Multi-connecting-rod lifting adjustable coating mechanism

A multi-link and paint technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of paint pan tilt, splash, poor stability, etc., and achieve the effect of light and simple structure, convenient maintenance and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

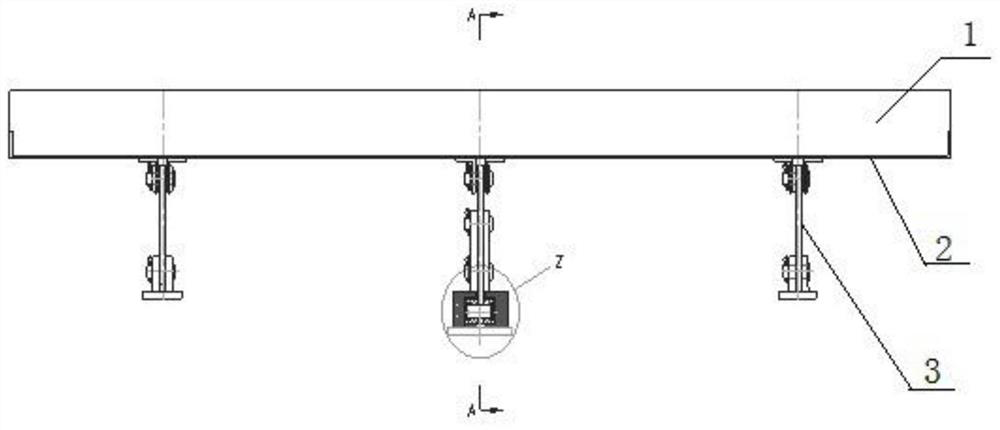

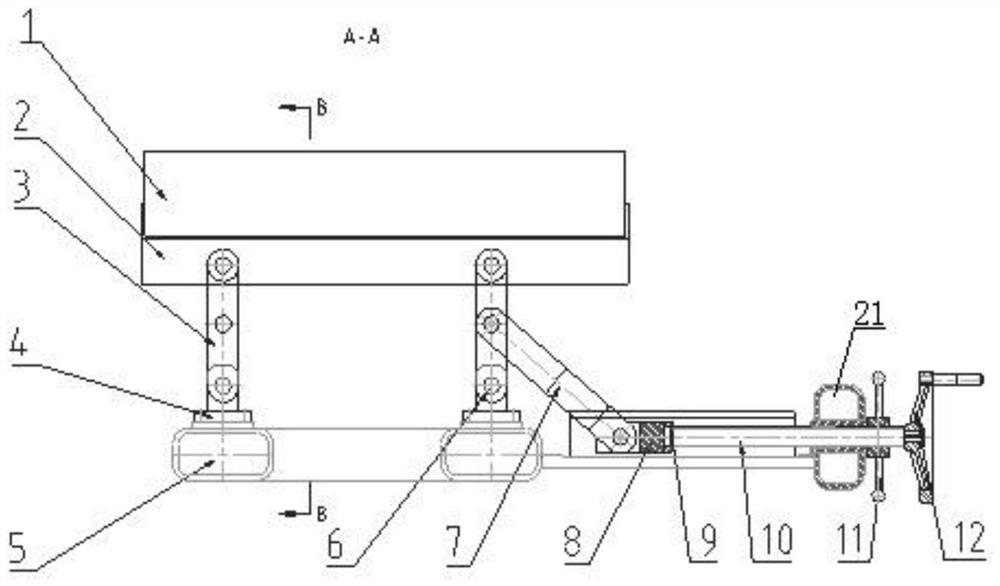

[0037] refer to figure 1 and figure 2 A multi-link lifting adjustable paint mechanism shown includes a paint tray 1, a paint tray frame 2, a lifting part, a support 4, a frame 5, a pin shaft 6, a connecting part and a drive locking part; The material tray 1, the paint tray frame 2, the lifting part, the support 4 and the frame 5 are arranged sequentially from top to bottom. It is pinned to the support 4 through a pin shaft 6; the support 4 is connected to the frame 5;

[0038] In actual use, the driving locking part is pinned to the lifting part through the connecting part to realize the lifting action of the paint tray rack and the paint tray. When the paint tray reaches the working position, it is locked and fixed by the driving locking part to fix the paint. The working position of the tray ensures the stability of the paint mechanism during the lifting process, not only avoids the paint from the paint tray from splashing out of the paint tray, but also the paint tray is...

Embodiment 2

[0041] refer to figure 1 The paint mechanism shown as a multi-link lifting adjustable is based on the first embodiment: the middle part of the paint tray 2 is a horizontal plate structure, and the surroundings of the paint tray 2 are provided with raised baffles. plate.

[0042] In actual use, the paint tray 2 adopts the technical solution, so that the paint tray 1 can be placed on it stably, ensuring that the pick-up roller can be evenly stained, thereby ensuring the quality of the product.

Embodiment 3

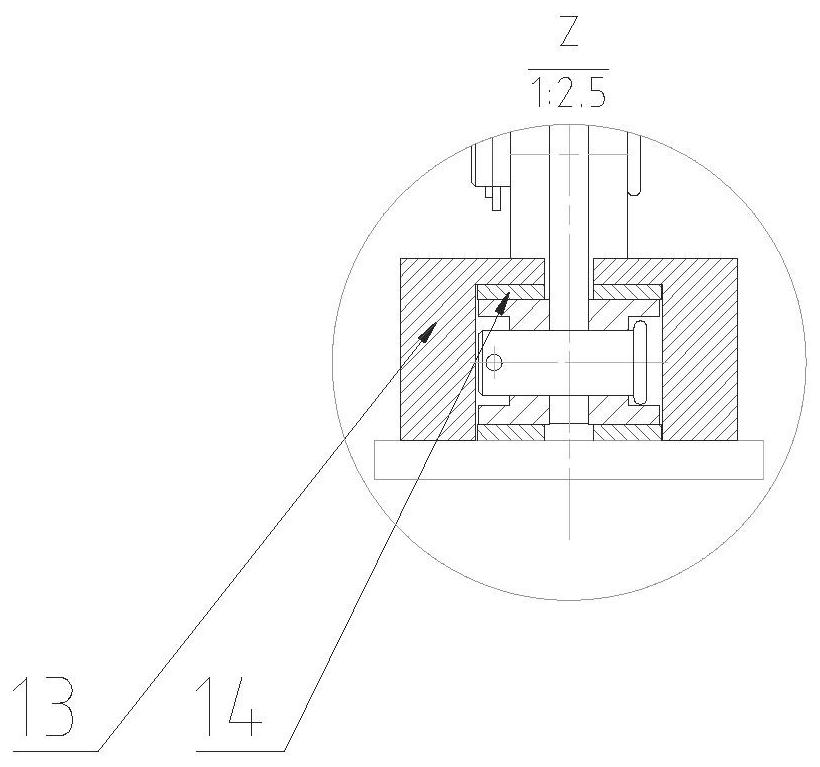

[0044] refer to figure 1 , figure 2 and Figure 4 The shown multi-link lifting and adjustable coating mechanism is based on the first embodiment: the lifting part includes the first connecting rod 3, the connecting bolt 15, the lock nut 16 and the third connecting rod 17; The first connecting rods 3 are provided with six, and the six first connecting rods 3 are divided into two rows, and each row is provided with three and evenly arranged; the upper, middle and lower parts of the six first connecting rods 3 are provided with connecting through holes; A connecting rod 3 is pinned to the paint tray 2 through the upper through hole, and the first connecting rod 3 is pinned to the support 4 through the lower through hole; the third connecting rod 17 passes through three first connecting rods in one row. The middle part of the rod 3 has a through hole, and the two ends of the third connecting rod 17 are respectively connected with the first connecting rod 3 on both sides through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com