Expansion and contraction rate testing device and method for flat belt and high-place operation safety belt

A technology of testing device and testing method, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., can solve the problem of insufficient awareness of shrinkage performance, and achieve reliable testing method, convenient use, Accurately Measured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

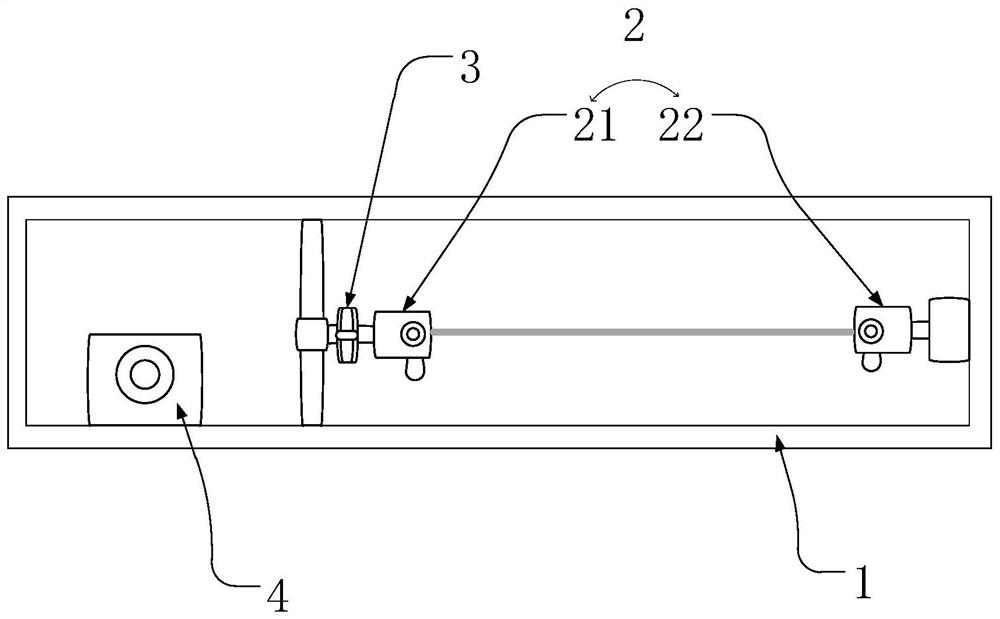

[0079] figure 1 It is a schematic diagram of the test device for stretching rate of the flat belt and safety belt for working at heights disclosed in Embodiment 1.

[0080] In Embodiment 1, the test device for the expansion rate of the flat belt and safety belt for working at heights includes:

[0081] The device support frame body 1, the device support frame body 1 includes an upper surface frame and a lower surface frame opposite up and down, and a left surface frame and a right surface frame opposite left and right;

[0082] The clamping assembly 2 includes a first clamping part 21 and a second clamping part 22, wherein the second clamping part 22 is set and installed on the right surface frame, and the first clamping part 21 is set and connected to the upper surface frame and the On the movable part on the lower surface frame, the movable part can move left and right in the horizontal direction to realize the distance adjustment between the first clamping part 21 and the ...

Embodiment 2

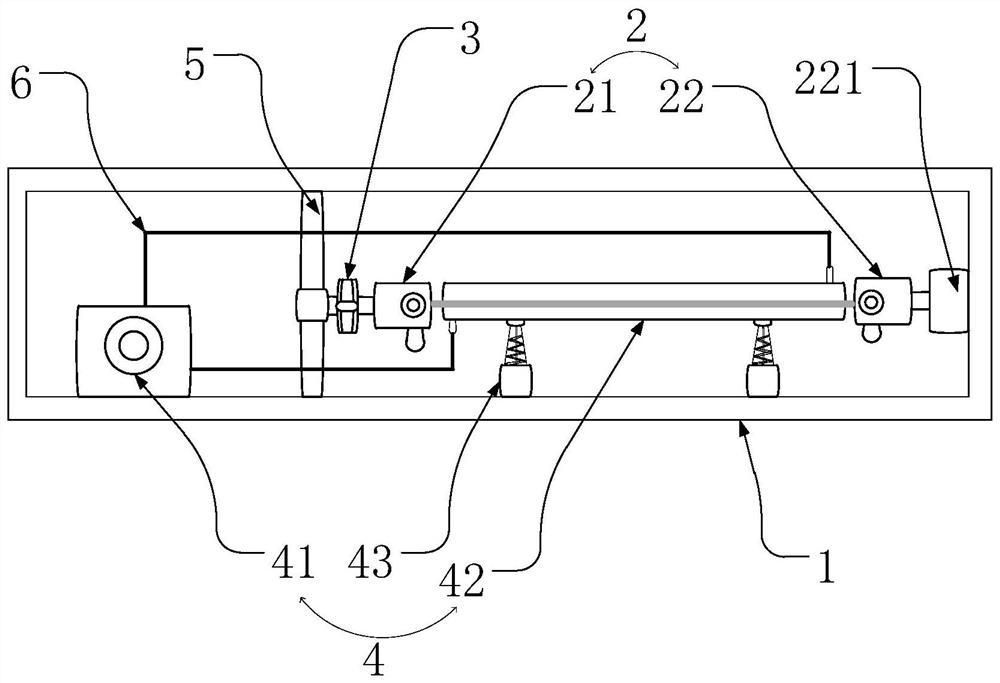

[0086] figure 2 It is a schematic diagram of the test device for stretching rate of flat belt and safety belt for working at heights disclosed in embodiment 2.

[0087] In embodiment 2, flat belt, safety belt stretch rate test device for working at heights includes:

[0088] The device support frame body 1, the device support frame body 1 includes an upper surface frame and a lower surface frame opposite up and down, and a left surface frame and a right surface frame opposite left and right;

[0089] The clamping assembly 2 includes a first clamping part 21 and a second clamping part 22, wherein the second clamping part 22 is installed on the right surface frame, and the second clamping part fixing part 221 provided on the right surface frame Fixedly connected, the first clamping part 21 is set and connected on the stretching rod 5, and the two ends of the stretching rod 5 are movably connected with the upper surface frame and the lower surface frame respectively, so as to b...

Embodiment 3

[0093] Tensile rate test of flat belt and safety belt for working at heights

[0094] Use the stretch rate test device of the flat belt and high-altitude operation safety belt to test the expansion ratio of the flat belt and high-altitude operation safety belt, which can be carried out according to the following methods:

[0095] (1) The two ends of the sample to be tested are respectively fixedly connected to the first clamping part and the second clamping part; usually, the sample to be tested can be pretreated so that the sample to be tested can obtain a set initial measurement state; for example, it can be Place the sling or high-altitude safety belt in the air with a relative humidity of less than 10% for more than 24 hours, then place it in an environment with a temperature of 20°C and a relative humidity of 65% for more than 72 hours, and then cut a certain length of test sample. For example 4000mm;

[0096] (2) Adjust the distance between the first clamping part and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com