Brake device and wheel assembly

A braking device and axle technology, applied in the direction of motor vehicles, bicycle accessories, bicycle brakes, etc., can solve the problem of easy damage to the actuating rod and guide sleeve, complicated installation process, and high pressure between the locking piece and the actuating rod and guide sleeve, etc. problem, to achieve the effect of easy assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, but are not intended to exhaust all possible ways of the present invention, nor are they intended to limit the scope of the present invention.

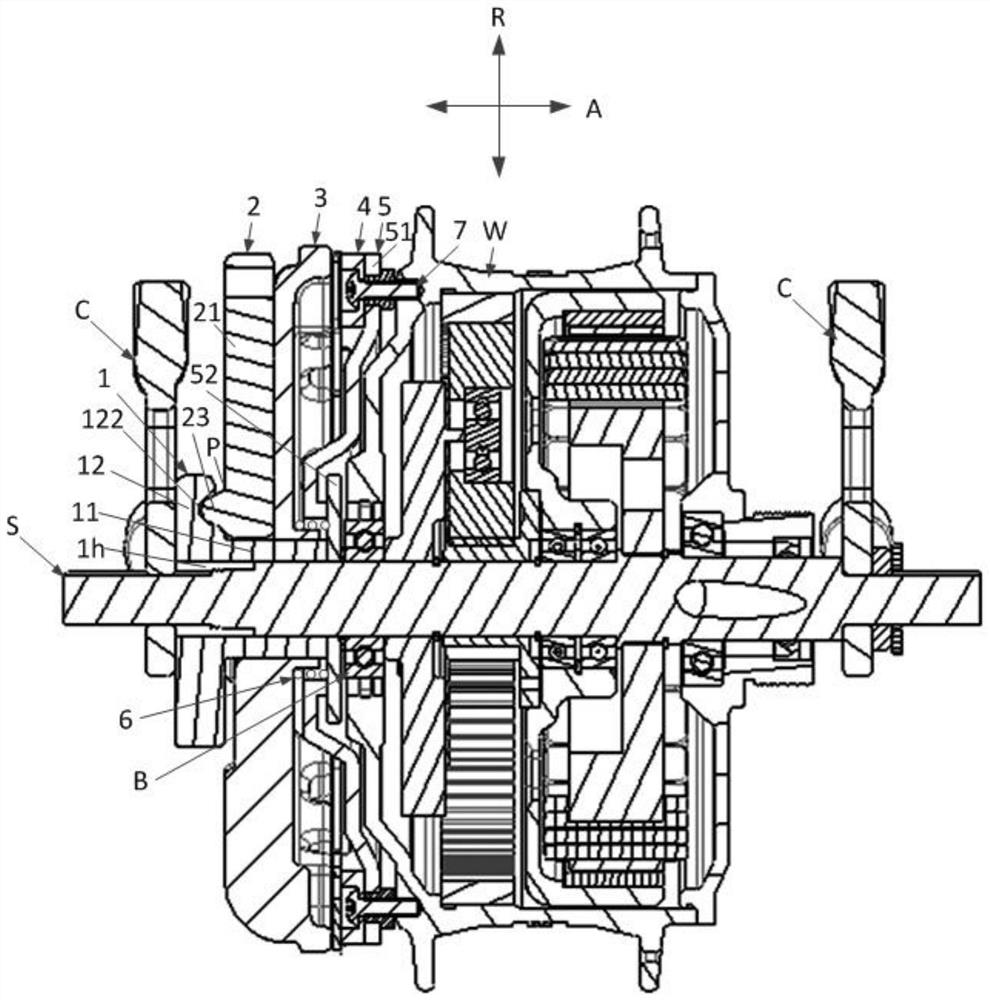

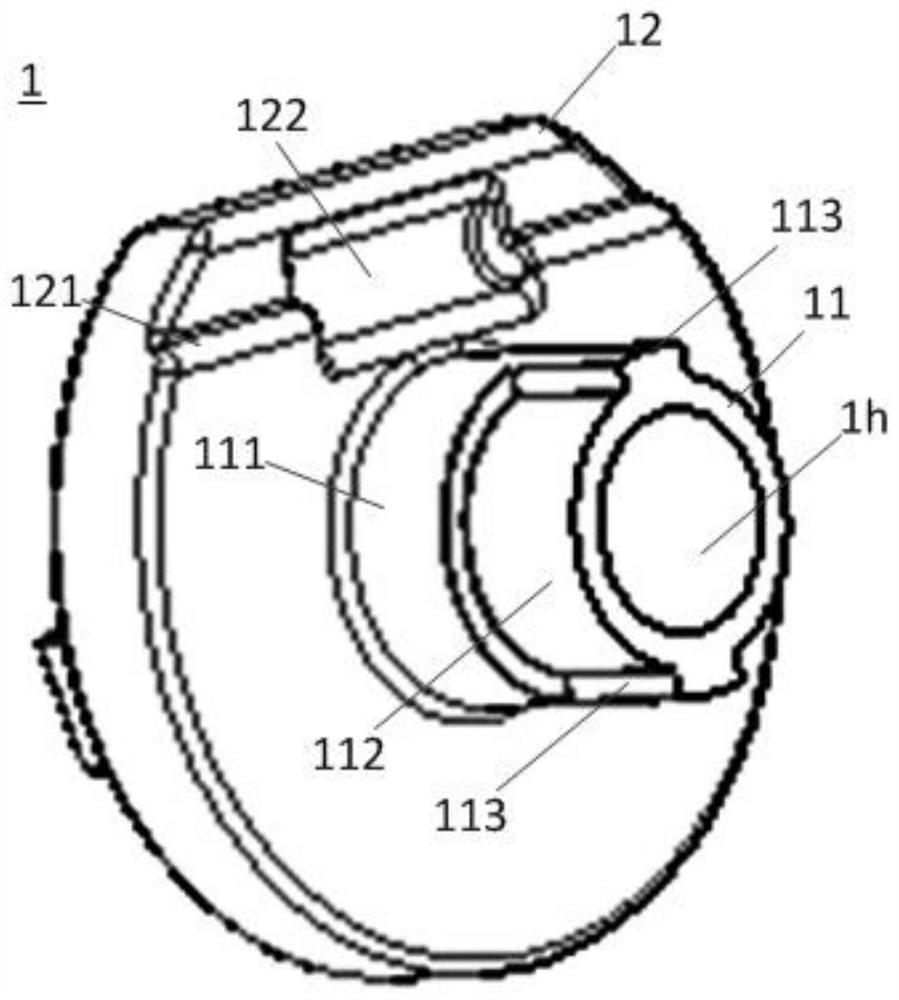

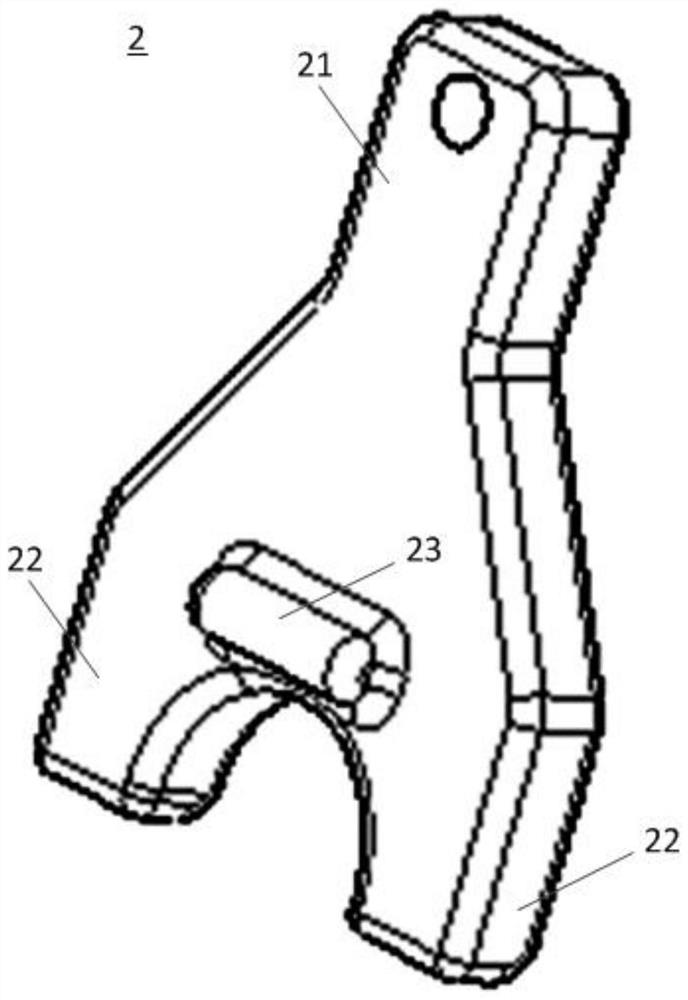

[0030] The specific structure of the wheel assembly including the brake device according to the present invention will be described below with reference to the drawings. In the drawings, unless otherwise specified, the axial, radial and circumferential directions refer to the axial, radial and circumferential directions of the axle of the wheel assembly respectively; one side of the axial direction refers to figure 1 The left side of the axis, the other side of the axis refers to figure 1 on the right side of the . In addition, "torque-proof" connection between two parts me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap