Tensile flame-retardant plastic woven bag

A flame-retardant plastic and woven bag technology, which is applied in the field of woven bags, can solve the problems of time-consuming and laborious, easy to be punctured, and affect the service life of woven bags, and achieve the effects of enhancing work strength, improving convenience, and preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

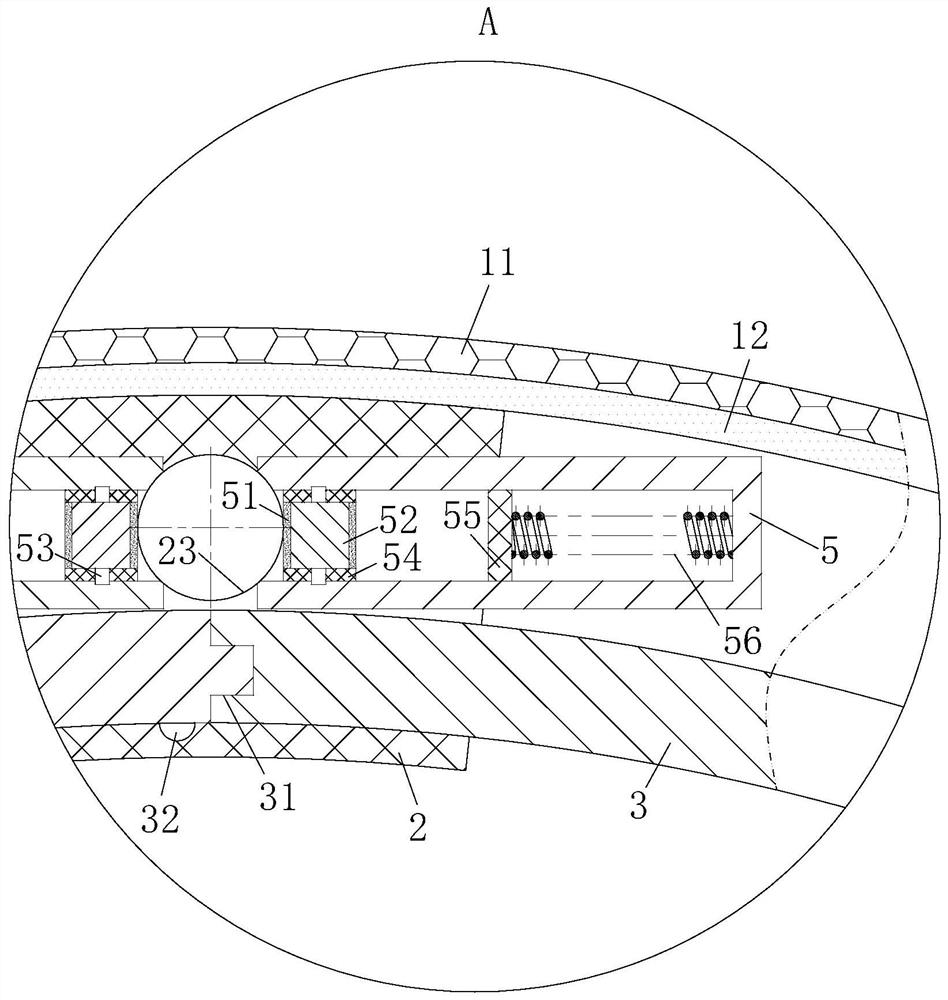

[0034] As an embodiment of the present invention, a piston 55 is slidably connected to the middle part of the lubricating chamber 5, and the piston 55 is connected to the end of the lubricating chamber 5 through a spring 56; Fully and effectively utilized, at this time, when the lubricating chamber 5 outside the piston 55 is filled with lubricating oil, the piston 55 reaches a balance under the gravity of the lubricating oil and the rebounding force of the spring 56, when the lubricating oil gradually decreases after use At this time, the rebound force of the spring 56 is greater than the gravity of the lubricating oil, so that the piston 55 pushes the lubricating oil to the position where it fits the lubricating layer 51 under the action of the spring 56, so that the lubricating oil inside the lubricating chamber 5 is obtained. Full and effective use.

[0035] As an embodiment of the present invention, the two slots 21 on the support bar 2 communicate with each other, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com