Fluid filter with secondary filter element of lightweight construction

A fluid filter, secondary filter technology, applied in membrane filters, dispersed particle filtration, gas treatment, etc., that can address limiting seal abutment, secondary filter element and filter housing manufacturing tolerances, filter media Easy to damage and other problems, to achieve the effect of easy and safe installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

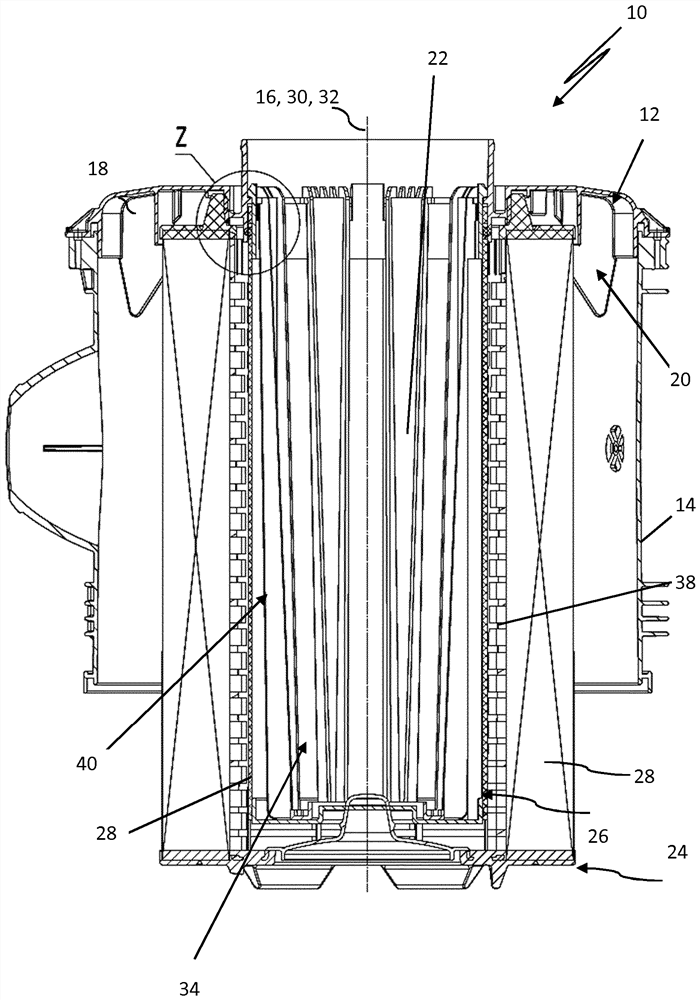

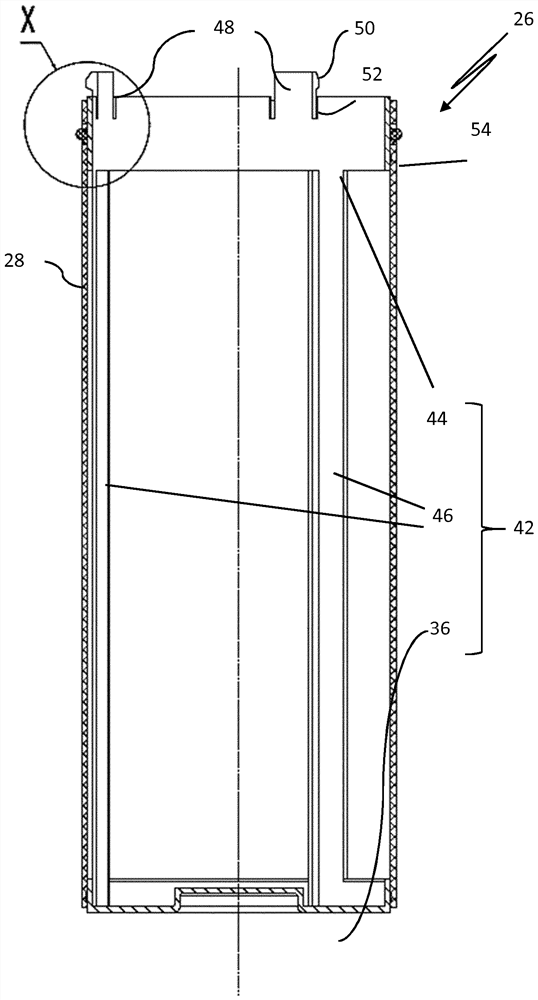

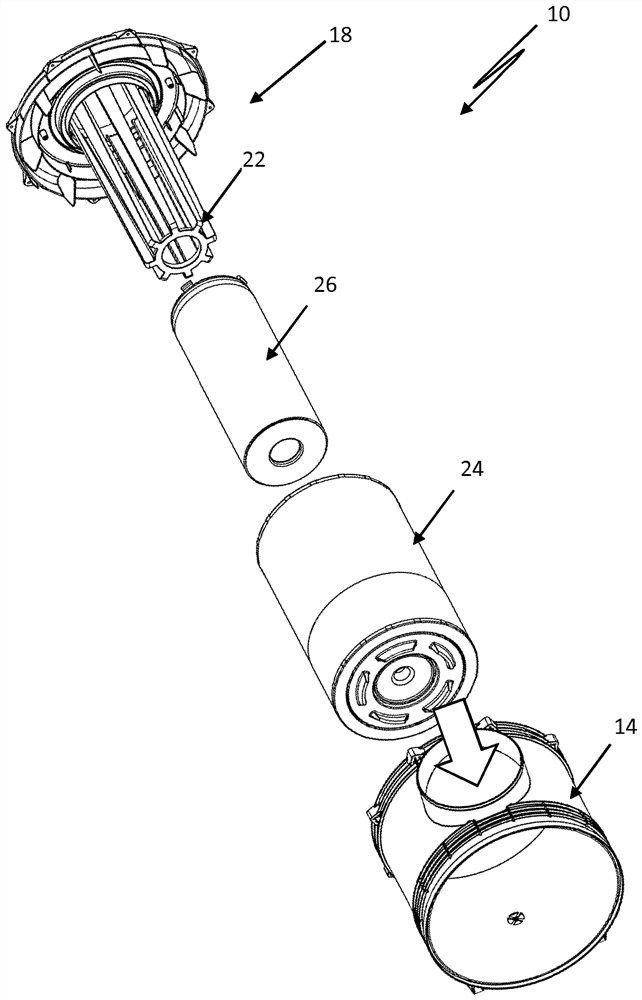

[0028]referenceFigure 1 to Figure 3 , A fluid filter 10 according to the present invention is shown, and the fluid filter 10 can be used, for example, as an air filter for an air inlet of a combustion engine (specifically, a utility vehicle such as a truck or a bulldozer). infigure 1 , The fluid filter 10 is shown in its partially assembled state, andfigure 2 withimage 3 An exploded view of the fluid filter 10 is shown. The fluid filter 10 includes a multi-part filter housing 12 having a filter container 14 extending along the longitudinal axis 16 of the filter housing 12, the filter container 14 being only partially shown infigure 1 in. There is a housing cover 18 provided at one end of the filter container 14 for closing the opening 20 of the filter container 14. The housing cover 18 is detachably locked and fixed to prevent loosening on the filter container 14, which can be achieved, for example, by a snap fit of the housing cover 18 and the filter container 14, threaded engageme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com