A construction pipeline welding mechanism

A welding mechanism and building construction technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficulty in mass operation and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

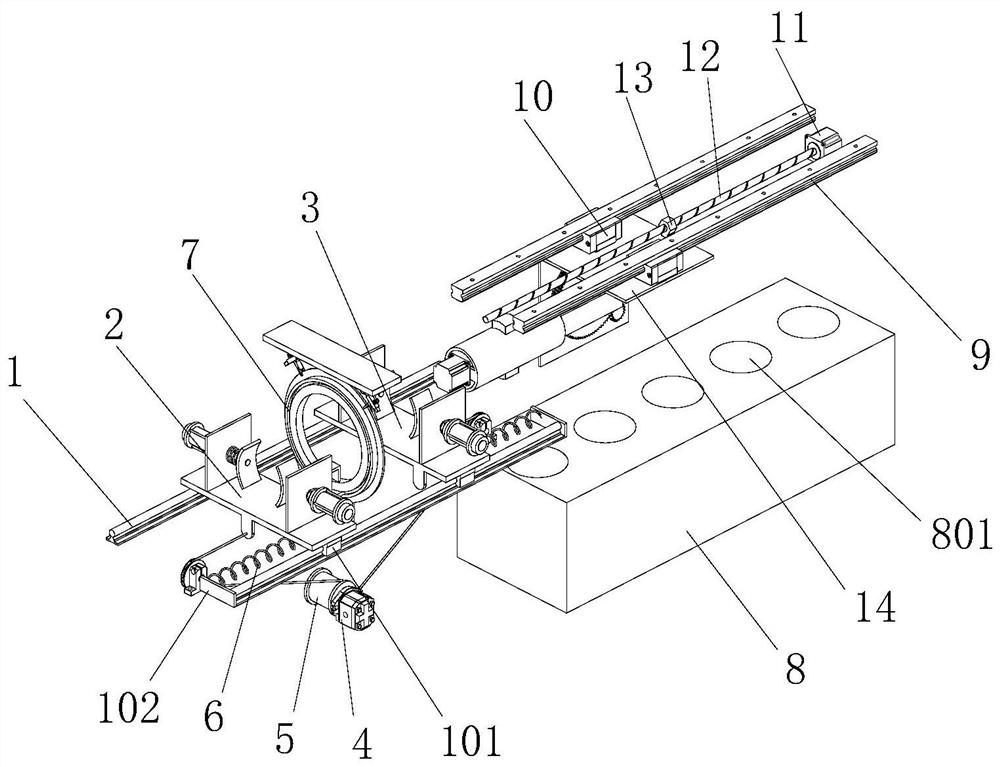

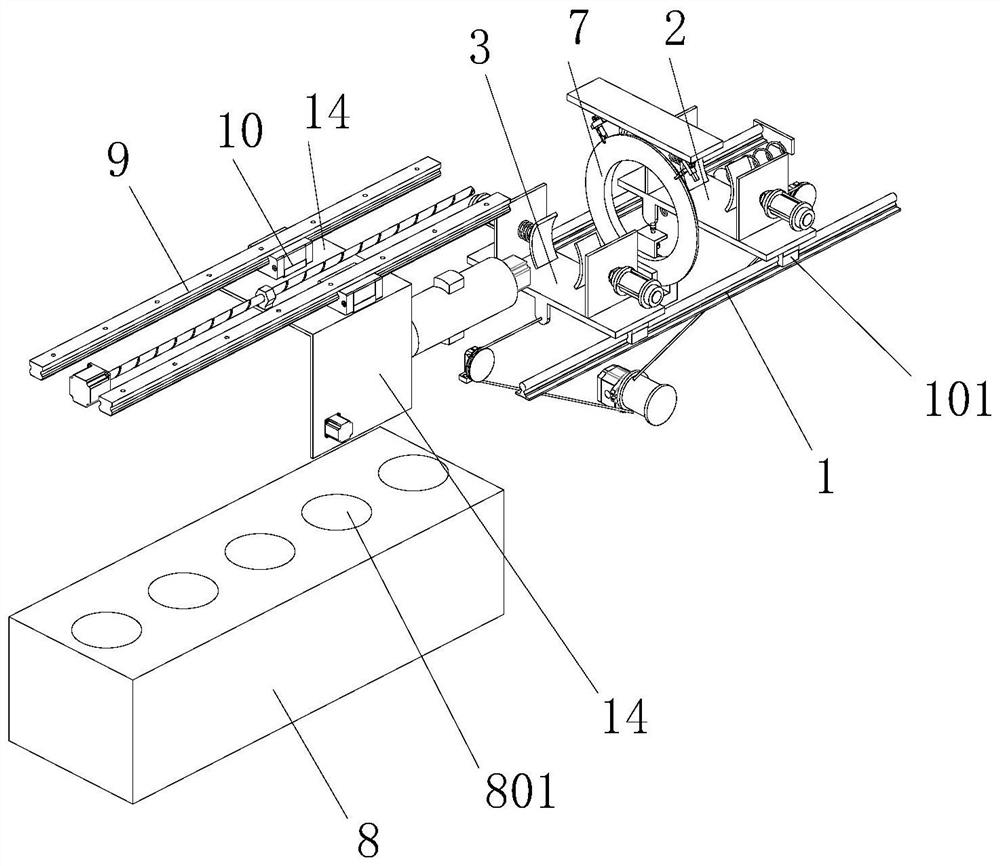

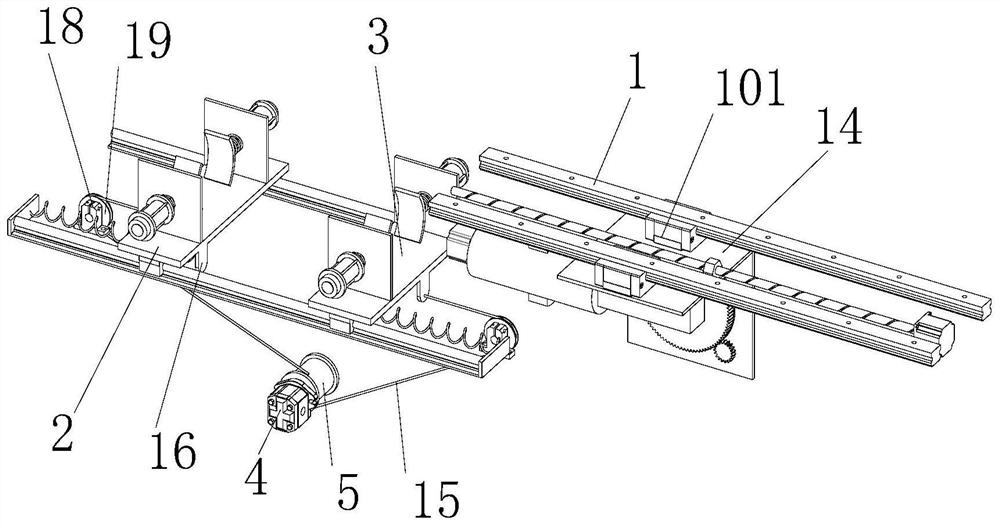

[0025] refer to Figures 1 to 7 A kind of building construction pipeline welding mechanism shown, comprises fixed guide rail 1, and described fixed guide rail 1 is provided with two, and fixed guide rail 1 is fixedly installed, and each fixed guide rail 1 is all equipped with two sliders 101, two The two corresponding sliders 101 on the fixed guide rail 1 are fixedly installed with the first bearing platform 2, and the other two corresponding sliders 101 on the two fixed guide rails 1 are fixedly installed with the second bearing platform 3. One side of the platform 2 and the second bearing platform 3 is provided with a traction flange 17, and the other side of the first bearing platform 2 and the second bearing platform 3 is equipped with an elastic flange 16, and the two sides of one of the fixed guide rails 1 Each end is fixedly installed with an extension piece 102, and each extension piece 102 is connected with the corresponding elastic flange 16 by a tension spring 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com