Heading machine excavation cabin pressure measuring system and application method thereof

The technology of a measurement system and application method, which is applied in the field of water and soil pressure measurement, can solve problems such as the inability to accurately measure the soil pressure in the excavation cabin, and achieve the effect of avoiding gushing and working safely and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

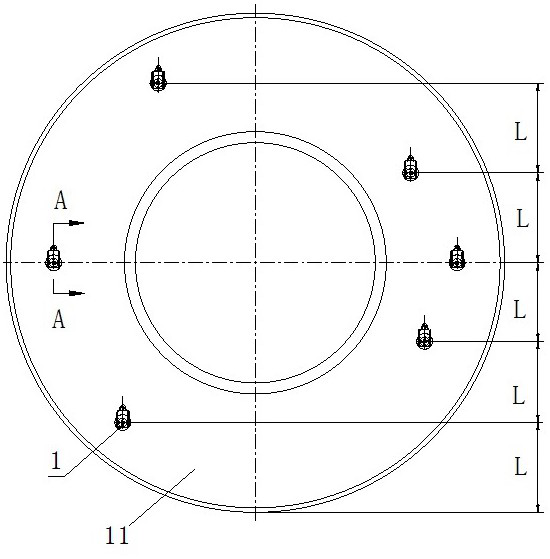

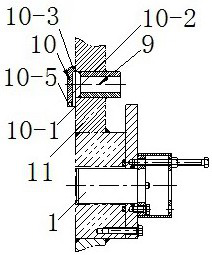

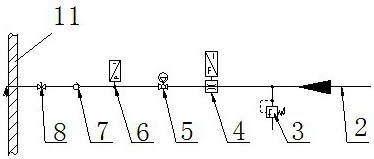

[0043] Embodiment 1, a kind of roadheader excavation chamber pressure measurement system, such as figure 1 and 2 As shown, it includes an earth pressure sensor 1 arranged in the excavation cabin, the earth pressure sensor 1 is equipped with a flushing system, and the nozzle 9 of the flushing system leads to the detection surface of the earth pressure sensor 1 . By controlling the scouring system, the detection surface of the earth pressure sensor 1 can be cleaned quantitatively or indefinitely at regular intervals or in real time, so as to avoid the problem of inaccurate pressure monitoring readings caused by dregs wrapping the detection surface of the earth pressure sensor 1 .

[0044] Specifically, the spray head 9 leads to the detection surface of the earth pressure sensor 1 along the side wall of the earth pressure sensor 1 , and the washing medium passing through the spray head 9 will wash the detection surface of the earth pressure sensor 1 . or, as in figure 2 As sho...

Embodiment 2

[0047] Embodiment 2, a kind of excavation cabin pressure measurement system of roadheader, such as figure 2 , 4 , 5, the inner side of the guide plate 10 is provided with a groove 10-2, the space surrounded by the groove 10-2 is used for the circulation of the flushing medium, and the groove wall 10-3 of the groove 10-2 is U The two side walls are inclined outwards, and the opening between the two side walls is the guide port 10-1 close to the earth pressure sensor 1. The inclined U-shaped structure enables the flushing medium flowing out from the nozzle 9 to expand along the front end of the front shield partition 11, and can flush the muck in a wide range of the detection surface of the earth pressure sensor 1, further ensuring the flushing effect.

[0048] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0049] Embodiment 3, a pressure measurement system for an excavation chamber of a roadheader, the guide plate 10 includes a baffle 10-4 corresponding to the contour of the groove wall 10-3, that is, the baffle 10-4 is approximately fan-shaped as a whole, and one end of the baffle is Arc-shaped, the orthographic projection of the side of the baffle plate 10-4 close to the earth pressure sensor 1 is a concave arc-shaped edge 10-5, and the inner side of the arc-shaped edge 10-5 is provided with chamfers. The edge of the guide plate 10 is set in an arc shape, so as to facilitate the relative movement of the muck and prevent it from bearing the larger shearing force of the muck. The outer surface of the baffle plate 10-4 is provided with a wear-resistant layer to prevent the dregs in the excavation cabin from wearing the baffle plate 10-4.

[0050] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com