Foamed concrete insulation board

A technology of foamed concrete and insulation boards, applied in insulation, building components, construction, etc., can solve problems such as low connection strength and high safety risks, so as to improve safety, avoid loosening of anchor rods, and reduce the probability of falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

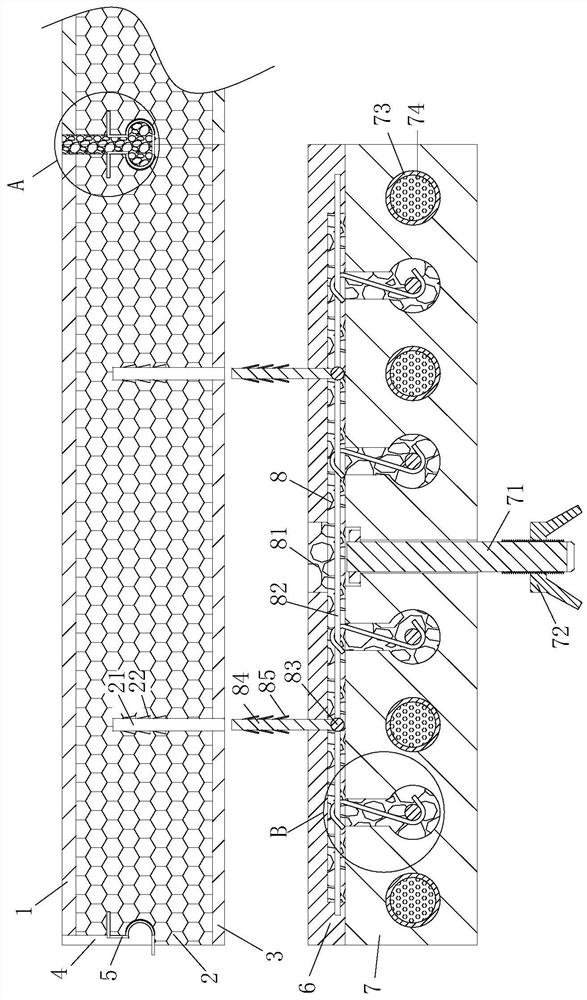

[0032] As an embodiment of the present invention, first prestressed rods 82 arranged in parallel are arranged between the left and right walls of the grouting cavity 8 , and there are connecting first prestressed rods 82 between the front and rear walls of the grouting cavity 8 . The second prestressing rod 83 of the stressing rod 82, the second prestressing rod 83 and the first prestressing rod 82 are vertically arranged, and the connection between the second prestressing rod 83 and the first prestressing rod 82 is connected with the insertion rod 84 lower ends are fixedly connected. Through the prestressing force of the second prestressing rod 83 of the first prestressing rod 82, the outward pulling force of the insulation board to the inserting rod 84 is counteracted, and the transition board is squeezed with the pulling force of the inserting rod 84 after the poured concrete is solidified to avoid If the transition plate is damaged, the bearing capacity of the transition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com