Attached safety operation protection platform for building construction

A technology for safe operation and construction. It is applied in construction, building structure, accessories of scaffolding, etc. It can solve the problems of hidden danger, loss and inconvenient operation of construction workers, achieve safe and reliable lifting operation, improve stability and performance. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

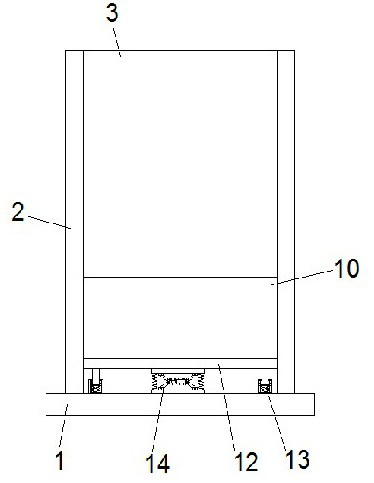

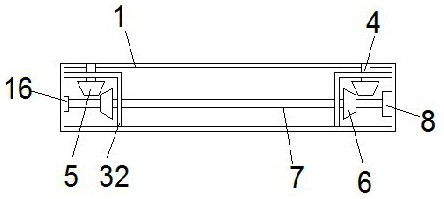

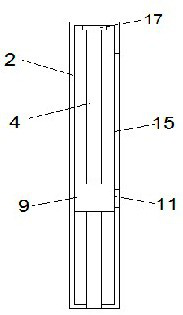

[0027] see Figure 1-5 According to an embodiment of the present invention, an attached safety work protection platform for building construction includes a base 1, a support frame 2 is symmetrically provided on the top of the base 1, and a baffle plate is fixed between the top ends of the support frame 2 3. The inside of the support frame 2 is provided with a threaded rod 4, one end of the threaded rod 4 passes through the base 1 and extends to the middle of the convex gear-5, and one side of the convex gear-5 meshes with A convex gear 2 6 is provided, and a rotating shaft 7 runs through the middle of the convex gear 2 6. One end of the rotating shaft 7 is connected to the output end of the motor 8, and the motor 8 is fixedly installed on the base. In the seat 1, a lift nut 9 is threadedly connected to the outside of the screw rod 4, and one side of the lift nut 9 is fixedly connected with a slider 11, and a lift platform 10 is fixed between the sliders 11, and the support fr...

Embodiment 2

[0029] see Figure 1-5, for the support frame 2 , the support frame 2 is provided with a chute 15 on the side close to the lifting platform 10 , and the slider 11 is located in the chute 15 and matches with the chute 15 . As for the base 1 , an L-shaped support frame 32 is symmetrically fixed inside the base 1 , and the rotating shaft 7 and the screw rod 4 respectively pass through two ends of the L-shaped support frame 32 . For the base 1, a bearing one 16 is fixed inside the base 1, and the end of the rotating shaft 7 away from the motor 8 passes through the bearing one 16 and extends into the bearing one 16. The inner top of the support frame 2 is fixedly provided with a second bearing 17 , and one end of the screw rod 4 passes through the second bearing and extends to the second bearing 17 . For the buffer mechanism one 14, the buffer mechanism one 14 includes a sleeve 18, and the inside of the sleeve 18 is symmetrically provided with a limit groove 19, and a matching lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com