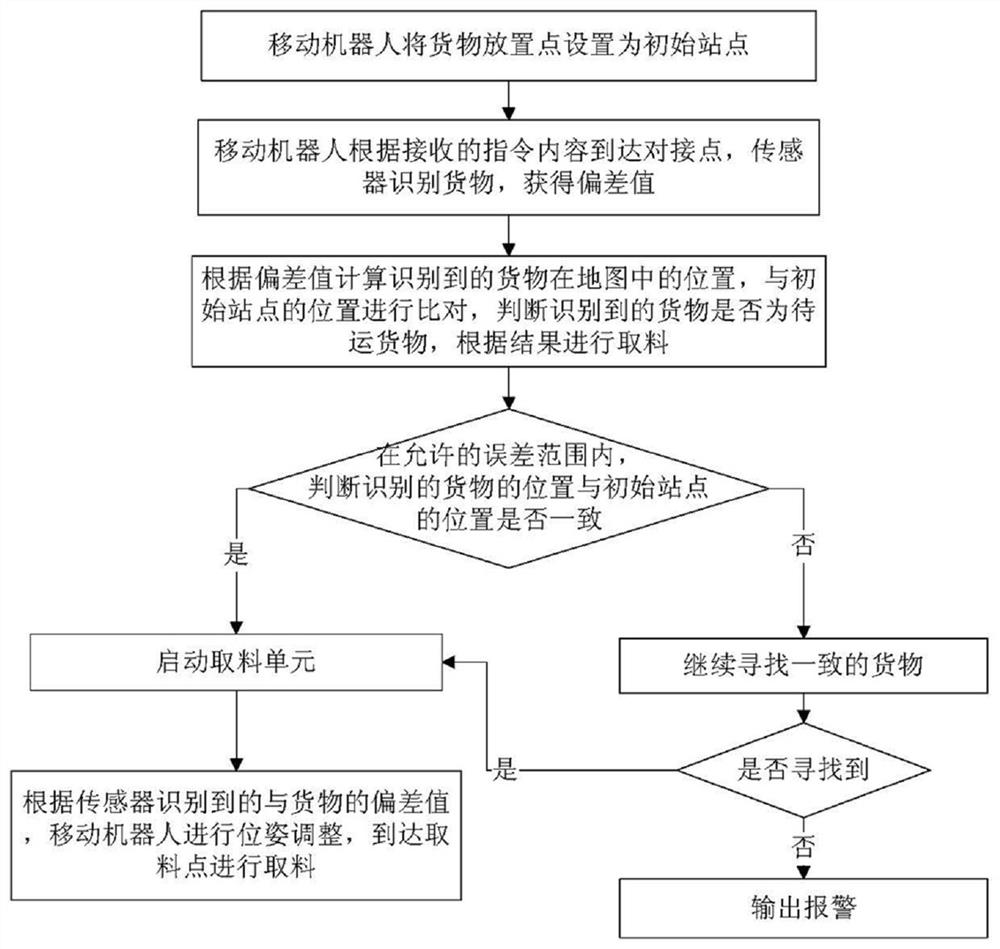

[0051] In this embodiment, the judging whether the identified goods are goods to be shipped, and taking materials according to the results further includes:

[0052] Within the allowable error range, if the position of the goods is consistent with the position of ...

Embodiment 2

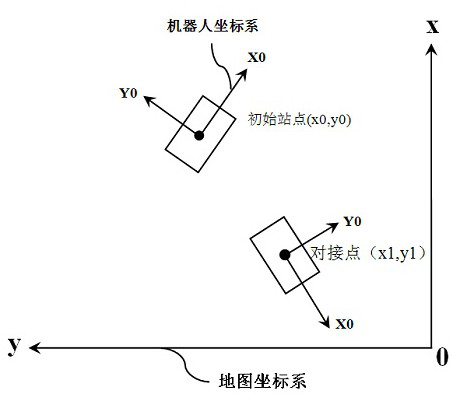

[0079] like Figure 5 As shown, Embodiment 2 of the present invention provides a system for precise material retrieving by a mobile robot, using a method for precise reclaiming by a mobile robot, including a mobile robot 1 and a sensor 2, the sensor 2 is installed on the mobile robot 1, The sensor 2 can be a sensor that can identify the distance, such as a laser radar, a camera, etc., the mobile robot 1 sets the cargo placement point as the initial site, and arrives at the docking point according to the received instruction content, and the deviation value from the cargo identified by the sensor 2 , the mobile robot 1 calculates the position of the identified cargo according to the deviation value, and compares it with the position of the initial site.

[0080] In this embodiment, the mobile robot includes a control system 11 and a motion system 12. The control system 11 includes a task management unit 111 and a navigation unit 112. The task management unit 111 sets docking po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com