Auxiliary device for vacuum forming based on connection of composite material and metal framework

A metal frame and auxiliary device technology, which is applied in the field of fiber composite shell and metal frame connection, can solve the problems that the vacuum-assisted forming process cannot be used, achieve the effect of small glue content ratio, stable quality, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The auxiliary device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

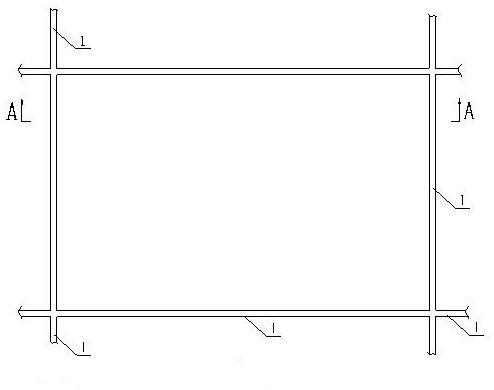

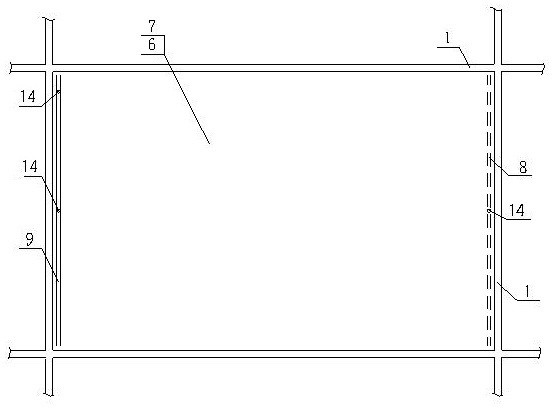

[0038] see figure 1 , figure 2 and image 3 , shows a metal frame 1 with a dovetail joint 2, which can be composed of one or more grids, and the welding seams on their mutual end surfaces (exposing the outside of the vacuum film coating) must meet the requirements of vacuum degree; the metal The surface of the frame 1 should be smooth, bright and free of impurities, so as to ensure that the tightness of the place where it is pasted with the vacuum film 11 meets the requirements of the vacuum degree;

[0039] Figure 4 and Figure 5 Shown is to make grid blocks 3 with a certain interval of several wooden strips 4, and its length and width dimensions are slightly smaller than the corresponding metal frame grid, and the thickness dimension is then formed in the grid. Deformation is appropriate.

[0040] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com