Cone pump for chemical fiber production and with dust setting and pressure tapping device

A warehouse pump and chemical fiber technology, which is applied in the field of chemical fiber production warehouse pumps, can solve the problems of aging wear and damage, high valve action frequency, dust filter and check valve damage, etc., and achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

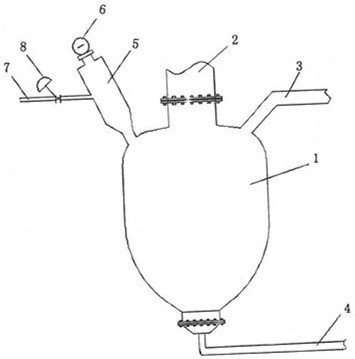

[0009] figure 1 As shown: the warehouse pump with pressure is provided with a dust collector 5 connected to the inside on the side of the feed port 2 above the pump body 1, and an air intake pipe A4 leading to the interior is provided at the bottom, and the feed port 2 above the pump body 1 is on the other hand A discharge nozzle 3 is provided on one side, and a pressure transmitter 6 is installed on the top of the dust suppressor 5. One side of the dust suppressor 5 is connected with an air inlet pipe B7 communicating with the inside, and an angle seat valve 8 is installed on the air inlet pipe B7.

[0010] The pressure transmitter 6 at the top of the present invention can collect and transmit the pressure of the warehouse pump 1 in real time. During the fluidization stage, the angle seat valve 8 is opened. During operation, a small amount of compressed air enters the dust suppressor 5 through the intake pipe B7, and in the dust suppressor 5 An air seal is formed inside to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com