Special positioning disc for lead-type electronic component reverse pasting machine

A technology of electronic components and reverse stickers, which is applied in the direction of assembling printed circuits of electrical components, electrical components, and electrical components, and can solve the problem of positioning and clamping of electronic components of different sizes, affecting the accuracy of device positioning, and no Set up dust cover and other issues to achieve the effect of improving practicability, use range, and consistent extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

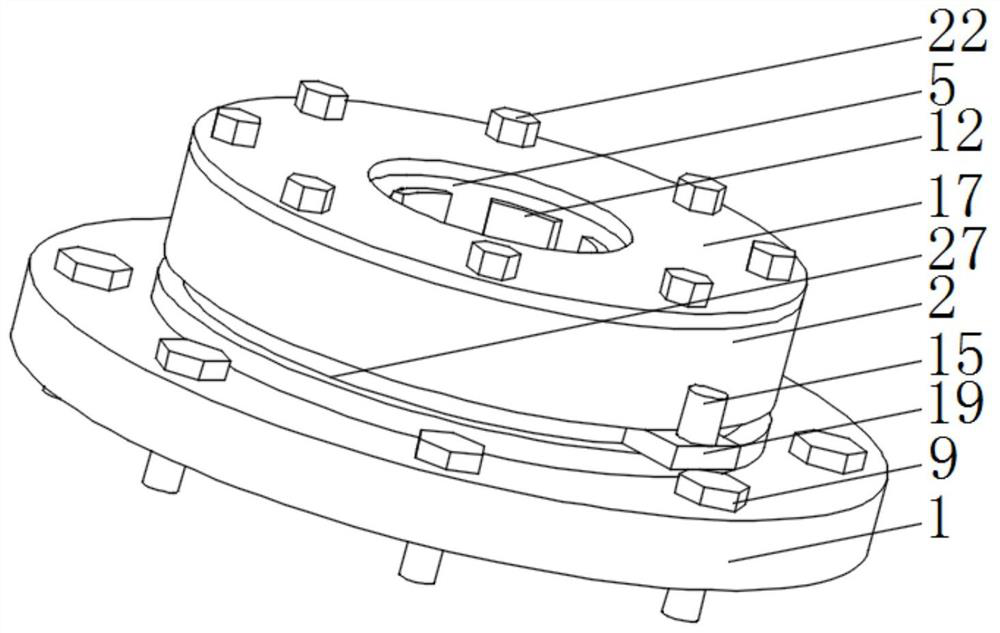

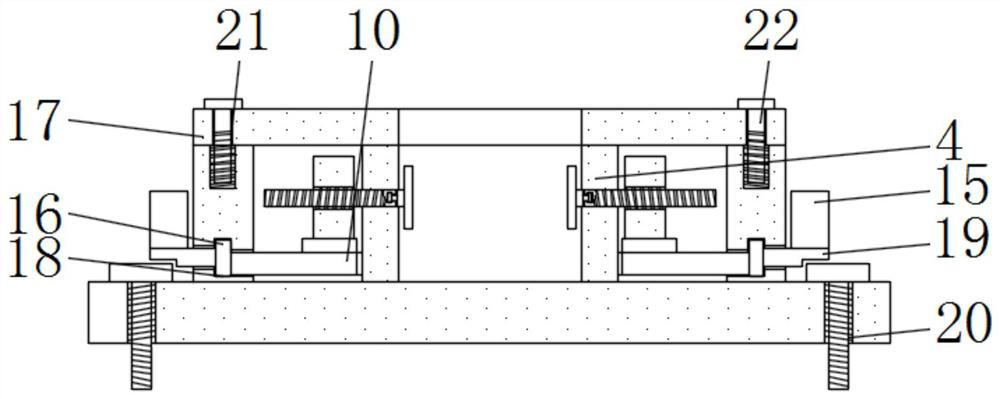

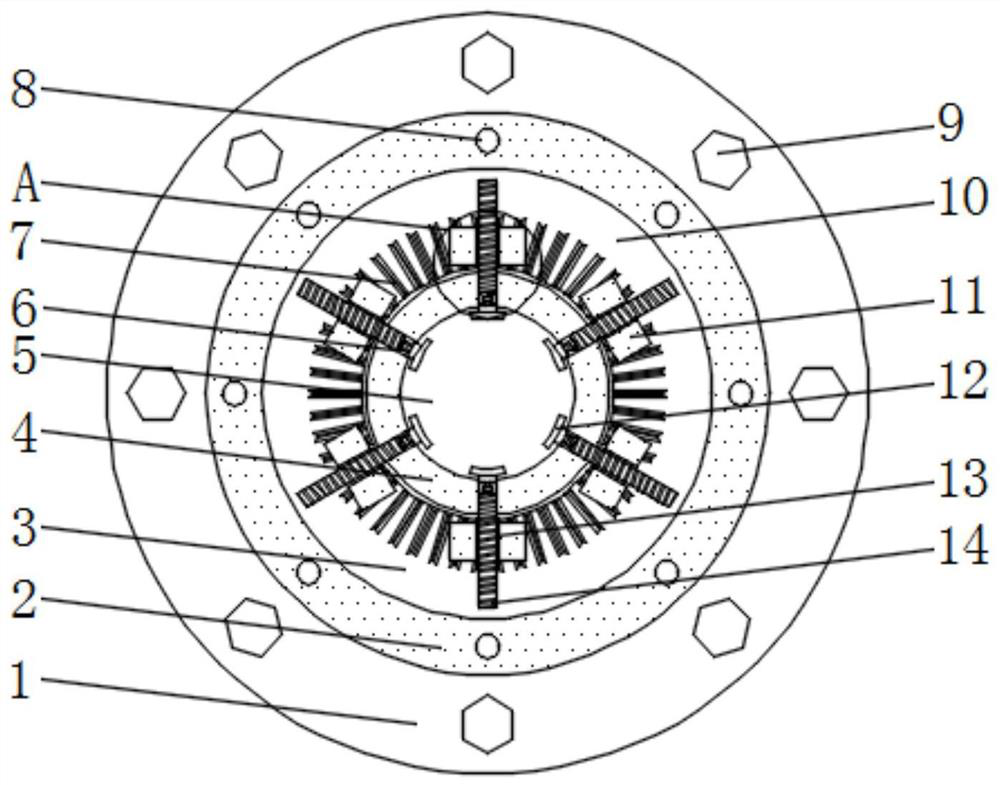

[0027] see Figure 1-4 As shown, a special positioning plate for a lead-type electronic component anti-sticking machine includes a mounting chassis 1, and first threaded holes 20 are opened around the top of the mounting chassis 1. There are eight first threaded holes 20 and eight first threaded holes. The holes 20 are evenly distributed in a ring shape, the first threaded hole 20 is threaded inside the first bolt 9, the installation chassis 1 is fixedly connected with the anti-sticking machine through the first bolt 9, and the top middle of the installation chassis 1 is fixedly connected with the fixed disk 2, The inside of the fixed plate 2 is provided with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com