Anti-splashing injection molding device for PVC plastic production

An anti-splash and injection molding technology, which is applied in the field of anti-splash injection molding devices, can solve problems such as splashing, mold adhesion, and affecting normal work, and achieve the effects of preventing damage, uniform force, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

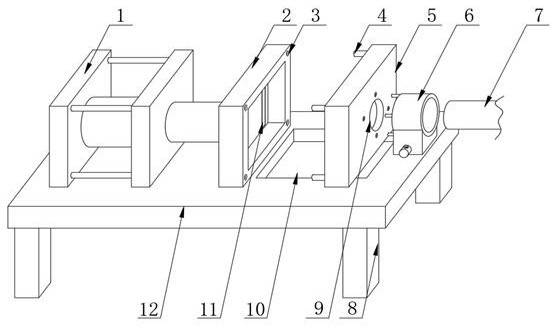

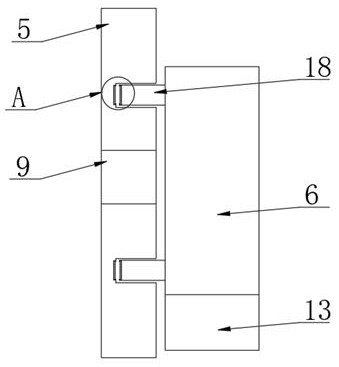

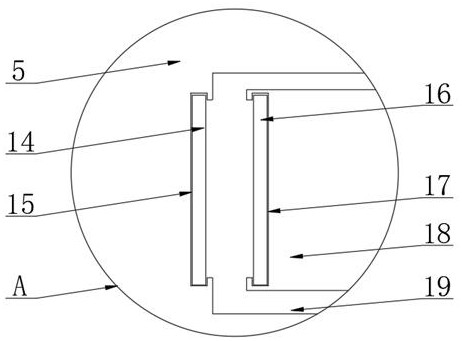

[0021] see Figure 1~5 , in an embodiment of the present invention, a splash-proof injection molding device for PVC plastic production, including a workbench 12, the bottom of the workbench 12 is integrally installed with a base 8, and the upper surface of the workbench 12 is fixedly installed with a cylinder 1 The telescopic end of the cylinder 1 is connected with a moving module 2, and one side of the moving module 2 is provided with a positioning groove 3, and the inside of the moving module 2 is provided with a top plate 11, and one side of the moving module 2 is fixedly connected with a fixing seat 26, and the fixing seat One side middle position of 26 is provided with electric telescopic rod 25, and the telescoping end of electric telescopic rod 25 is connected with connecting plate 28, and one side of connecting plate 28 is provided with connecting post 27, and one end of connecting post 27 is affixed with top plate 11, One side of the electric telescopic rod 25 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com