Patents

Literature

30results about How to "Safe and reliable lifting operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

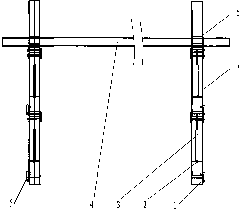

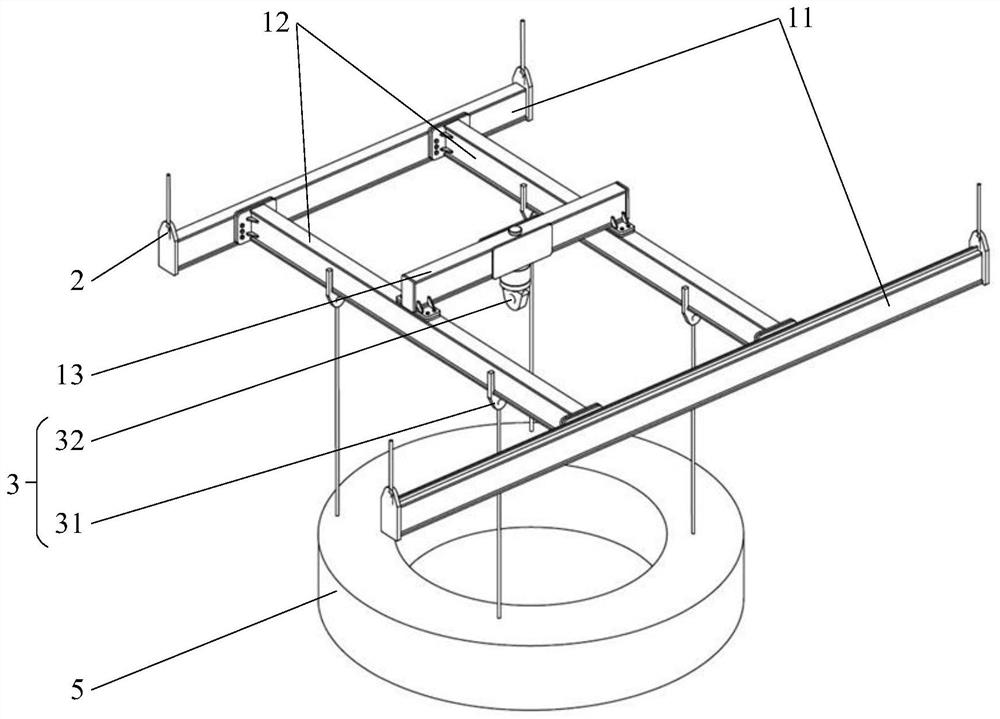

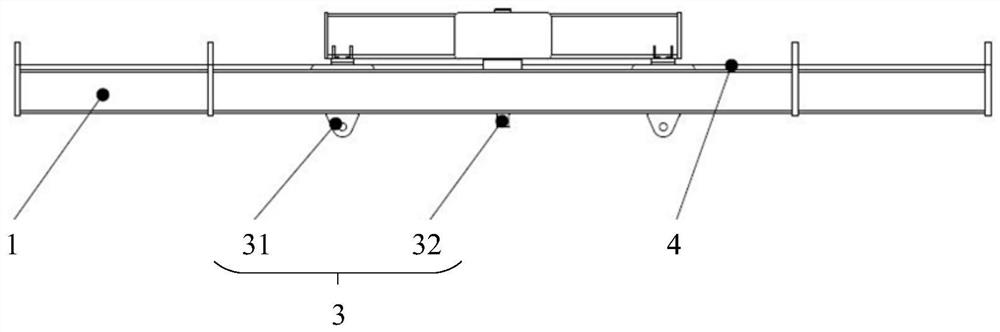

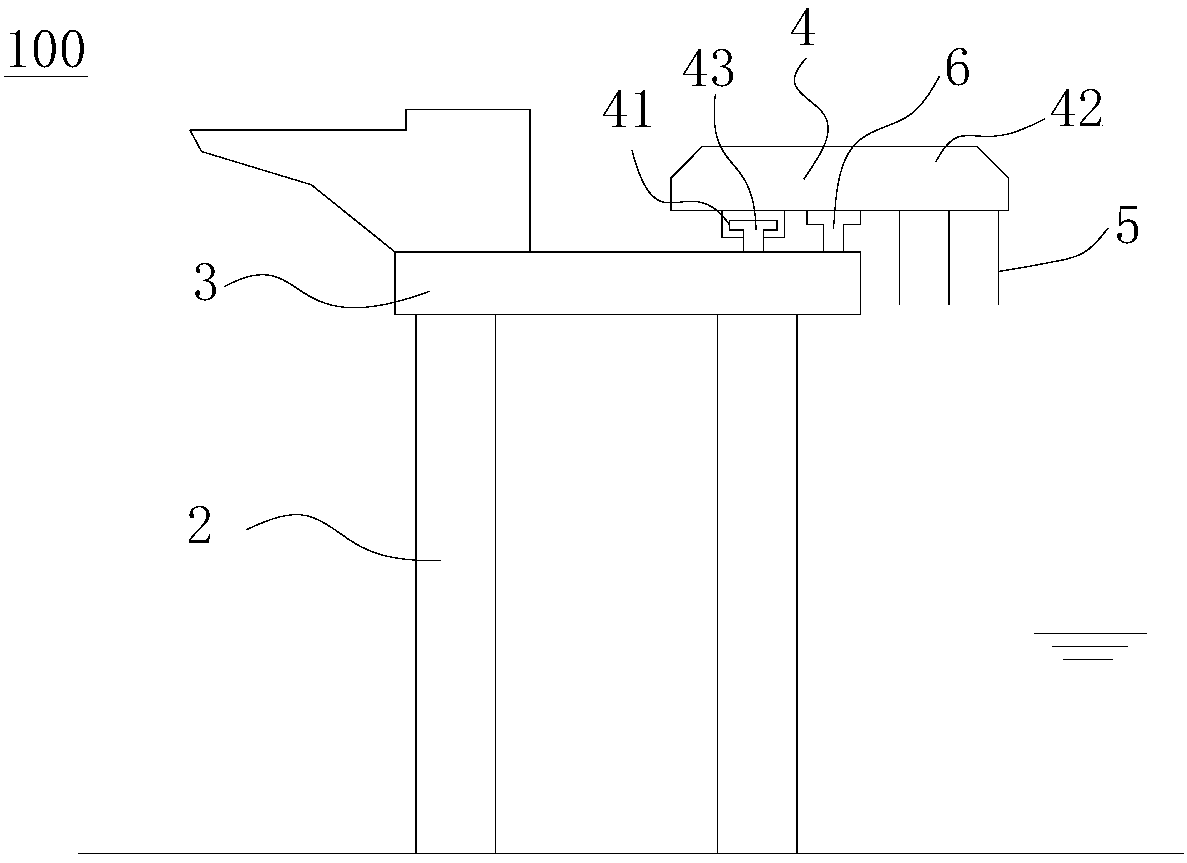

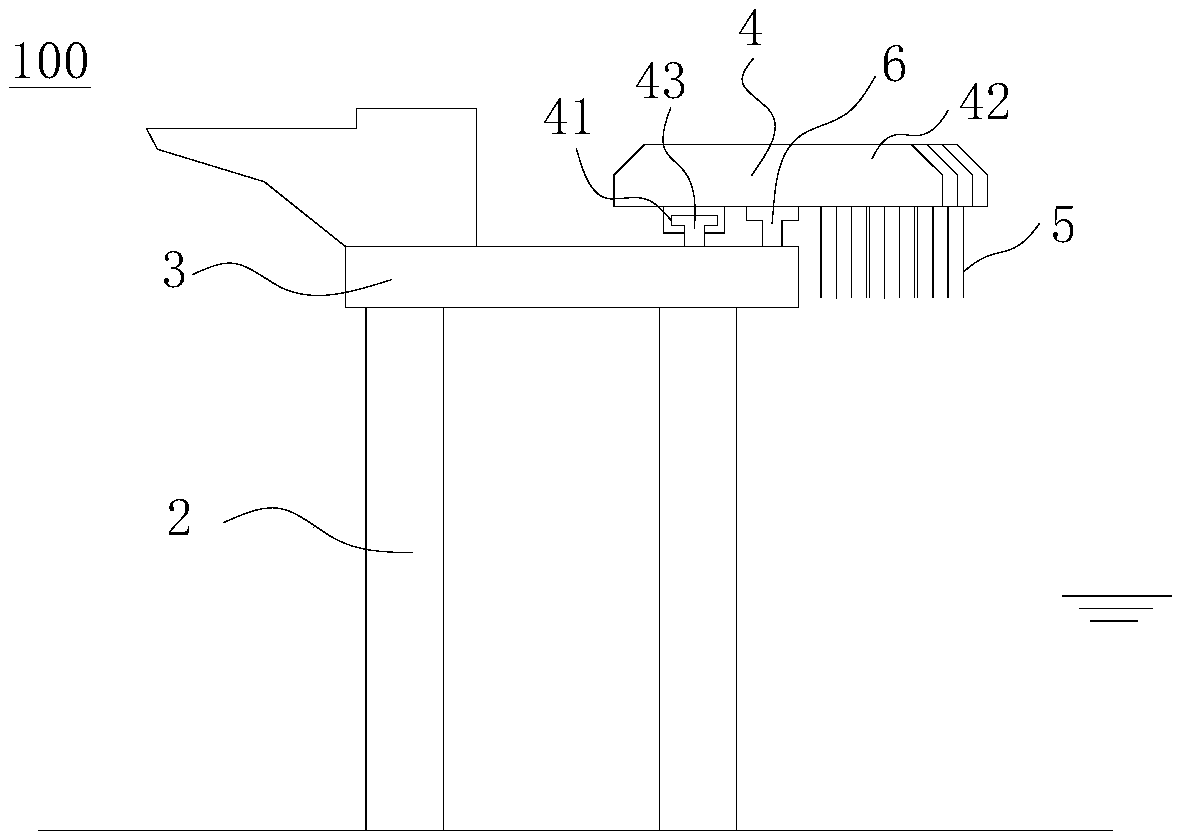

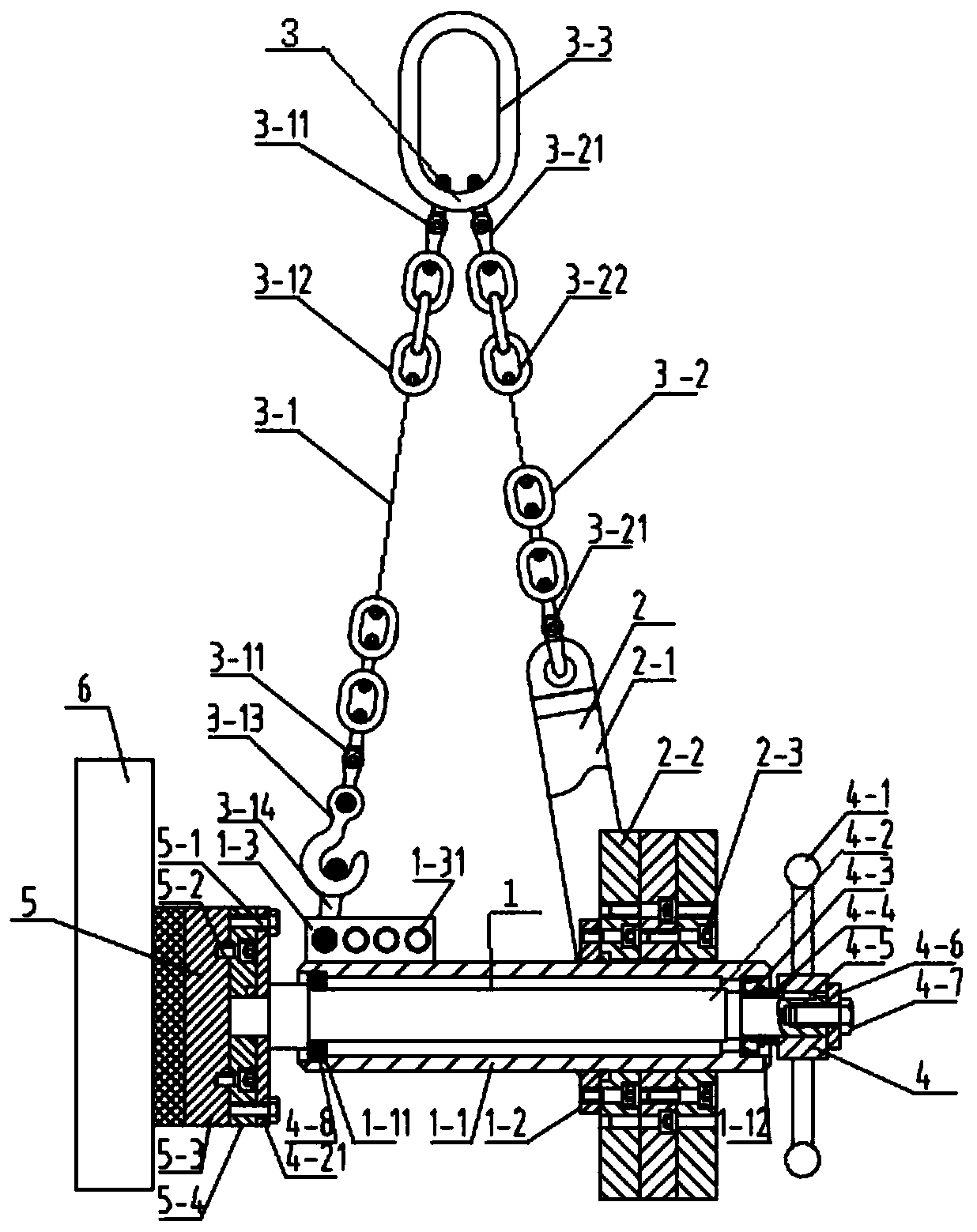

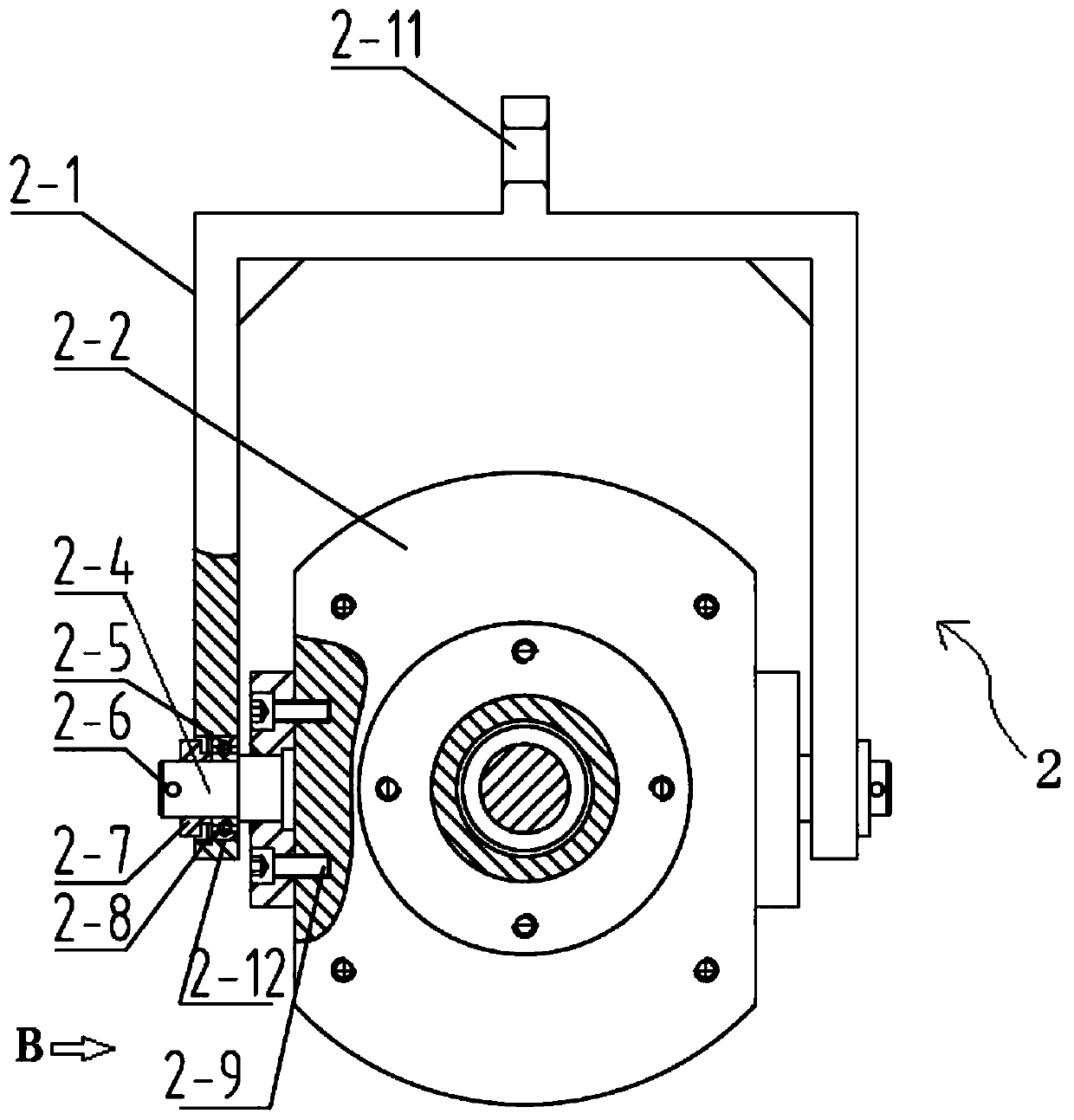

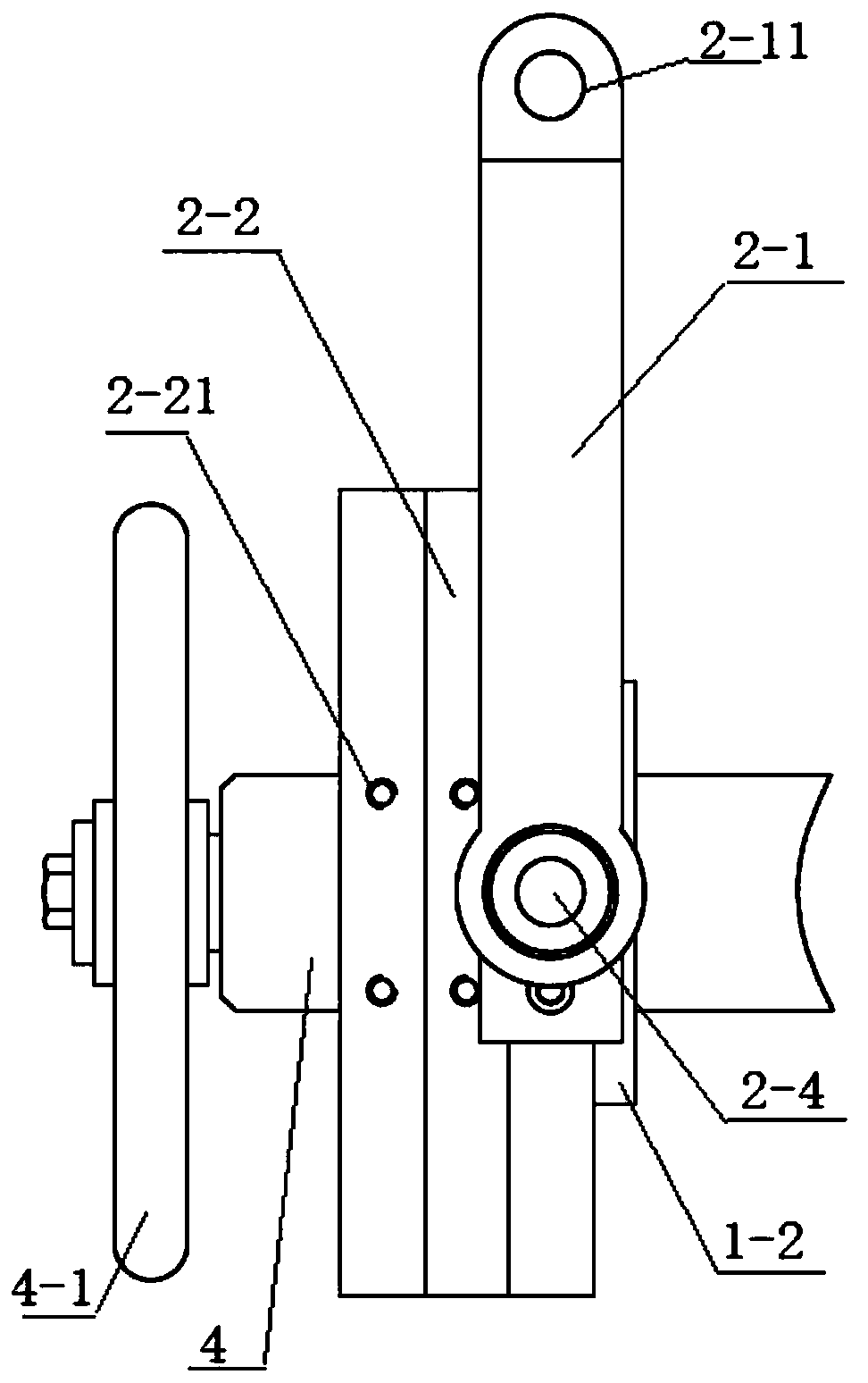

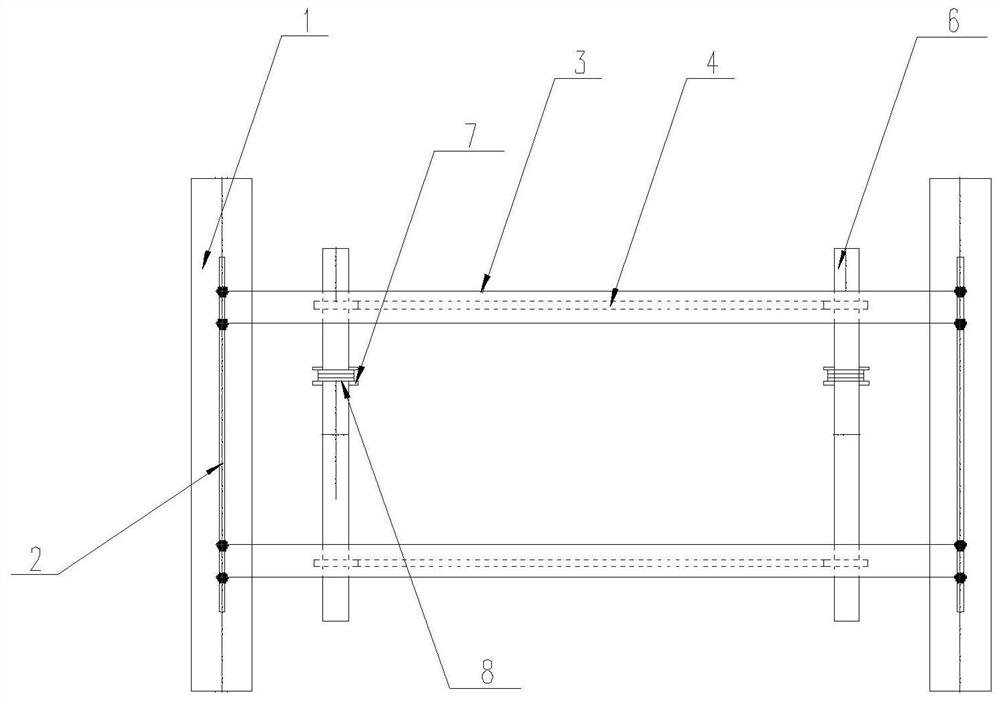

Hoisting method of machine set generator stator and special mechanism thereof

InactiveCN101624164AImprove bending abilityOptimize layoutTravelling cranesWinding mechanismsHoopingEngineering

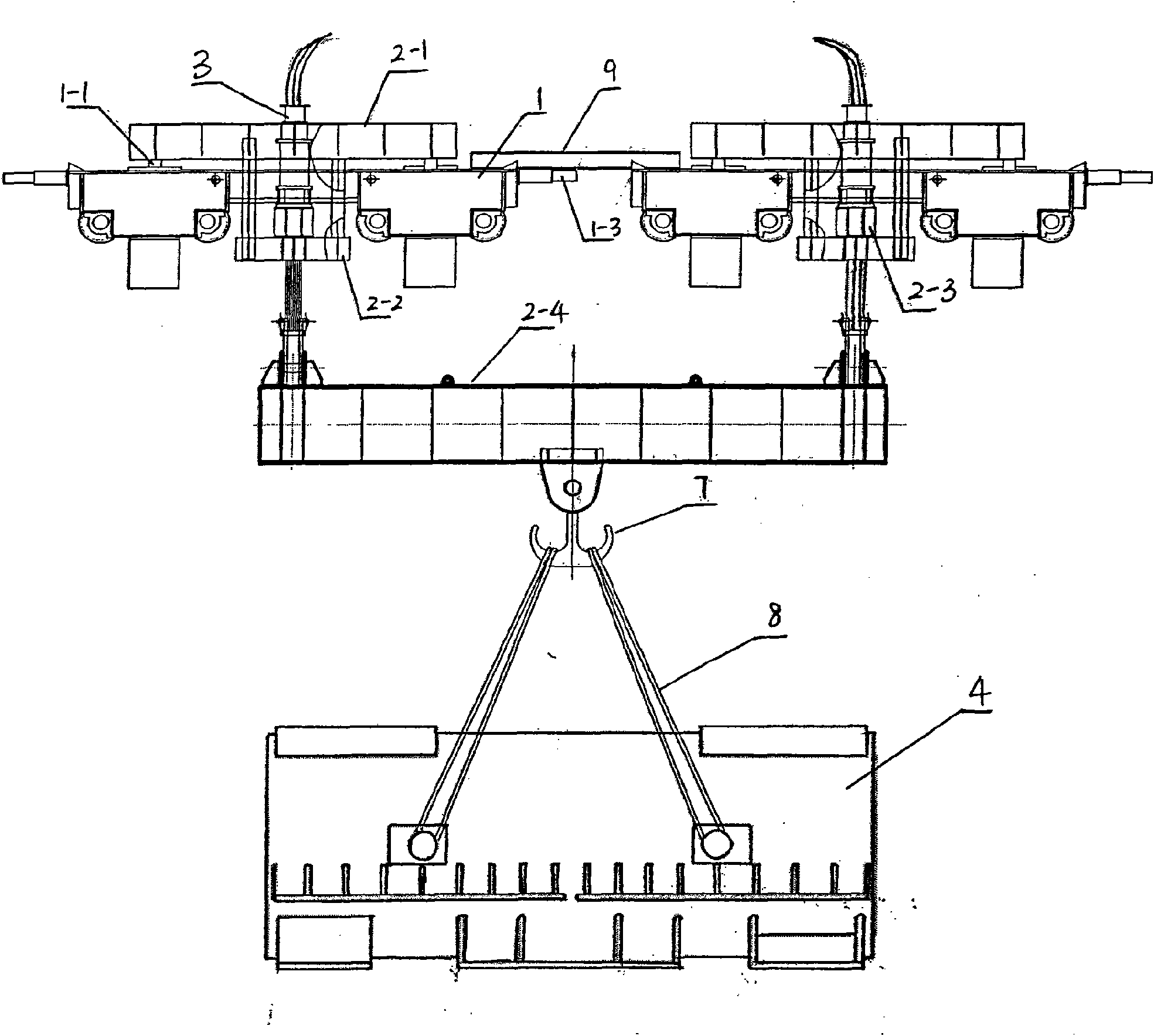

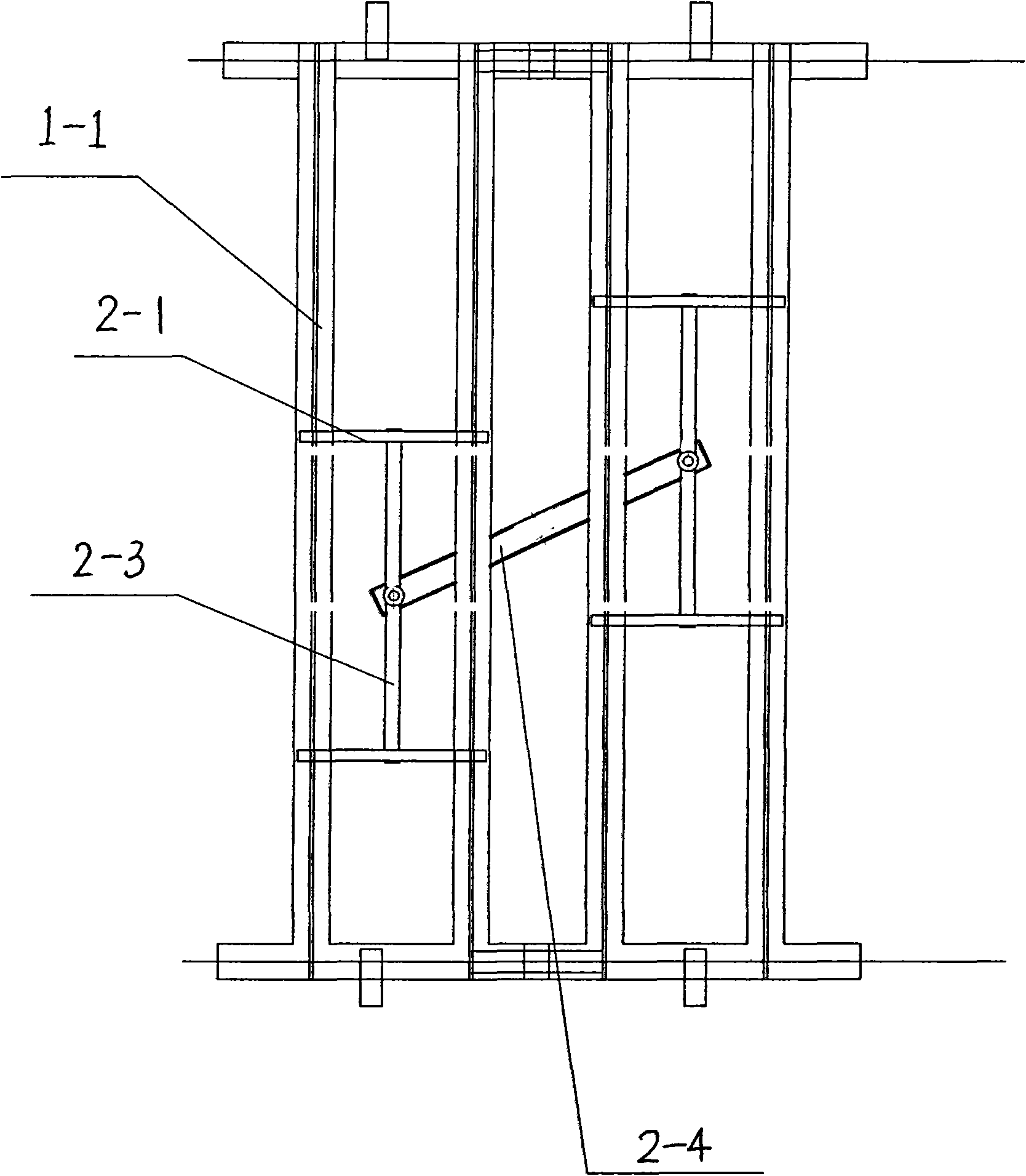

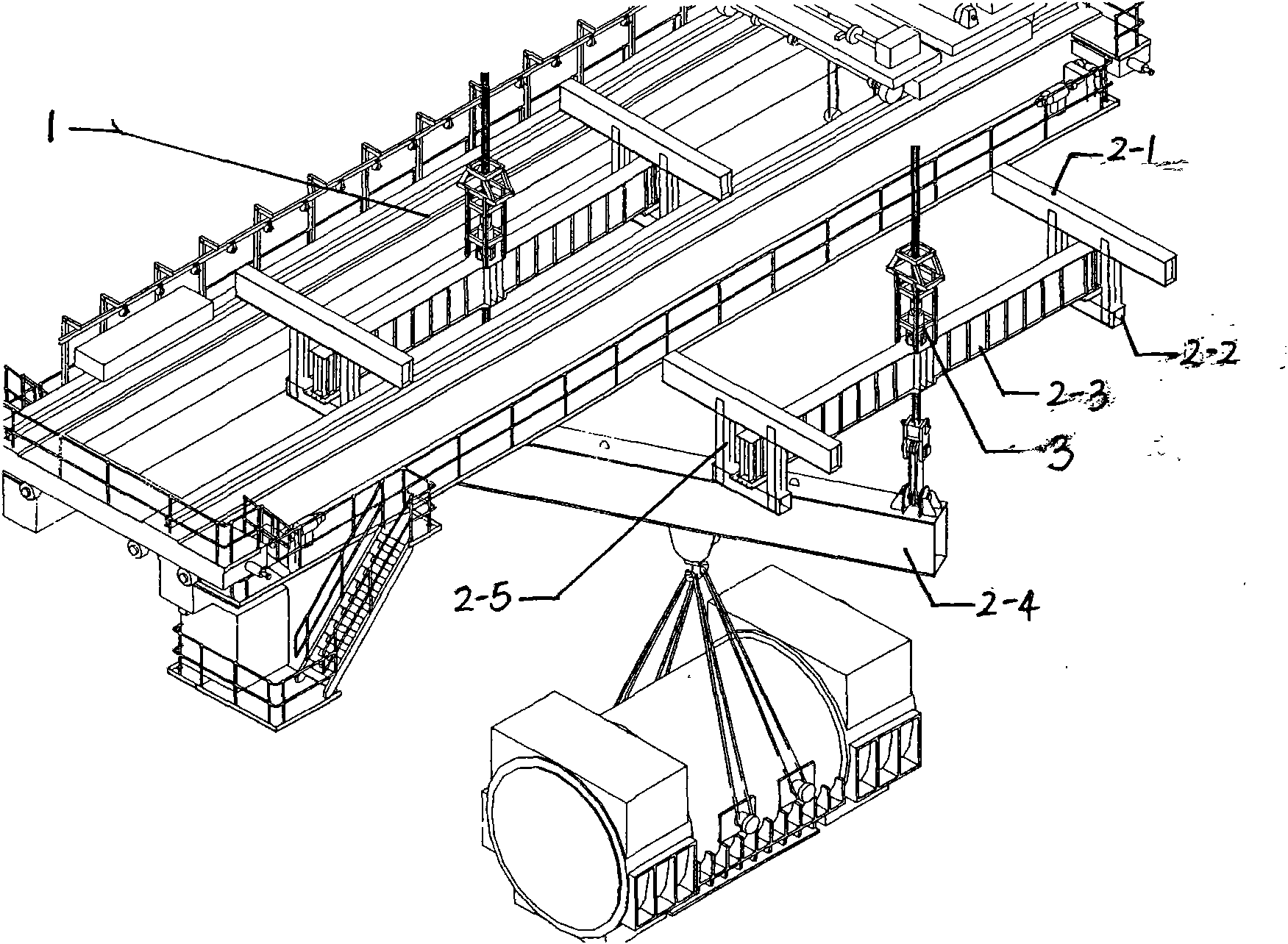

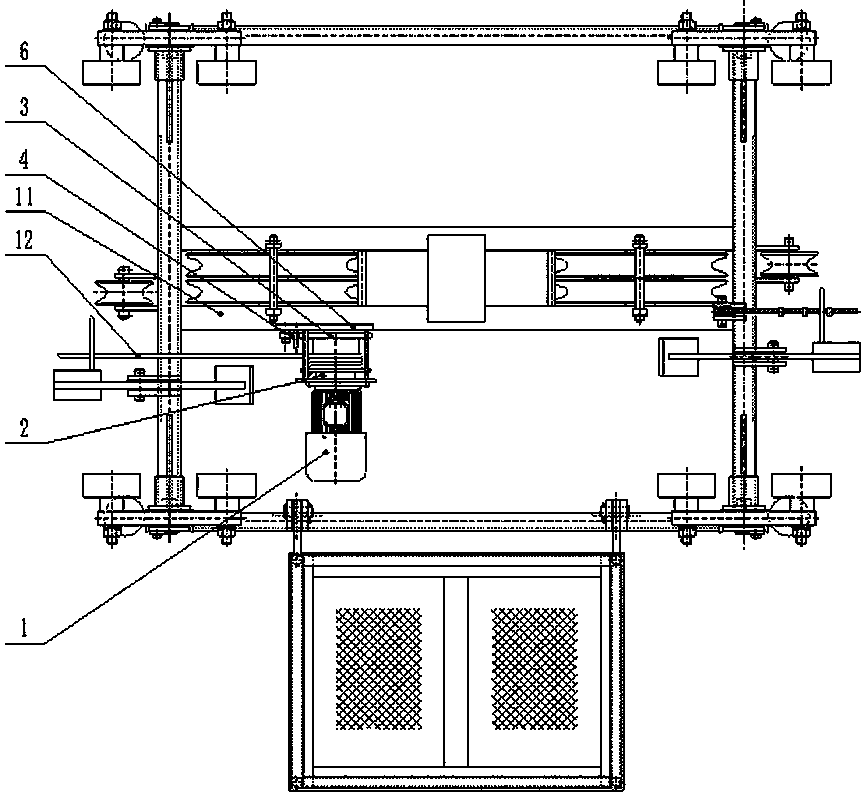

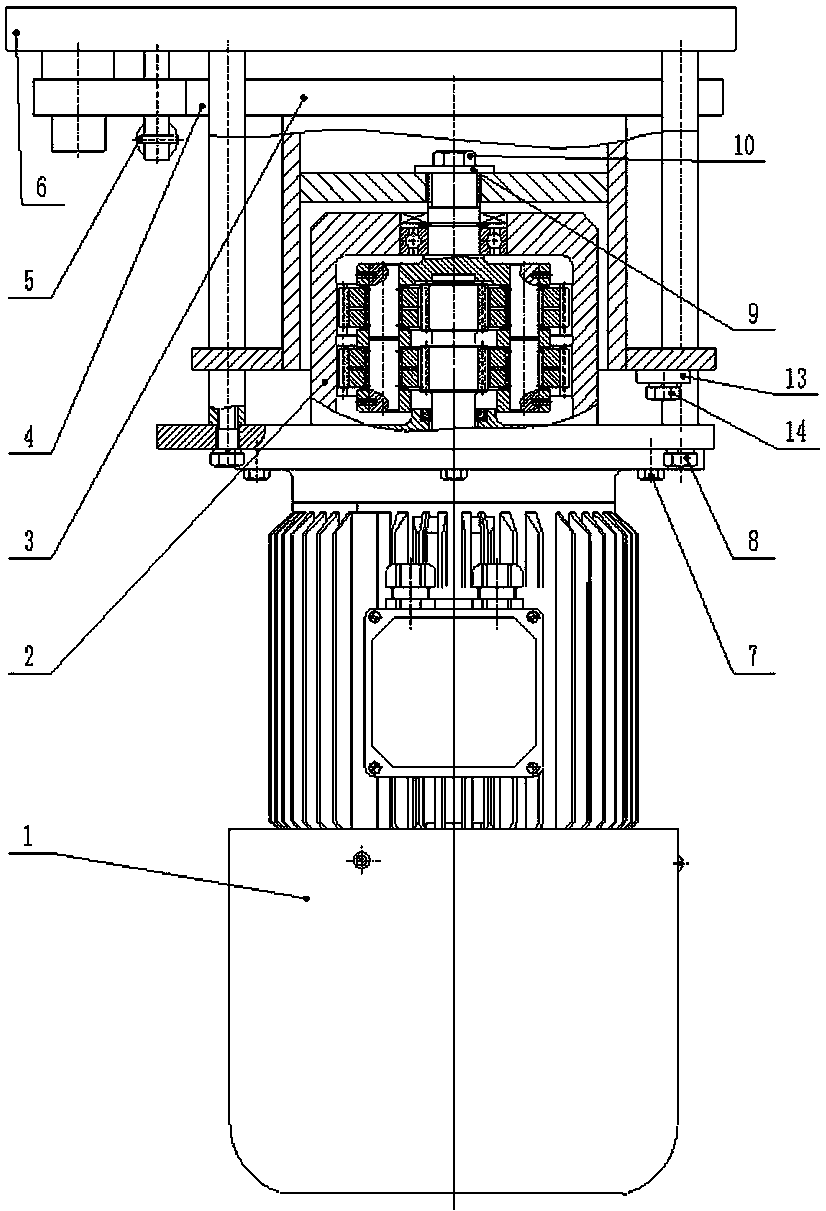

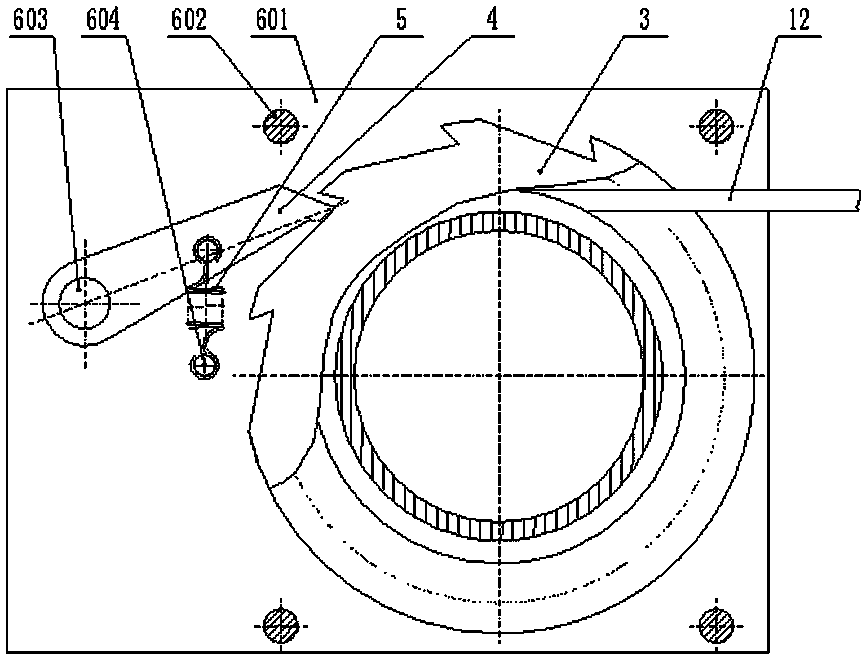

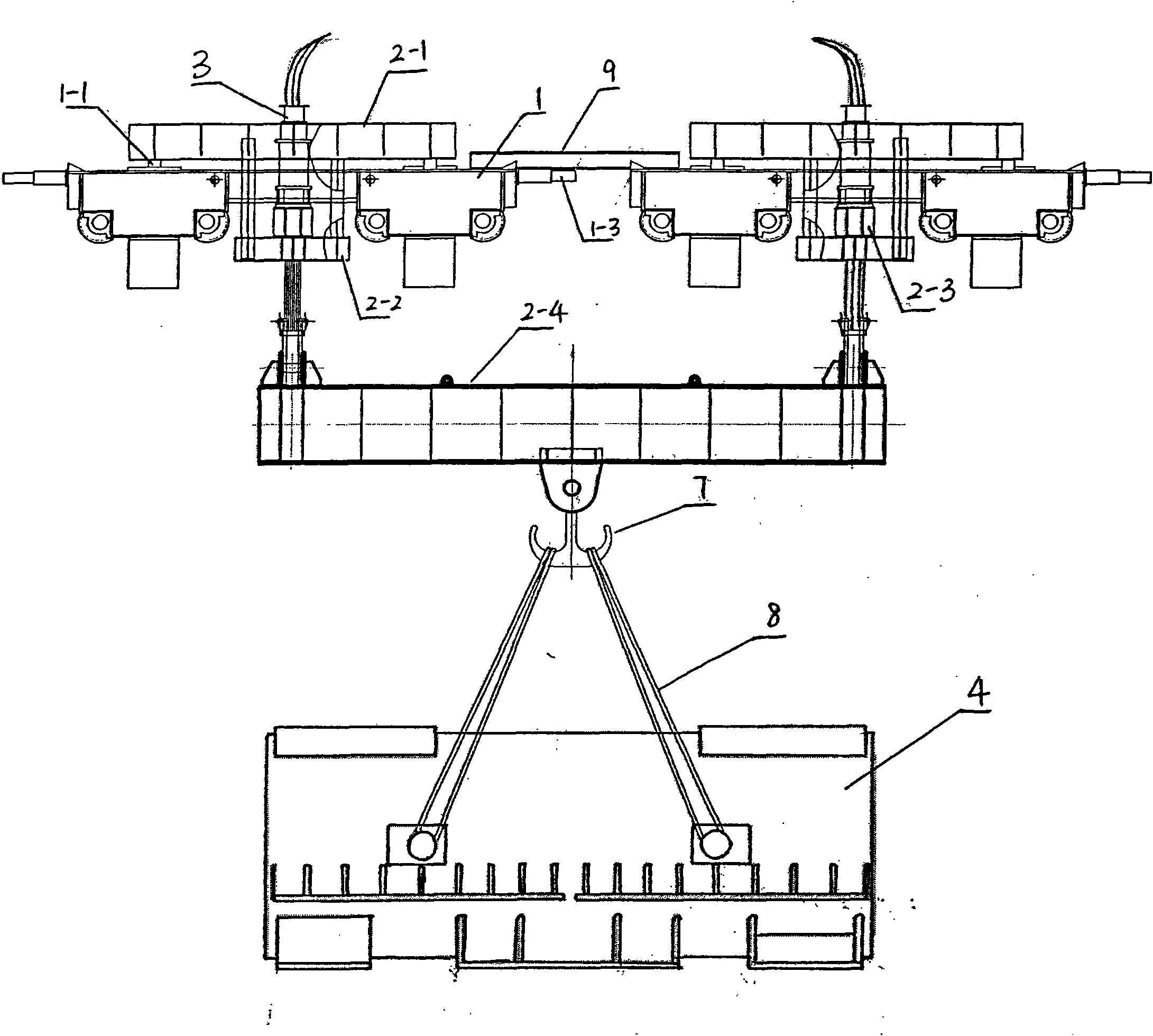

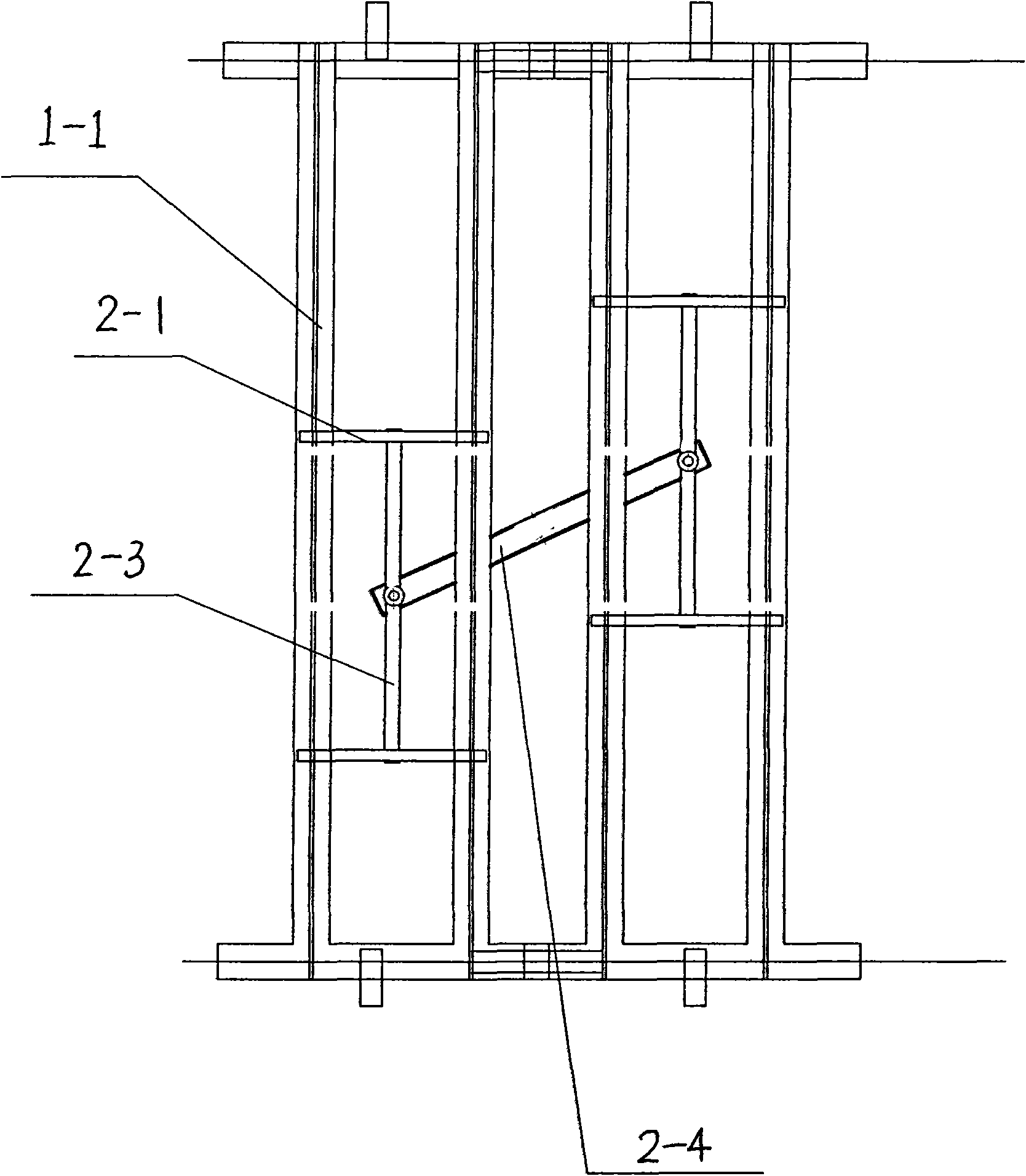

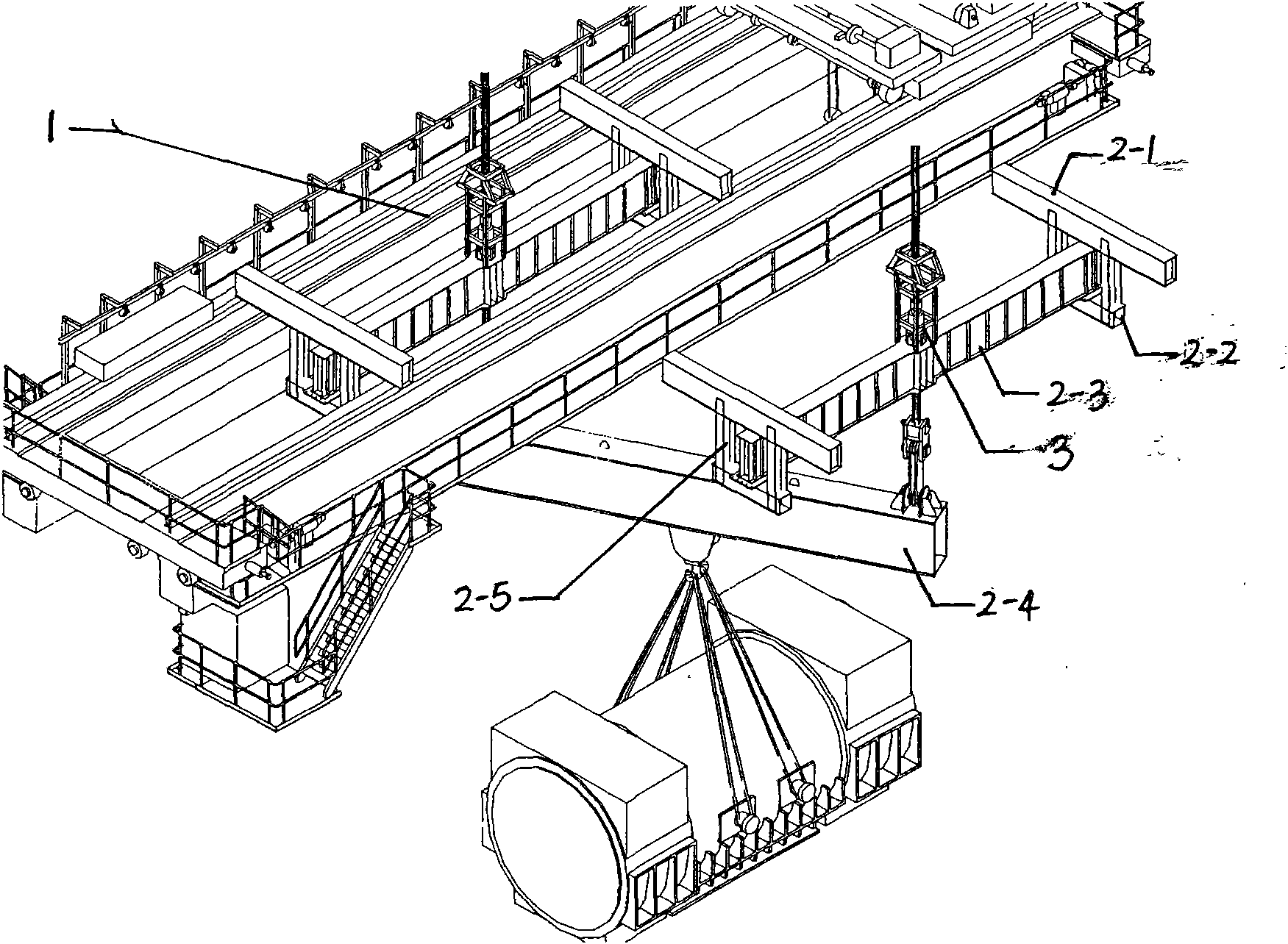

The invention relates to a hoisting method of a machine set generator stator and a special mechanism thereof, which is characterized in that an assistant beam frame structure (2) is in bridge joint on two travelling crane rails (1-1) of two 80-ton travelling crane mechanisms (1) in a main factory, and a hydraulic pressure hoisting device (3) is arranged on the assistant beam frame structure (2); thus, the travelling crane rails change from one-point stress into multi-point stress or region stress so as to improve the anti-bending ability of the travelling crane rails. The invention dispenses with extra hanger frames, a girder of the travelling crane dispenses with re-hooping, and a dolly of the travelling crane dispenses with dissembling and is suitable for installation and stator maintaining and hoisting operations of 300MW-firepower machine set generator stators in China; the invention has the benefits of simple arrangement, short operation time, no need of deferred installation of the main factory structure and quick and safe hoisting operation.

Owner:GUANGDONG POWER ENG

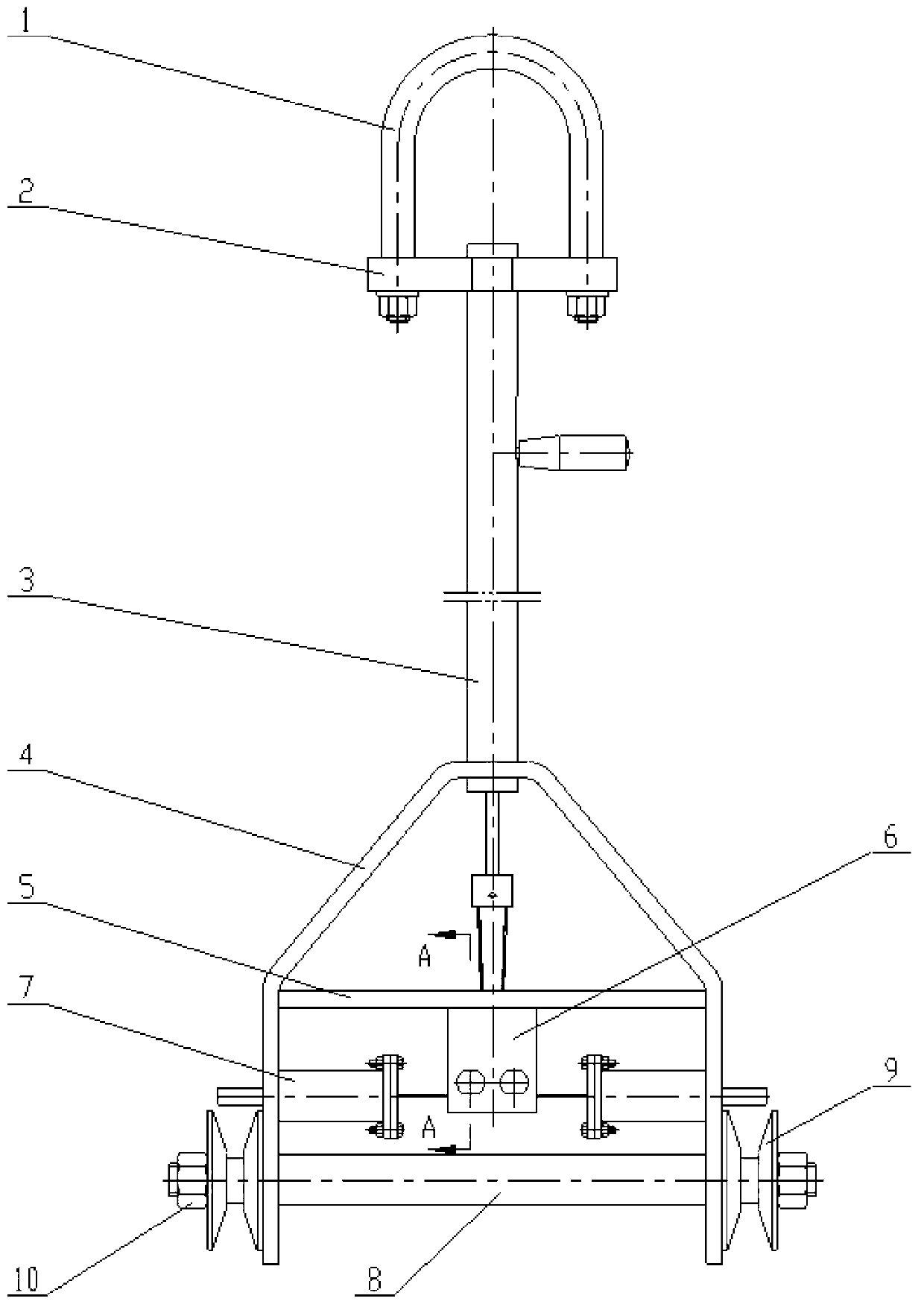

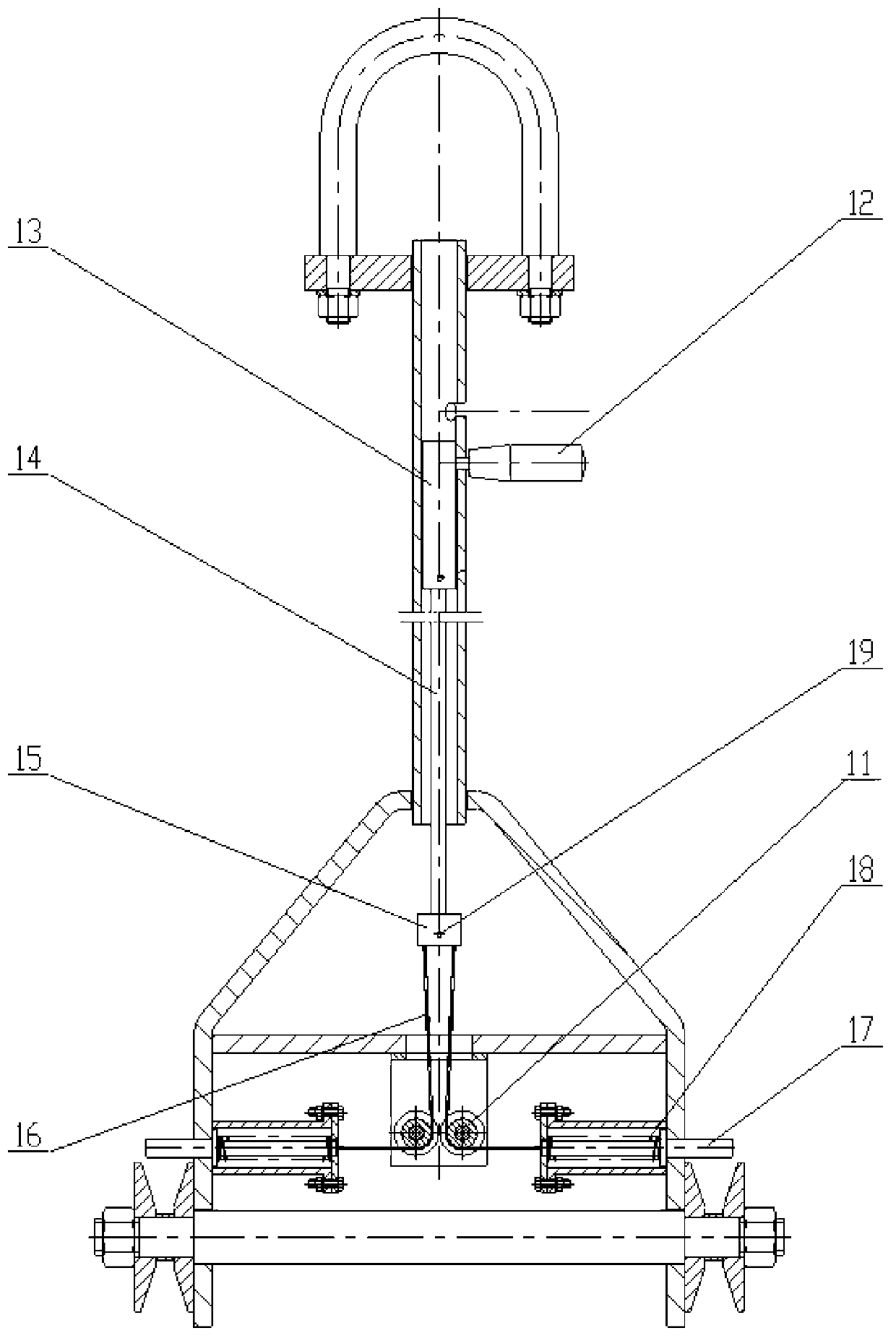

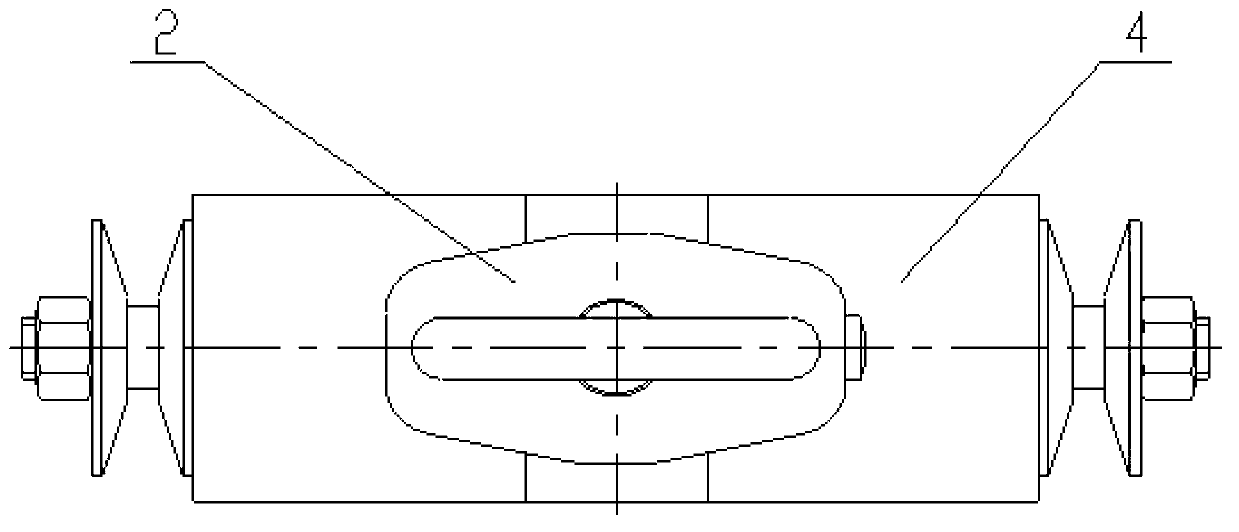

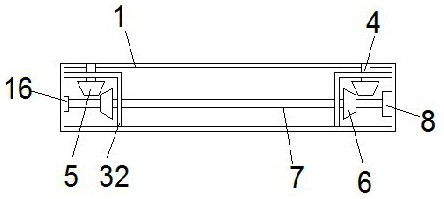

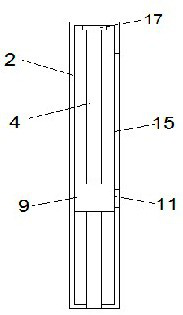

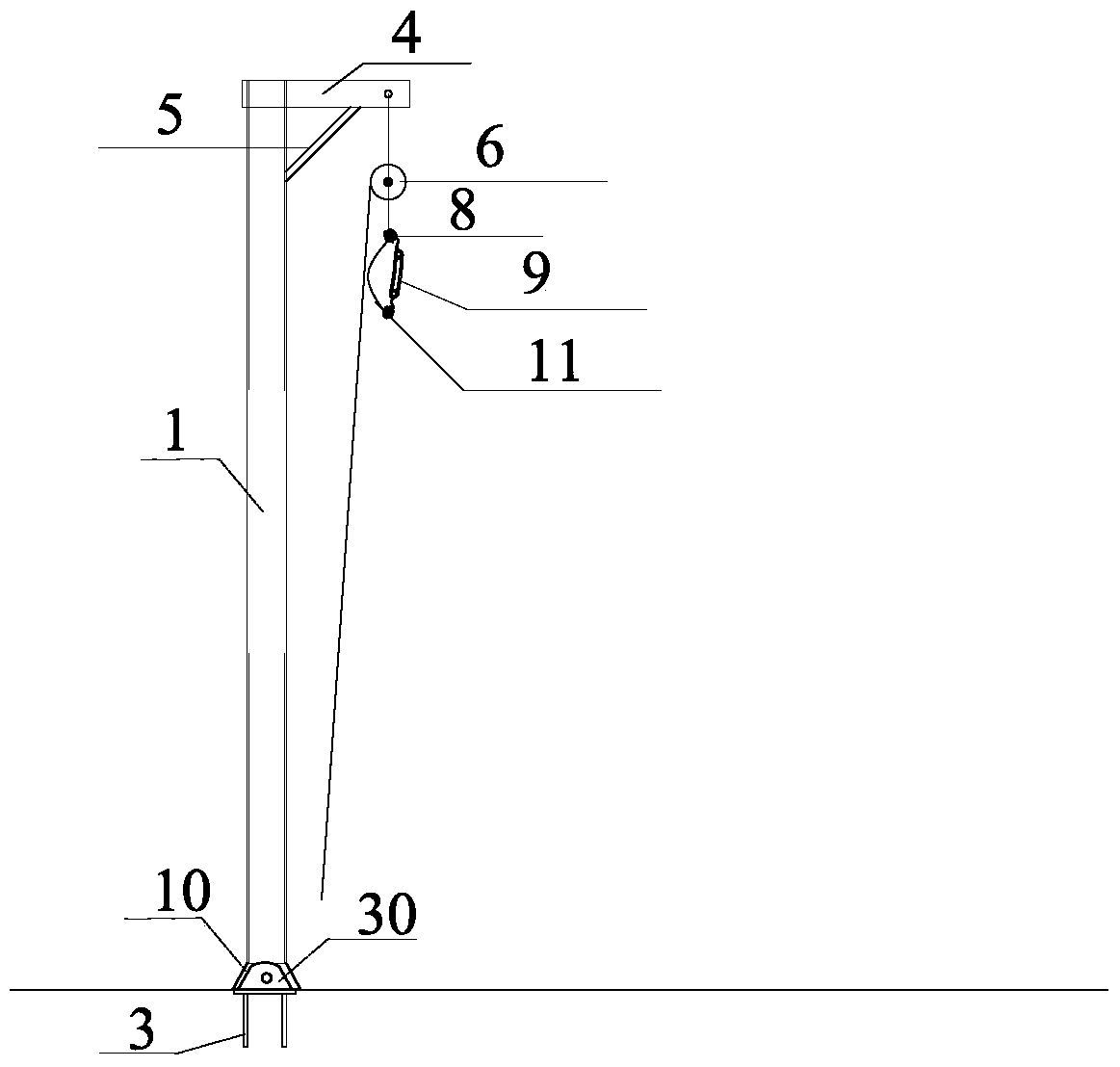

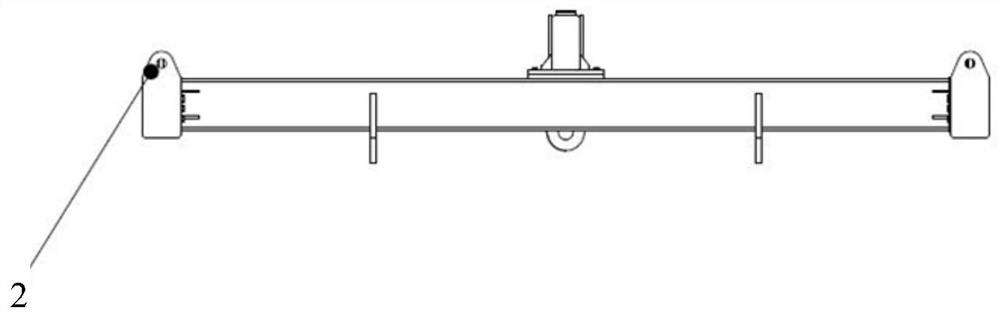

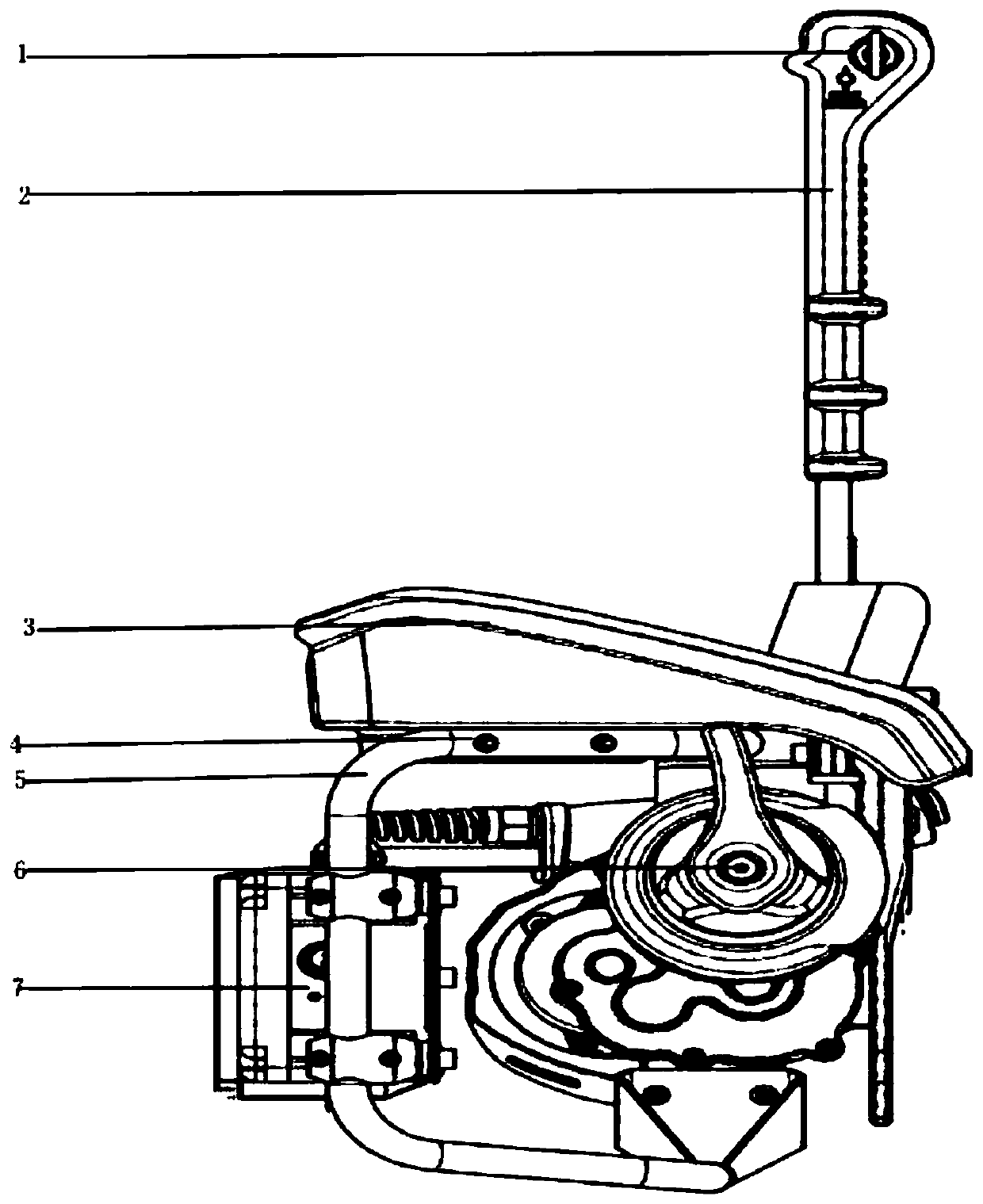

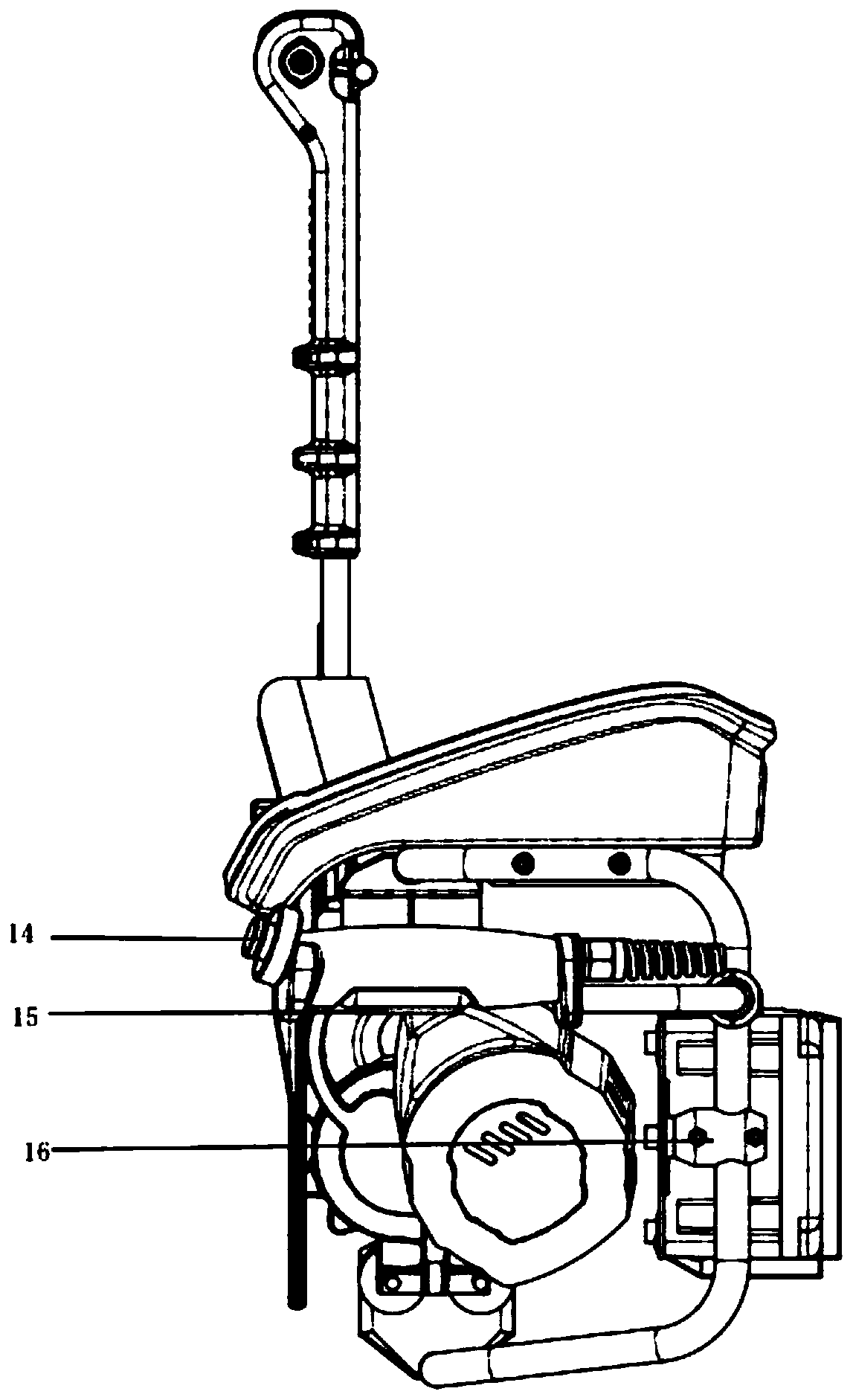

Long-pole spreader

ActiveCN102976197ASafe and reliable lifting operationEnsure safetyLoad-engaging elementsOperation safetyEngineering

The invention discloses a long-pole spreader comprising a hanging ring (1), a hanging wheel rack (4), and hanging wheels (9). The hanging ring (1) and the hanging wheel rack (4) are rigidly connected through a connection pipe (3). A handle (12) which can slide between the first working position and a second working position is arranged on the connection pipe (3). A latch mechanism is arranged on the hanging wheel rack (4). The latch mechanism is connected with the handle (12) through a traction device. When the handle (12) is at the first working position, the latch mechanism extends out and shields wheel grooves of the hanging wheels (9). When the handle (12) is at the second working position, the latch mechanism retracts and leaves the wheel grooves of the hanging wheels (9). According to the long-pole spreader provided by the invention, the long rigid connection pipe is arranged between the hanging ring and the hanging wheel rank, and the latch mechanism is provided on the hanging wheel rank, such that the distance between operators and specific objects is ensured, and the operators are prevented from the harm of radioactivity or toxicity. Also, specific object lifting operation safety and reliability are ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

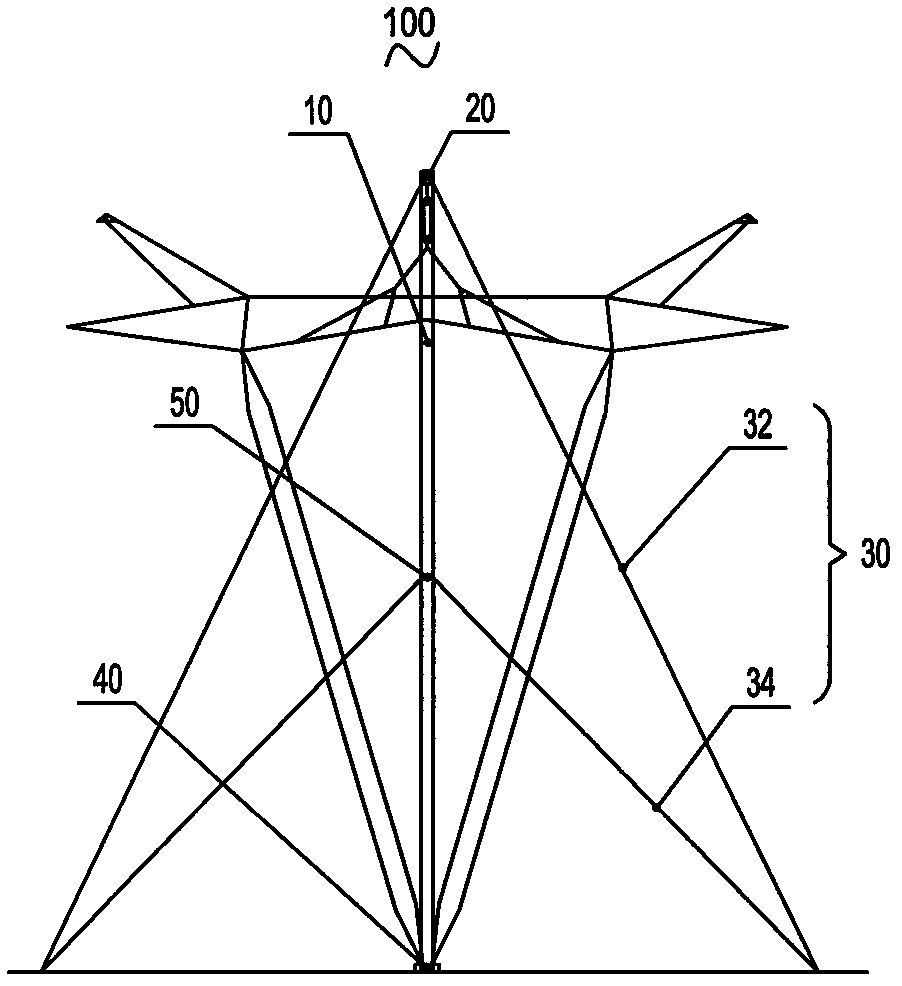

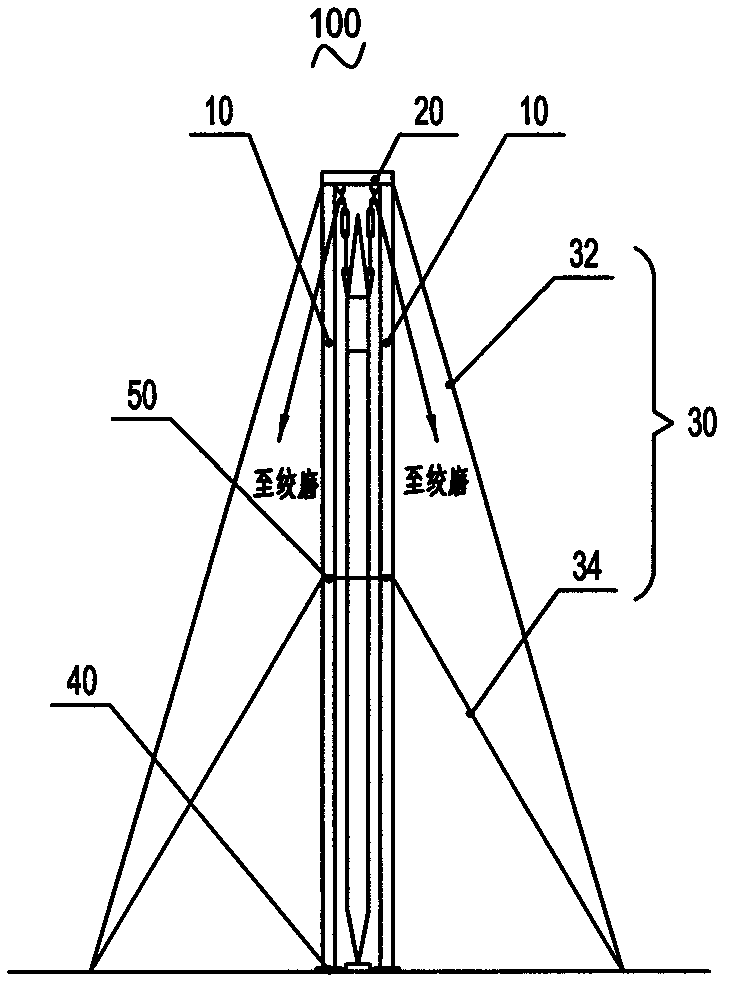

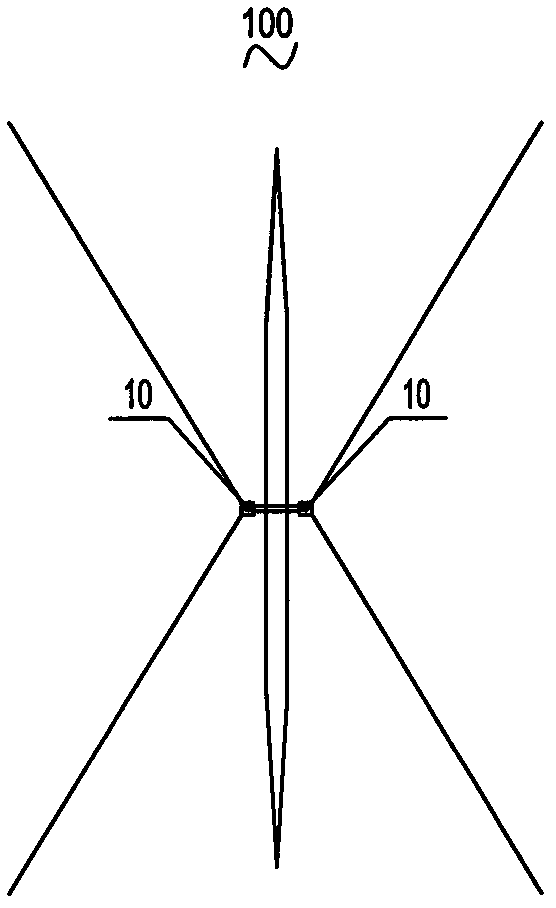

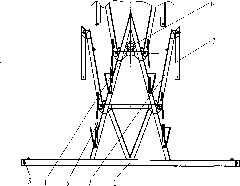

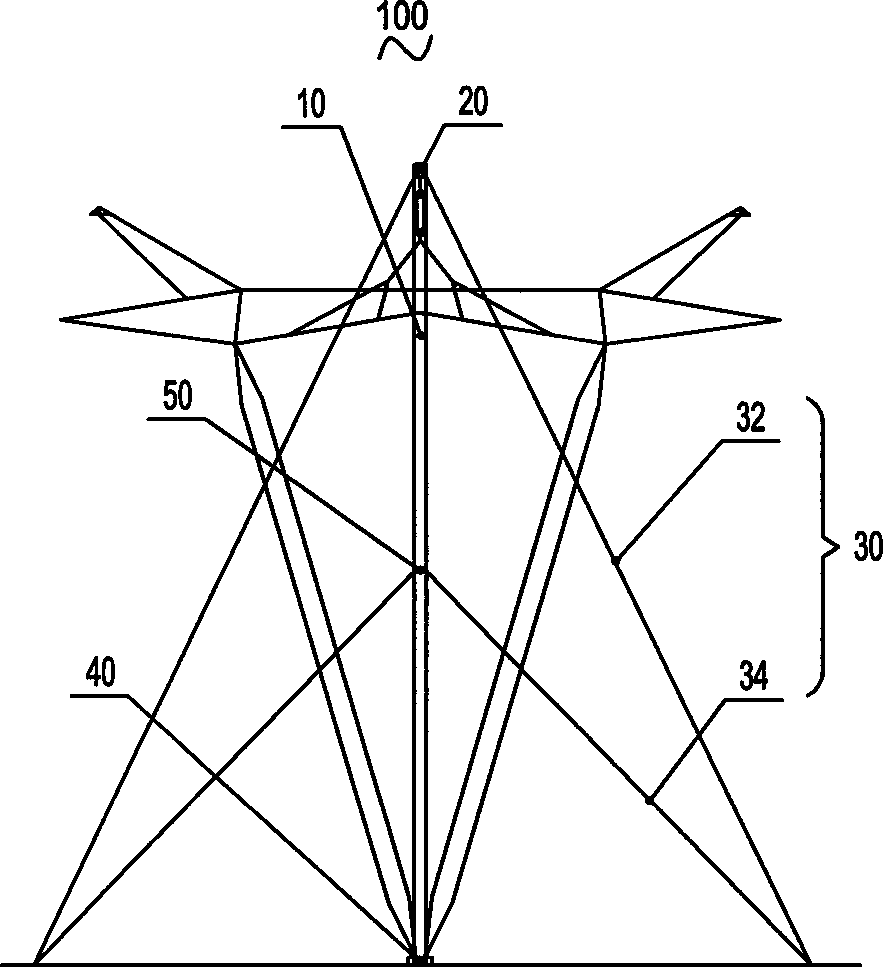

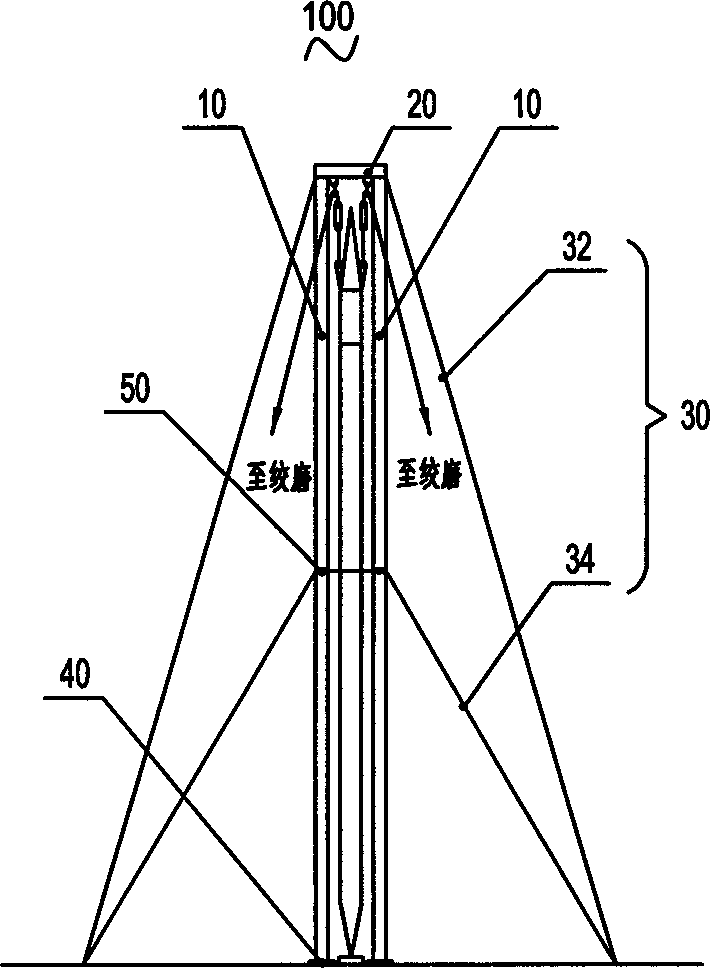

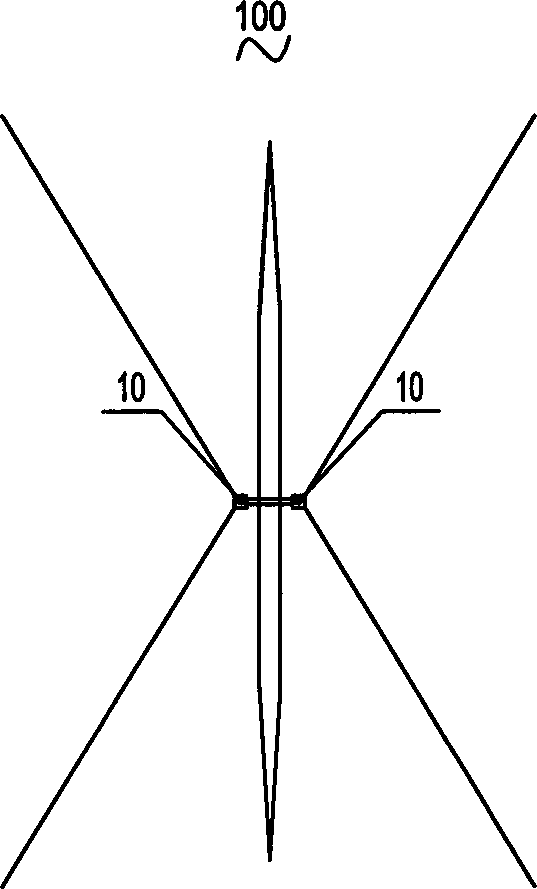

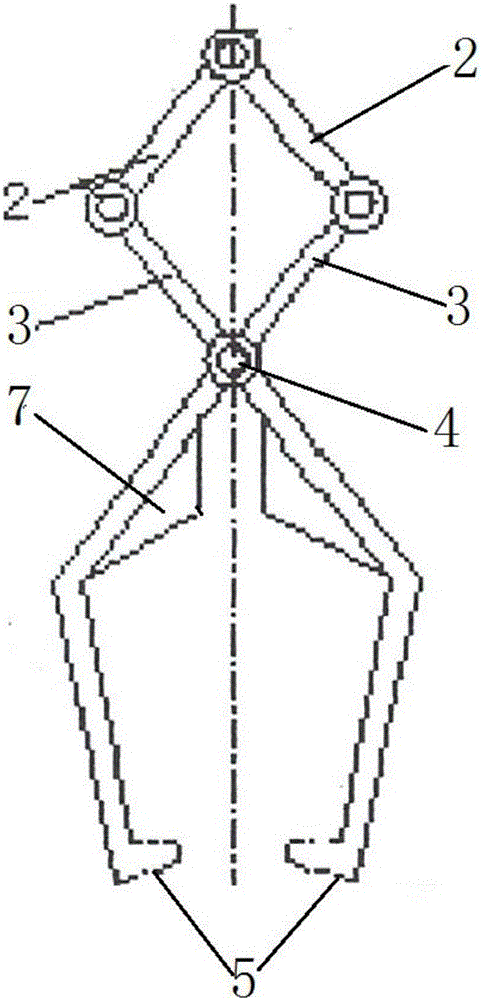

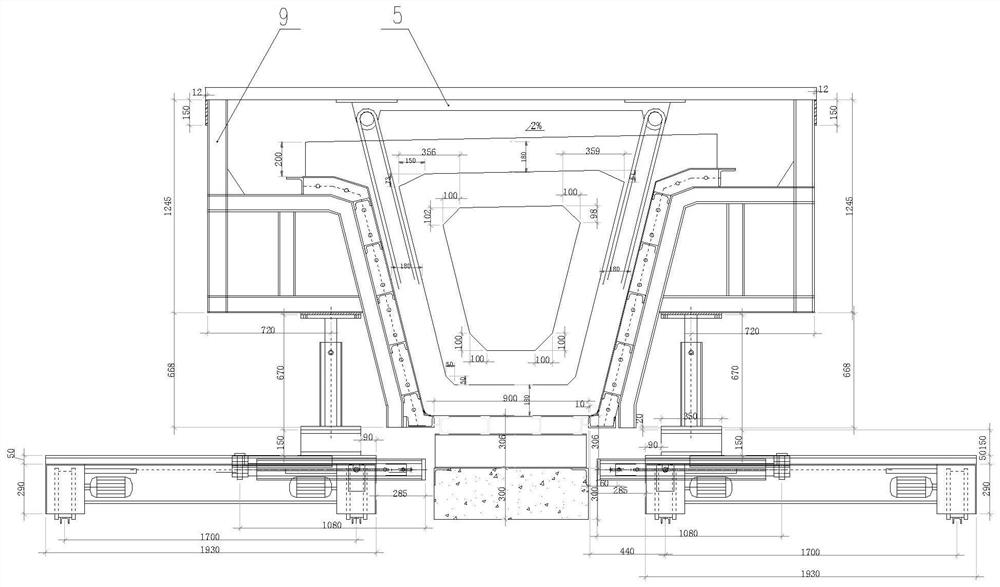

Inversely assembling process for standing stay wire V-type tower

The invention relates to an inversely assembling process for a standing stay wire V-type tower. The process comprises the following steps: assembling a standing door type rack, assembling the head part of the stay wire V-type tower and mounting point rope systems, inversely assembling the stay wire V-type tower, and placing the stay wire V-type tower in place. According to the process, the head part of the stay wire V-type tower is lifted to a certain height above the ground through the door type rack first, then a lower tower segment is assembled below the head part of the stay wire V-type tower, after that, the head part of the stay wire V-type tower continues to be lifted, so as to continue to assemble a second lower tower segment, and the assembling continues until tower legs are assembled. In the process, the door type rack is adopted to inversely assemble the standing stay wire V-type tower in a decomposing manner, so that the load on an appliance is greatly reduced and the hoisting operation is safe and reliable; and the process is suitable for inversely assembling a large-scale stay wire V-type tower and is also suitable for occasions unsuitable to adopt large-scale cranes for operations. The process doesn't need a large-scale crane and is little limited by transportation, and a door type rack hoist system formed by combining machines and tools used frequently for daily construction can replace the large-scale crane to fulfill a task.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

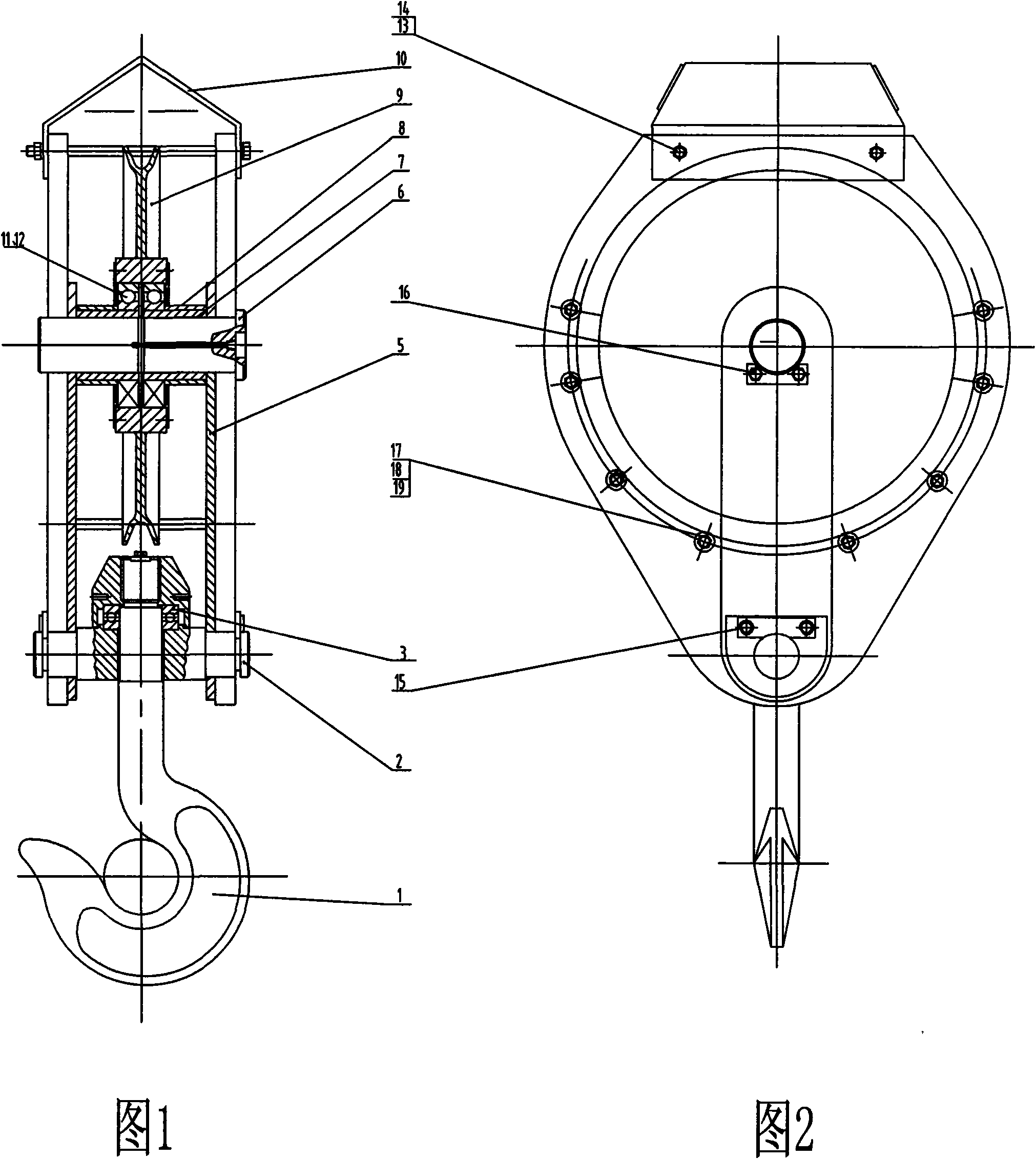

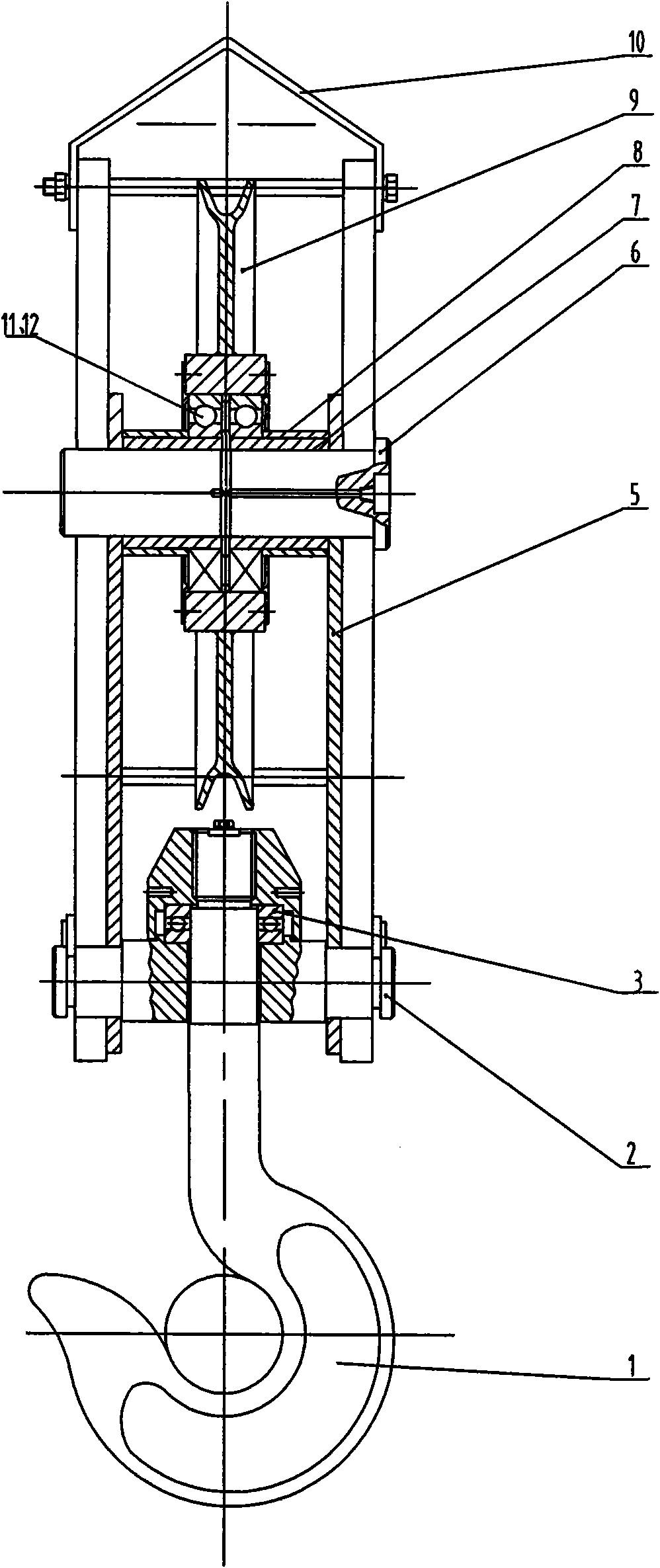

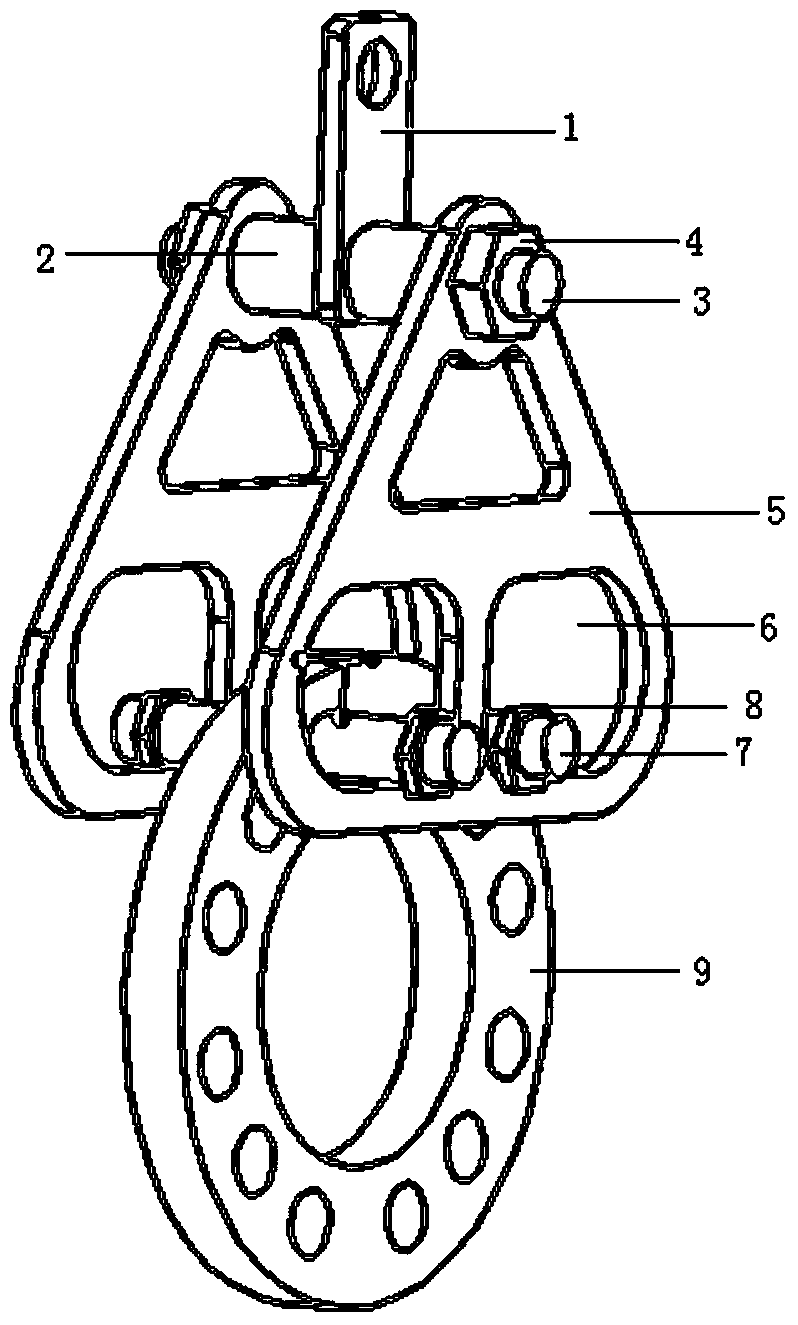

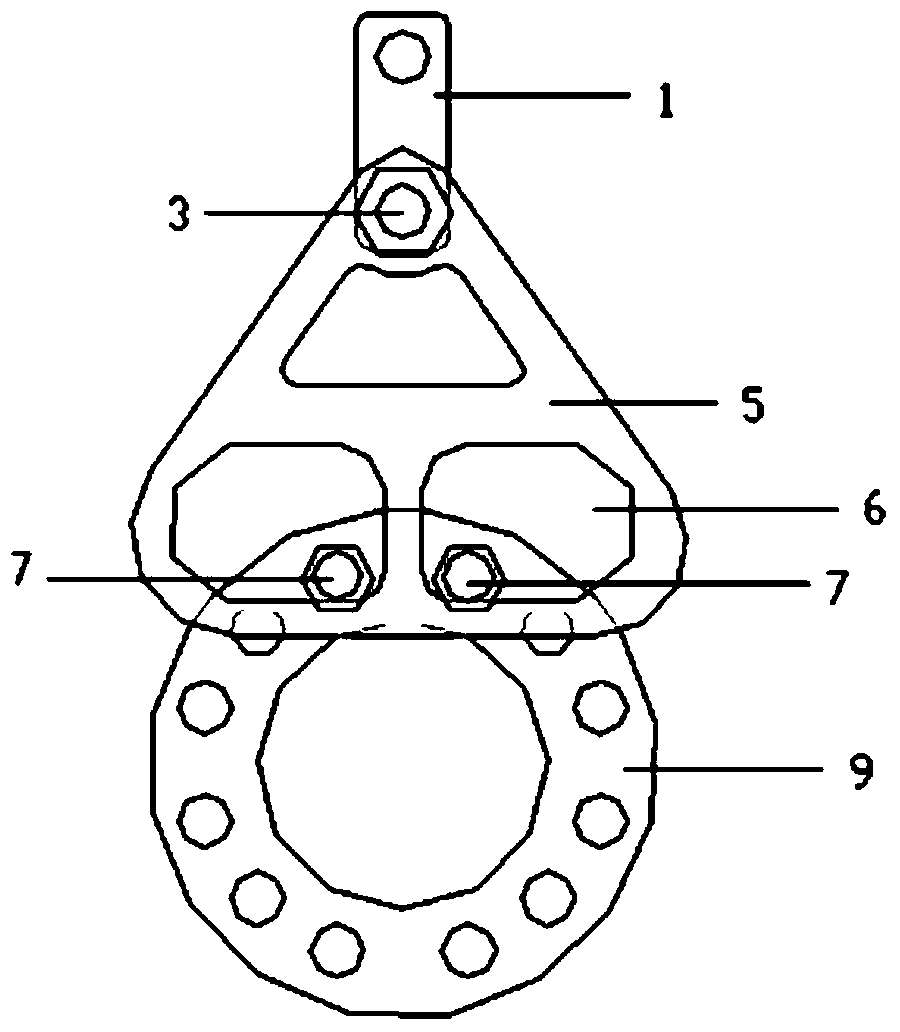

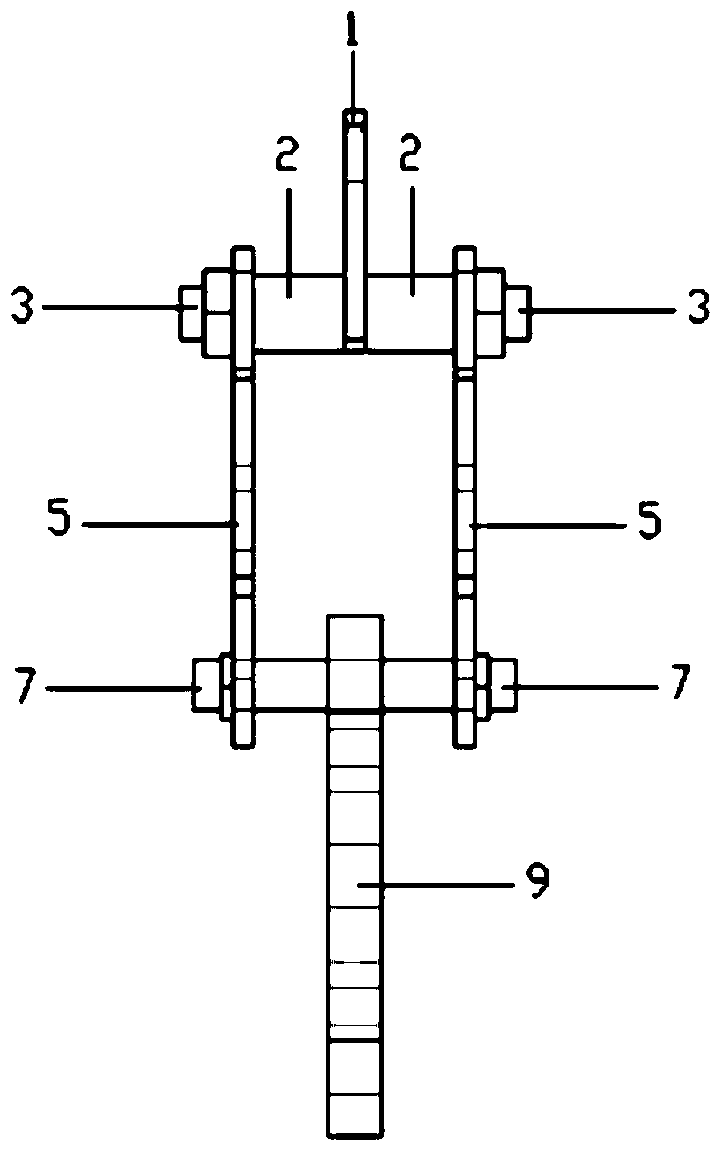

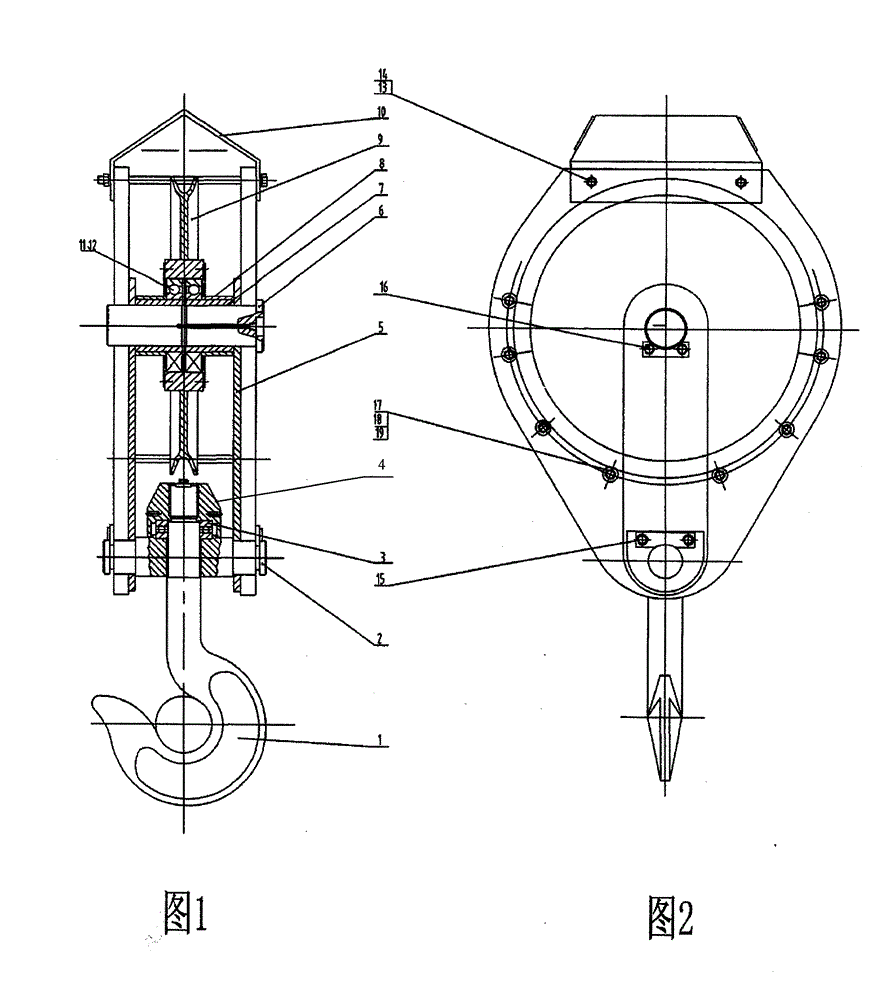

Sheep eye hook device of crane

The invention relates to a sheep eye hook device of a crane, in particular to a hanger used on the crane for grabbing packed cargos, general cargos and other heavy objects, and the sheep eye hook device belongs to the technical field of the hoisting machinery. The hook device is characterized in that yoke plates on both sides are separated by a sleeve and form a hook body through bolts and nuts; a hook is arranged in a cross beam, hoisting nuts are used to compress a bearing installed on the upper part of the hook so as to fix the bearing on the cross beam; the cross beam is installed on the lower part of the hook body, the two ends of the cross beam are clamped by card boards and fixed by bolts. A pulley is installed on the sleeve outside a pulley shaft through a bearing; the sleeve is provided with a support ring; the both ends of the bearing are fixed by a bearing cover plate; the pulley shaft is installed in the middle of the hook body; one end of the pulley shaft is fixed by a shoulder, the other end is fixed by a card board and bolts; and the upper cover of the hook body is fixed by bolts and nuts. The sheep eye hook device has simple, compact and reasonable structure; and by using the hook device, the working intensity of the operating personnel can be lowered, the steel wire rope can be well prevented from sliding outside under an abnormal external force, and the whole hoisting operation can be safe and reliable.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

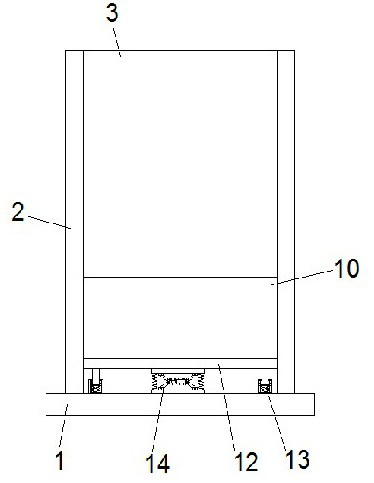

Attached safety operation protection platform for building construction

InactiveCN112127615AImprove stabilityReduce labor intensityScaffold accessoriesBuilding support scaffoldsGear wheelConstruction engineering

The invention discloses an attached safety operation protection platform for building construction. The attached safety operation protection platform comprises a base, supporting frames are symmetrically arranged at the top of the base, a baffle is fixedly arranged between the top ends of the supporting frames, lead screws are arranged in the supporting frames in a penetrating manner, and one endof each lead screw penetrates through the base and extends to the middle of a first convex gear; a second convex gear is meshed with one side of each first convex gear, a rotating shaft is arranged between the middles of the second convex gears in a penetrating manner, one end of the rotating shaft is connected with the output end of a motor, the motor is fixedly installed in the base, the outer sides of the lead screws are in threaded connection with lifting nuts, one side of each lifting nut is fixedly connected with a sliding block, and a lifting platform is fixedly arranged between the sliding blocks; and a buffer seat is arranged between the supporting frames, first buffer mechanisms and a second buffer mechanism are arranged between the buffer seat and the base, and the second buffermechanism is located between the first buffer mechanisms. The attached safety operation protection platform has the beneficial effects that the supporting performance of the buffer seat is greatly improved, and meanwhile, the stability performance of the lifting platform is improved, so that the lifting operation is safer and more reliable.

Owner:QINGDAO BOHAI CONSTR GROUP +1

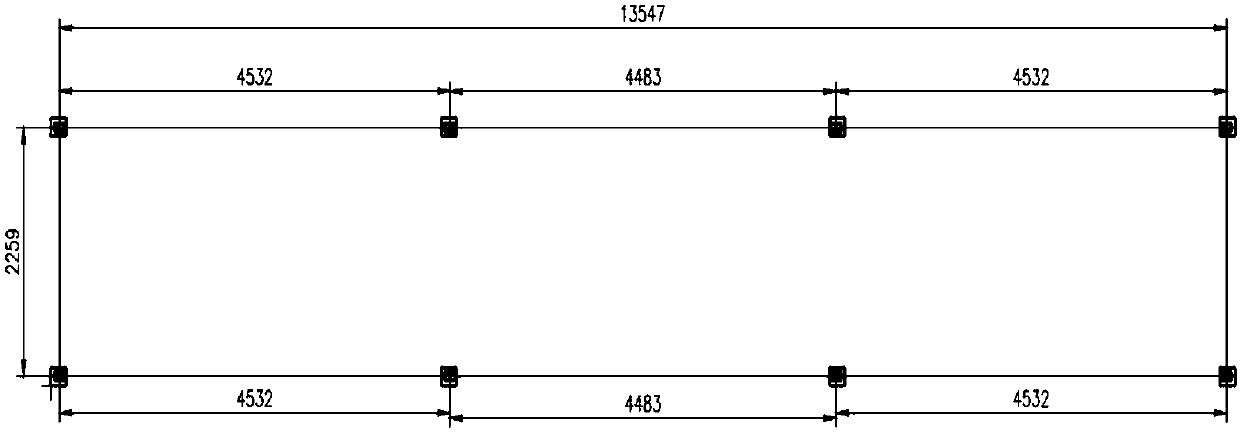

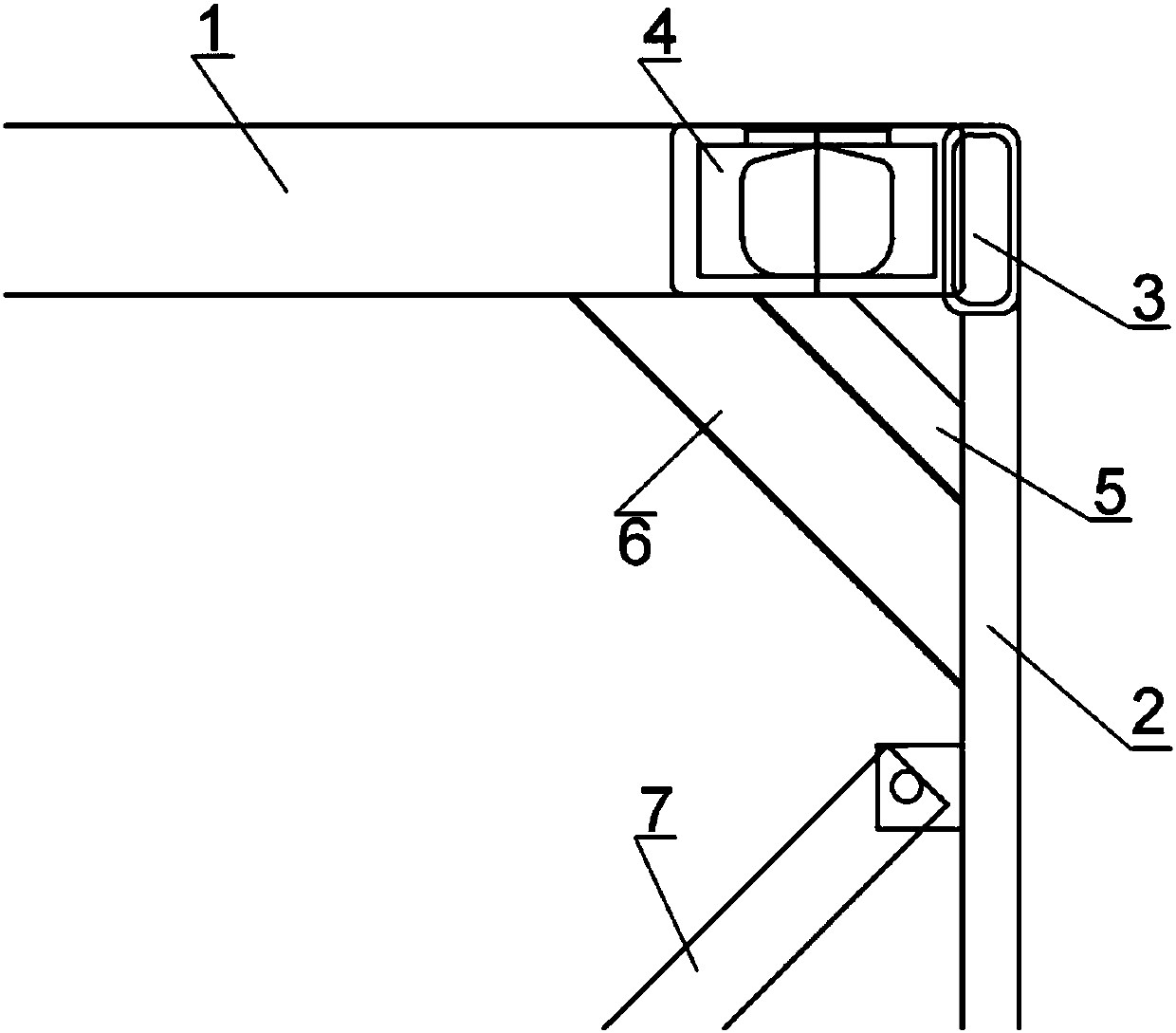

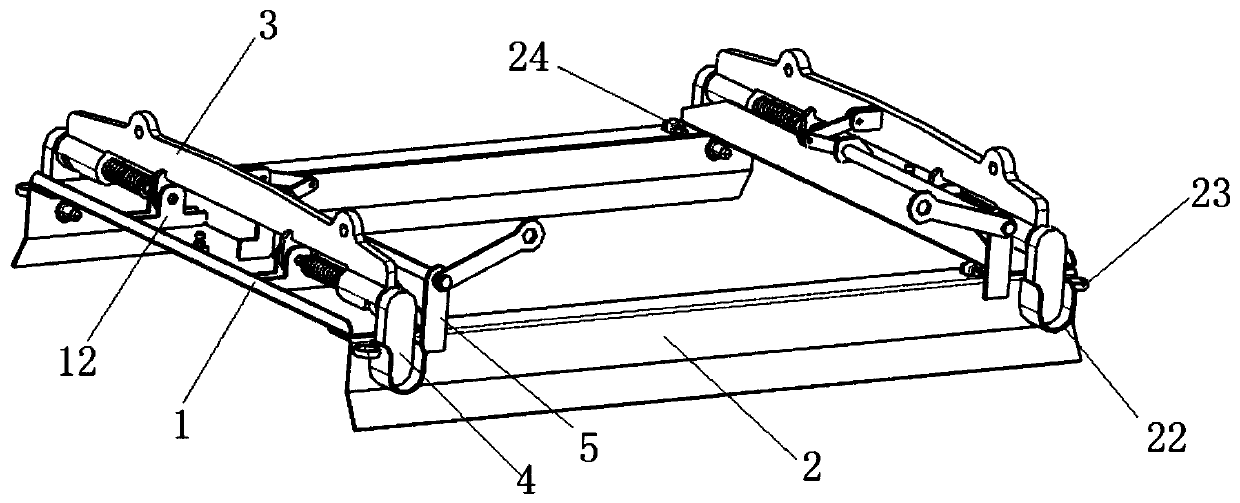

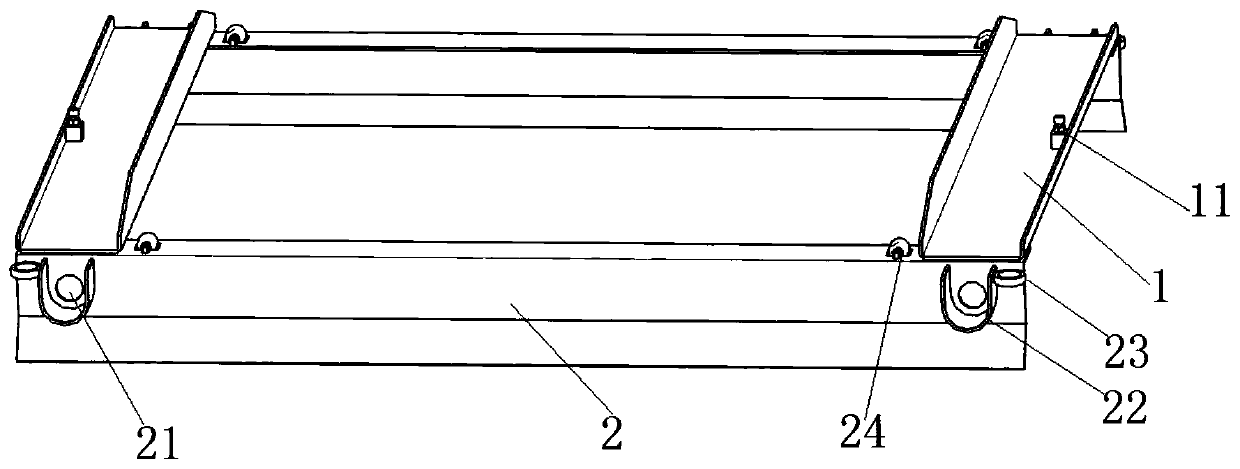

Hoisting locking mechanism and lifting appliance of highway-railway combined transportation van semitrailer

PendingCN107697814ASimple structureSafe and reliable lifting operationTrolley cranesLoad-engaging elementsLocking mechanismSemi-trailer

The invention relates to a hoisting locking mechanism and a lifting appliance of a highway-railway combined transportation van semitrailer. The locking mechanism comprises container corner fittings, cross beams, tension braces, inclined struts, box iron tension diagonals and cross beam diagonal members. The lifting appliance is a combined type universal lifting appliance which is formed by combining two different specifications of lifting appliances and can be rapidly mounted or demounted and includes the 40-foot main lifting appliance and the 45-foot universal lifting appliance. The hoistinglocking mechanism and the lifting appliance of the highway-railway combined transportation van semitrailer have the advantages and effects that in highway-railway combined transportation process, thevan semitrailer can be directly hoisted into a wagon; the lifting appliance can lift the van semitrailer and can also lift a 45-foot container, and the application range is wider; and an existing universal gantry crane is used for being connected with the van semitrailer during hoisting, the structure is simple, the lifting operation is safer, rapider and more efficient and universal.

Owner:山西聚鑫顺科技有限公司

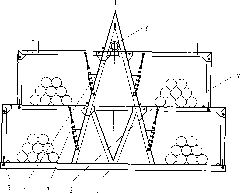

Section storage rack

InactiveCN101823612ALight and strong structureStrong pressure capacityStorage devicesAir springEngineering

The invention discloses a section storage rack. More than two single storage racks are connected in series through a connecting pipe (4) to form a storage rack set; each single storage rack consists of an A-shaped main support frame (1), a space layer supporting beam (2), a supporting foot (7) of the space layer supporting beam (2), a return air spring (3), a connecting buckle (5) and a connecting sleeve (6) positioned on the upper part of the A-shaped main support frame, and the components are arranged in a plurality of layers; one end of the space layer supporting beam (2) is movably connected with the A-shaped main support frame (1), and the other end of the space layer supporting beam (2) is movably connected with one end of the supporting foot (7); the other end of the supporting foot (7) can be fixed to or separated from the supporting beam at the lower layer of the supporting foot (7) through the connecting buckle (5); and the return air spring is arranged between each space layer supporting beam and the A-shaped main support frame. The section storage rack with the structure achieves the purposes of making the stored material get in the rack first and making the stored material get out of the rack first and ensuring small occupation of land, tidy stacking, convenient management of stacking and taking of the different materials and safe and high-efficiency hoisting operation.

Owner:龙工(福建)液压有限公司

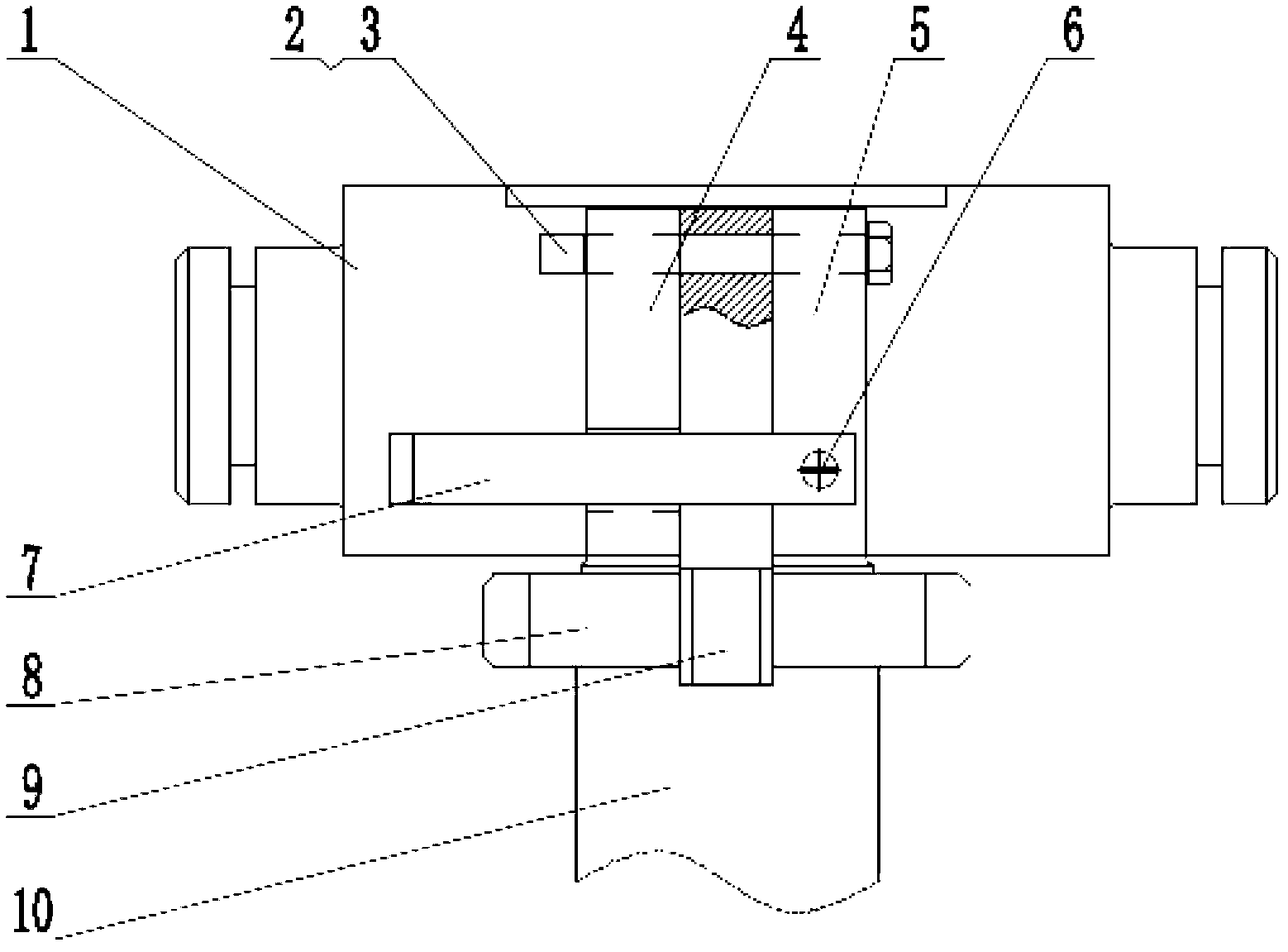

Flange hoisting device

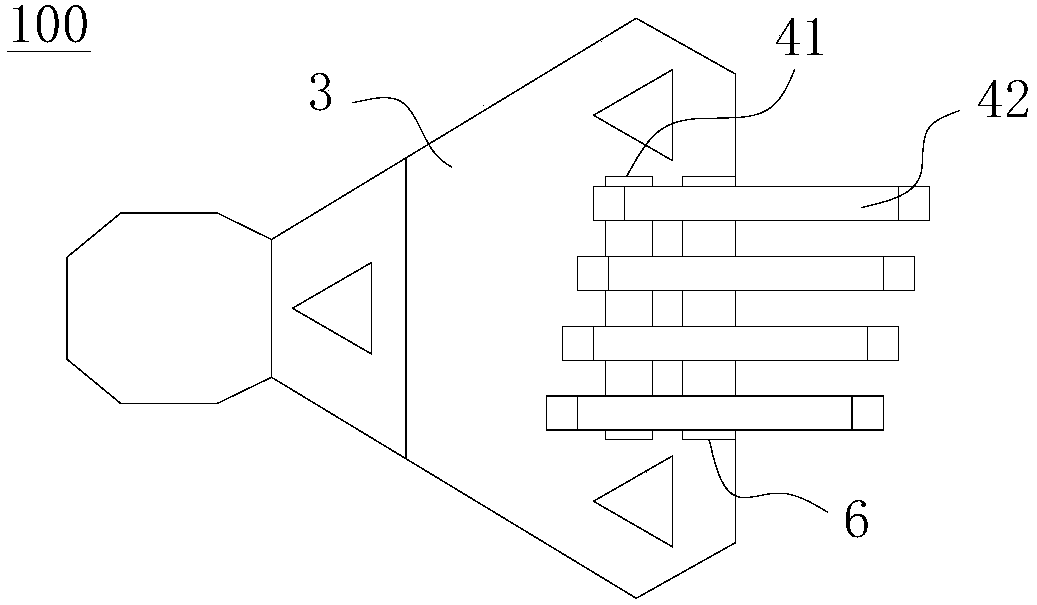

InactiveCN103964297ASimple structural designSafe and reliable lifting operationLoad-engaging elementsEngineeringScrew cap

The invention provides a flange hoisting device, which comprises two hoisting lug plates and a hoisting point pore plate, wherein the plate surfaces of the two hoisting lug plates and the hoisting point pore plate are arranged in parallel and are assembled together through a connecting shaft; the two hoisting lug plates are positioned below two sides of the hoisting point pore plate respectively; the hoisting point pore plate keeps the same distances away from the two hoisting lug plates through a spacing short pipe inserted into the connecting shaft; the two ends of the connecting shaft are inserted into the outer sides of the two hoisting lug plates respectively and are fastened through screw caps to prevent the hoisting lug plates from falling off. The flange hoisting device is simple and reasonable in structure and high in practicability, and flange hoisting operation is safe, convenient and efficient.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Lifting hook anti-rotation positioning apparatus

InactiveCN103224195APrevent rotationFlexible rotationLoad-engaging elementsIndustrial engineeringEngineering

The invention discloses a lifting hook anti-rotation positioning apparatus, which comprises a cross beam, a pin shaft, a pin, a hook stopping shape plate, a rectangular flat plate, a bolt with slots, a J-shaped baffle, a locking sheet with a keyway, an L-shaped plate, and a lifting hook body, wherein a locking washer with a keyway is arranged on the lifting hook, and the L-shaped plate and the J-shaped baffle are welded on the cross beam so as to indirectly and integratedly fix the lifting hook and the cross beam. The lifting hook anti-rotation positioning apparatus has a characteristic of compact and reasonable structure, wherein the crane lifting hook can be well prevented from rotation during an operation process, and can flexible rotate when the positioning apparatus is uplifted, and the lifted object positioning is easily achieved with the apparatus so as to provide safety and reliability for the whole lifting operation.

Owner:HENAN HUABEI ELEVATORING HOOK

Electric tensioning mechanism for traction steel wire rope of trolley of tower crane

The invention discloses an electric tensioning mechanism for a traction steel wire rope of a trolley of a tower crane. The electric tensioning mechanism comprises a motor, a planetary gear reducer, aratchet wheel, a detent, a tension spring and a mounting seat and is characterized in that the output end of the motor is connected with the input end of the planetary gear reducer, the planetary gearreducer is connected with the mounting seat, the output end of the planetary gear reducer is connected with the ratchet wheel, and the motor drives the ratchet wheel to rotate through the planetary gear reducer; the detent is connected with the mounting seat, the tension spring is assembled between the detent and the mounting seat, one end of the tension spring is connected with the detent, and the other end of the tension spring is connected with the mounting seat; and the detent is cut into a tooth groove of the ratchet wheel through the pulling force effect of the tension spring. The electric tensioning mechanism has the characteristics of being convenient to operate, stable, quick, safe and reliable; the motor drives the ratchet wheel to rotate through the planetary gear reducer so asto wind the traction steel wire rope, thus the traction steel wire rope can be tensioned quickly and effectively, it is ensured that the traction steel wire rope has the enough tension, and thus thetower crane is safer during hoisting operation, and more precise in positioning.

Owner:GUANGXI CONSTR ENG GROUP CONSTR MACHINERY MFG

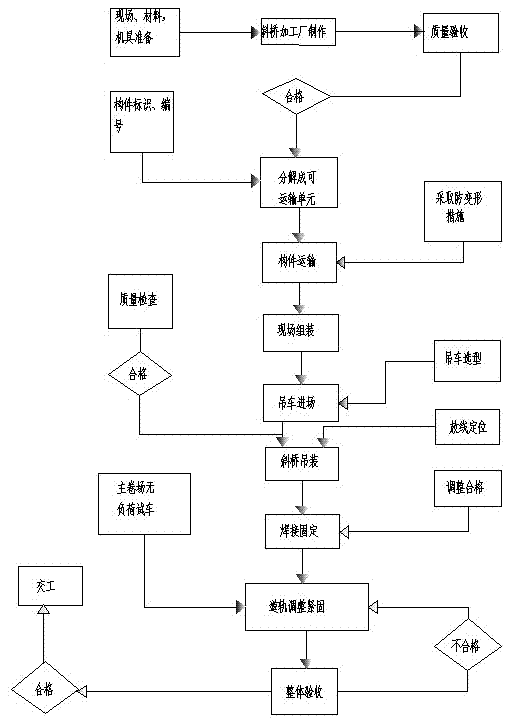

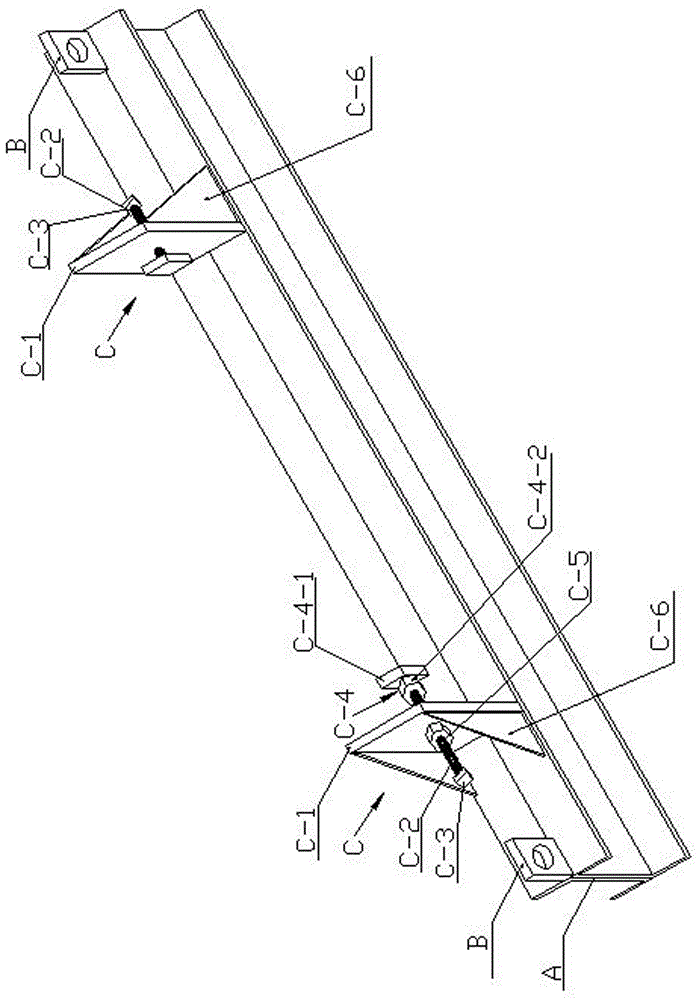

Manufacture and installation methods for shaft furnace feeding skew bridge

InactiveCN103159111ASolve the difficulties of production and installationSafe and reliable lifting operationBuilding liftsTerra firmaShaft furnace

The invention relates to manufacture and installation methods for a shaft furnace feeding skew bridge. The manufacture and installation methods for the shaft furnace feeding skew bridge comprise skew bridge manufacturing, skew bridge transportation, field assembly, hoisting equipment and sling calculating and selecting, and skew bridge suspension setting. The selection of skew bridge hoisting steel wire rope of hoisting equipment and sling calculating and selecting is confirmed by calculating the breaking force of the steel wire rope. The computational formula is as follows: sling tensile force S=component weight / sling number / sine of included angle between sling and horizontal plane, safety coefficient K=8, S<= breaking force of steel wire rope P / safety coefficient K, and confirming the specifications of the steel wire rope by looking up in a manual. According to the manufacture and installation methods for the shaft furnace feeding skew bridge, a construction organization can solve the manufacture and installation difficulties of a skew bridge and safely and fast complete hoisting operation, and a solid foundation is laid for the subsequent manufacture and installation of a shaft furnace structure and smooth production.

Owner:CHINA 22MCC GROUP CORP

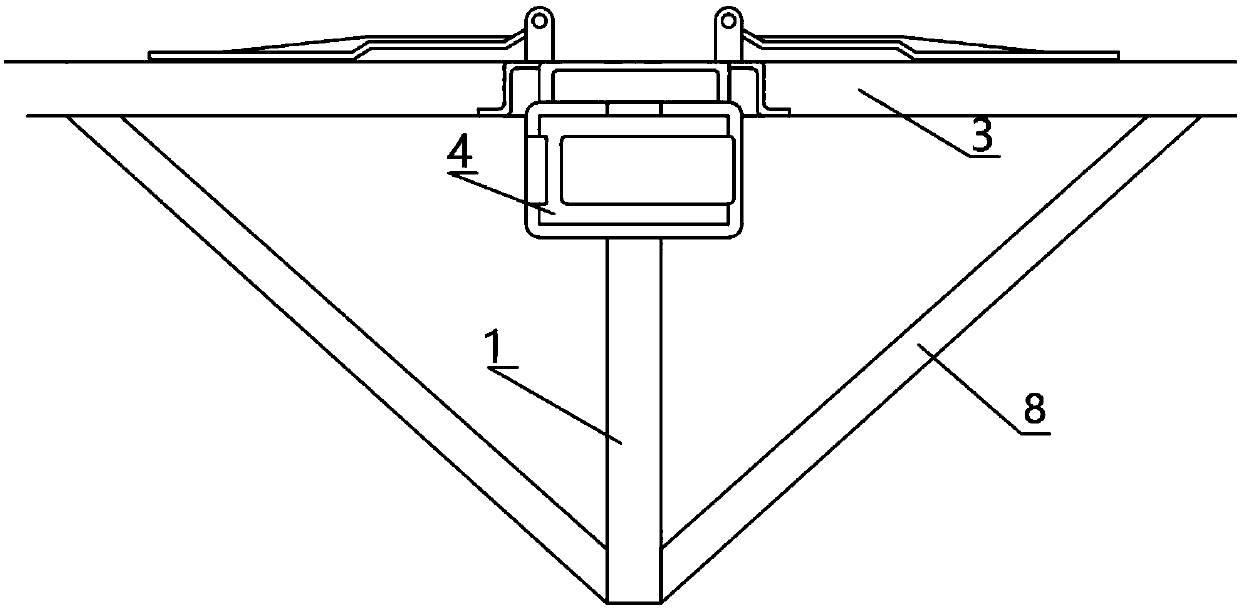

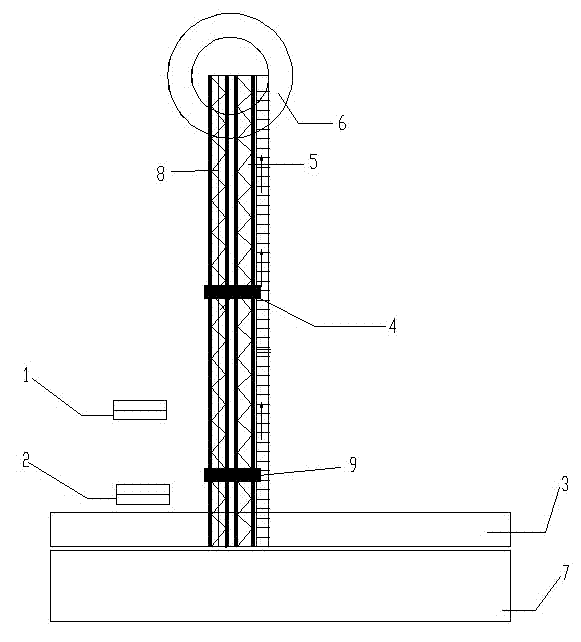

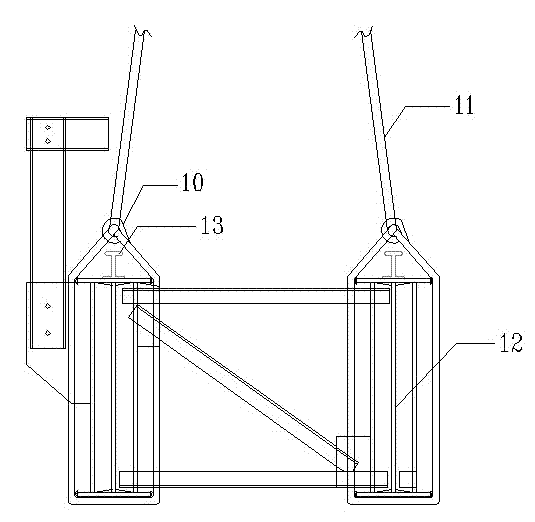

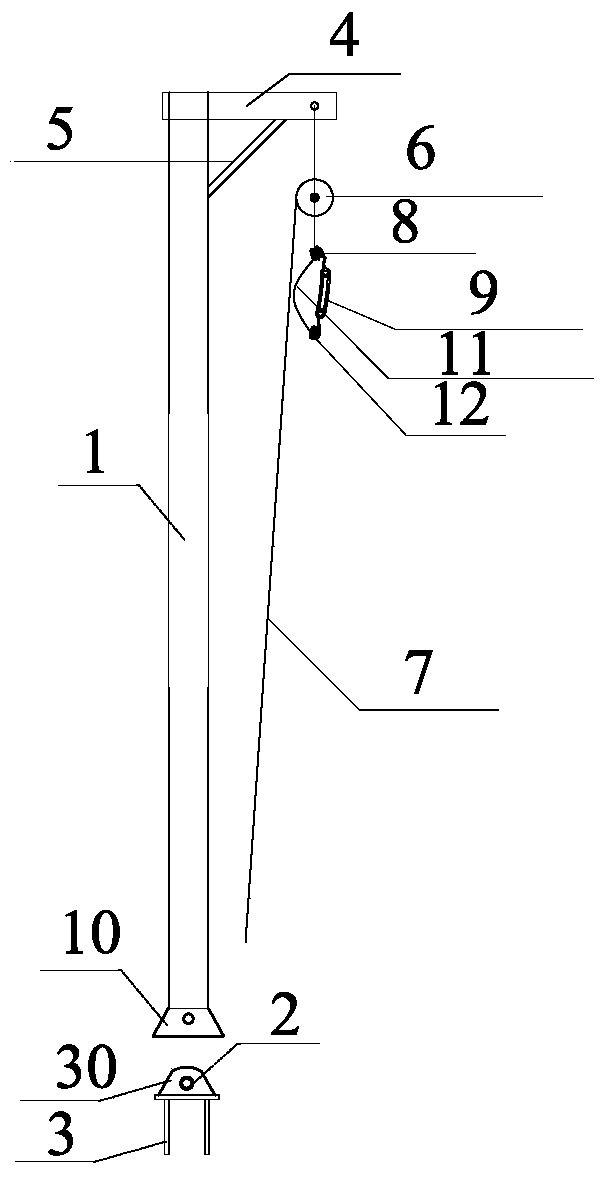

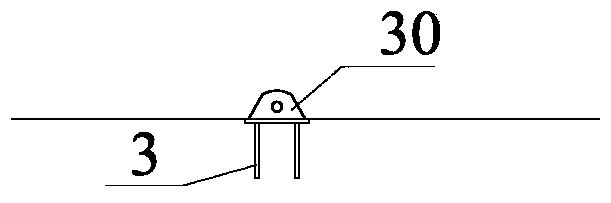

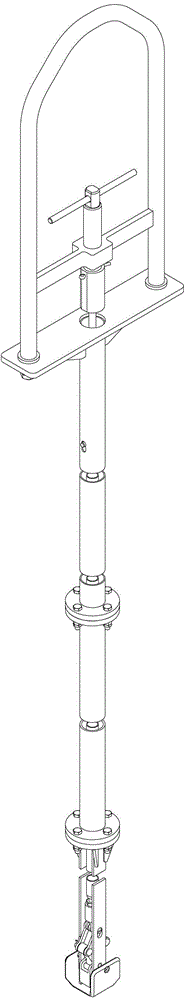

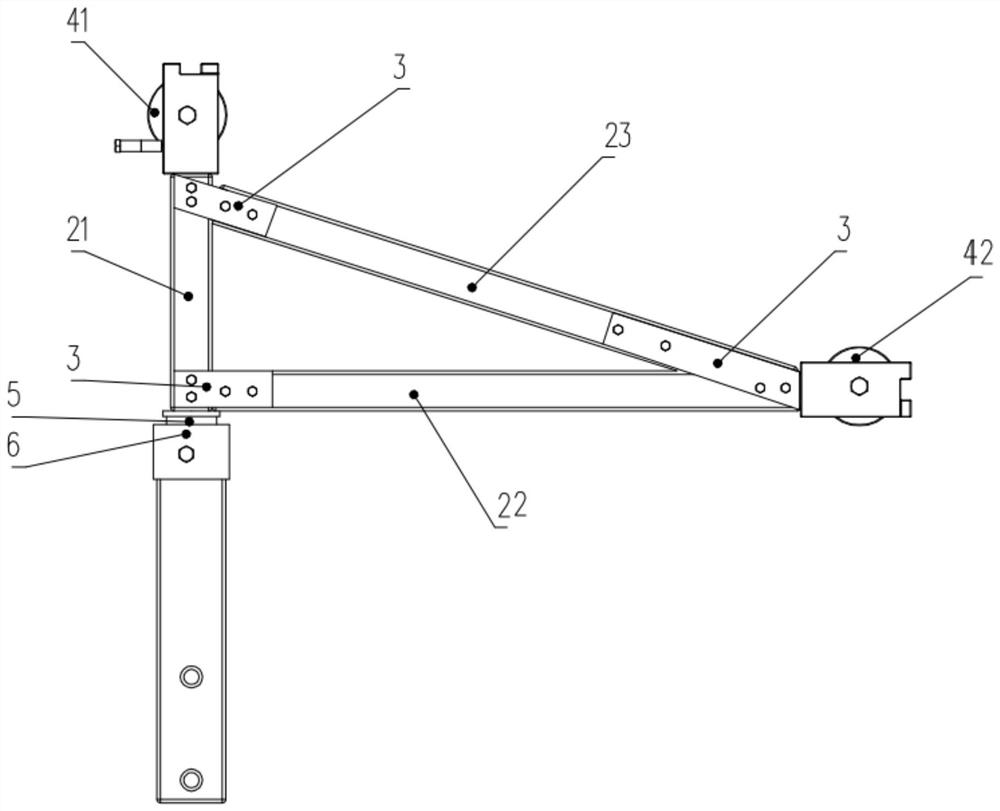

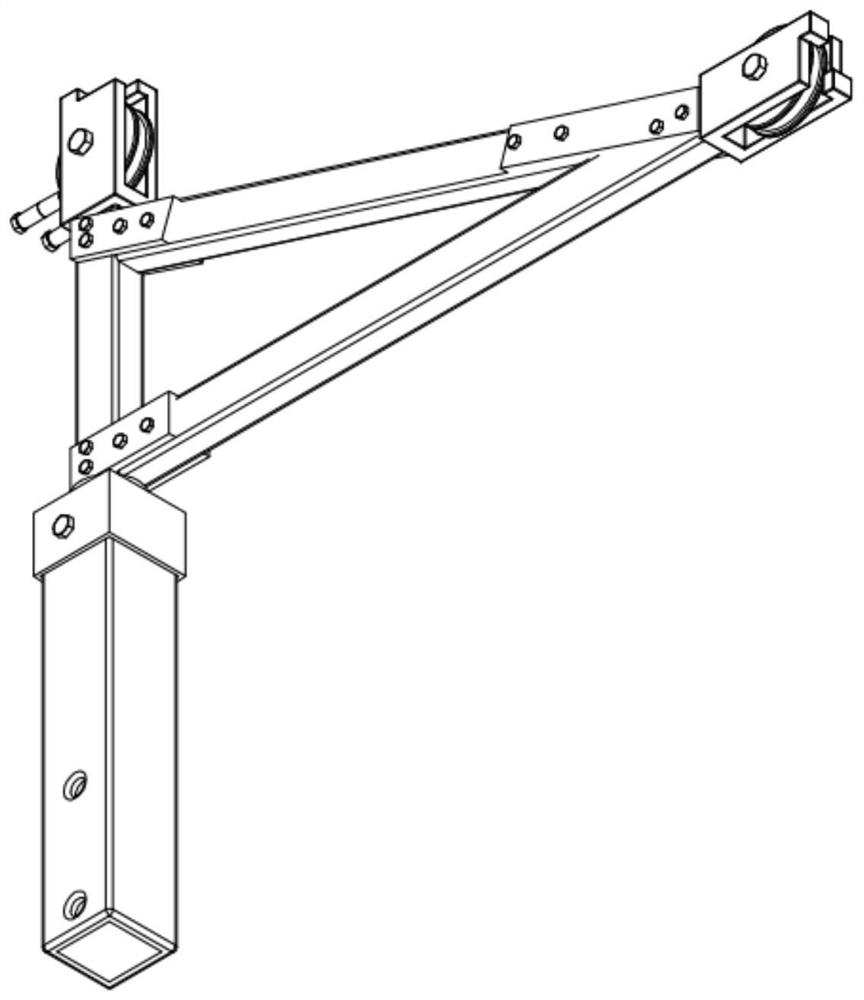

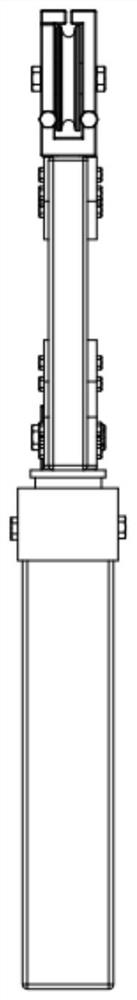

A movable independent pole hoisting device and its hoisting method

ActiveCN105417422BSafe and reliable lifting operationReliable lifting operationGearing elementsTower craneIndustrial engineering

The invention provides a movable independent derrick mast lifting device and a lifting method of the lifting device. The movable independent derrick mast lifting device comprises a derrick mast stand column, a pin shaft and an embedded part. A base is arranged at the bottom of the derrick mast stand column. A pin shaft hole is formed in the base. An installation plate is arranged at the position, corresponding to the base, of the top end of the embedded part. A pin shaft hole corresponding to the pin shaft hole in the base is formed in the installation plate. The derrick mast stand column is installed on the embedded part in the manner that the pin shaft penetrates the pin shaft hole in the base and the pin shaft hole in the installation plate. By means of the structure, the performance that the lifting efficiency is high, manufacturing cost is low, demounting is convenient and use is flexible is achieved, and in addition, safe and reliable lifting work can be achieved on components within 10 tons in areas which have hidden environments or have small and narrow space or cannot be covered by a tower crane.

Owner:CHINA CONSTR SCI & IND CORP LTD

Inversely assembling process for standing stay wire V-type tower

The invention relates to an inversely assembling process for a standing stay wire V-type tower. The process comprises the following steps: assembling a standing door type rack, assembling the head part of the stay wire V-type tower and mounting point rope systems, inversely assembling the stay wire V-type tower, and placing the stay wire V-type tower in place. According to the process, the head part of the stay wire V-type tower is lifted to a certain height above the ground through the door type rack first, then a lower tower segment is assembled below the head part of the stay wire V-type tower, after that, the head part of the stay wire V-type tower continues to be lifted, so as to continue to assemble a second lower tower segment, and the assembling continues until tower legs are assembled. In the process, the door type rack is adopted to inversely assemble the standing stay wire V-type tower in a decomposing manner, so that the load on an appliance is greatly reduced and the hoisting operation is safe and reliable; and the process is suitable for inversely assembling a large-scale stay wire V-type tower and is also suitable for occasions unsuitable to adopt large-scale cranes for operations. The process doesn't need a large-scale crane and is little limited by transportation, and a door type rack hoist system formed by combining machines and tools used frequently for daily construction can replace the large-scale crane to fulfill a task.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

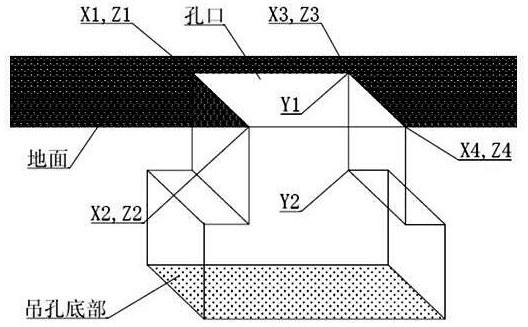

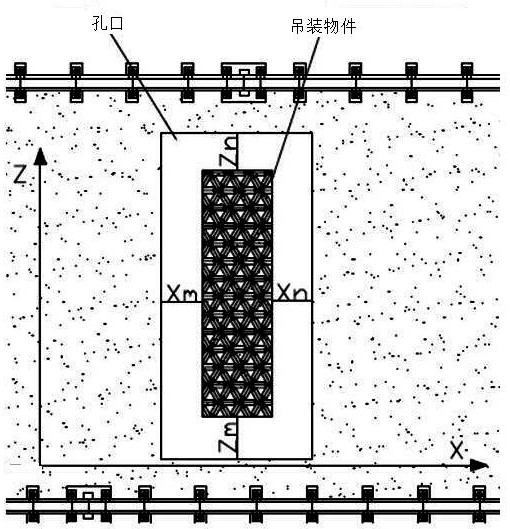

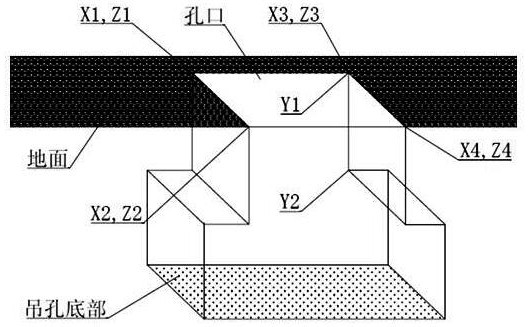

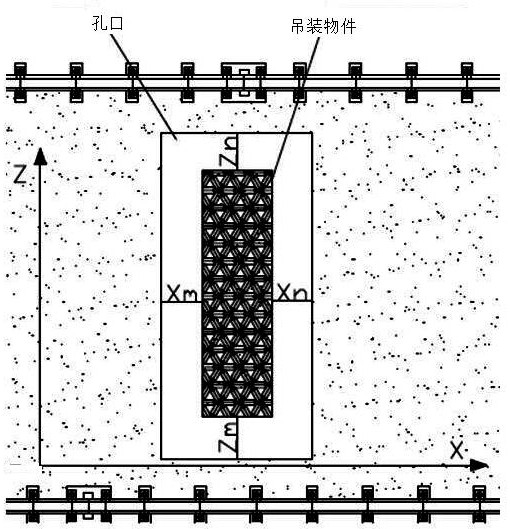

A method of crane operation route planning

ActiveCN112897346BEnsure safe circumvention of obstaclesImprove space efficiencySafety gearHuman–machine interfaceControl engineering

The invention discloses a crane operation route planning method, which belongs to the technical field of crane electrical control, and is characterized in that it comprises the following steps: a. establishing a three-dimensional coordinate system; The space is set in the PLC controller according to the three-dimensional coordinate system, and the external dimensions of the pre-hoisted maximum size object are set in the PLC controller according to the three-dimensional coordinate system; c. Write the PLC program; d. According to the large size detected by the PLC controller Car and trolley walking real-time coordinate value comparison judges whether the hoisting object is in the safe area in the opening; e, calculate the distance between the hook and the wire rope position and the edge of the opening through formula 6-9. The present invention can ensure that the crane safely circumvents obstacles in the operating range, and at the same time releases a larger allowable operating area for the crane, thereby greatly improving the working space and working efficiency.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

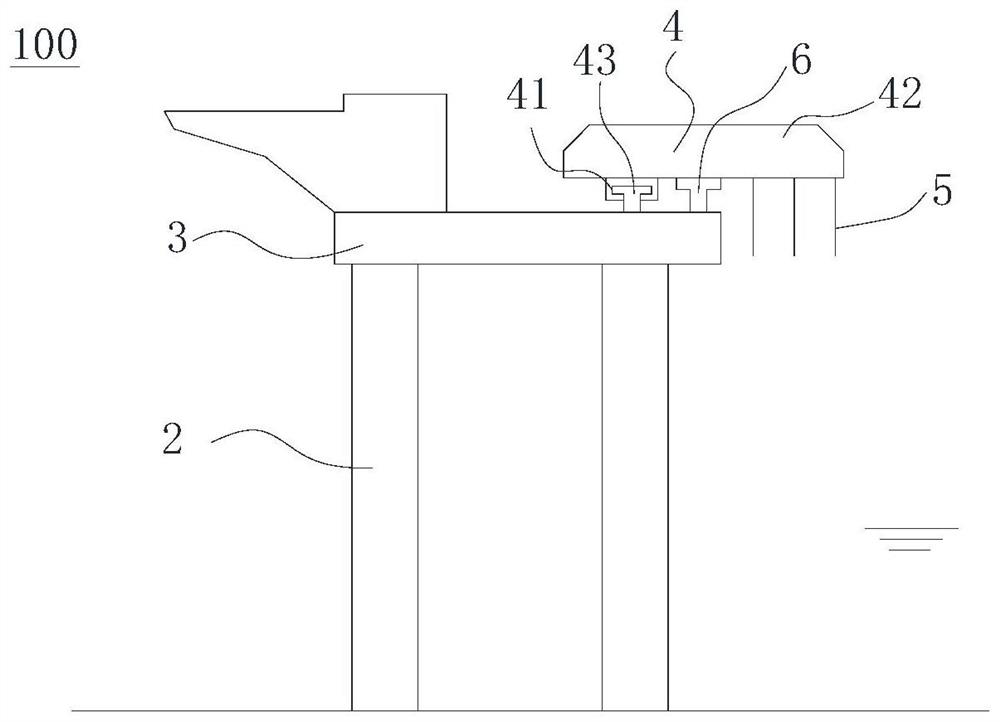

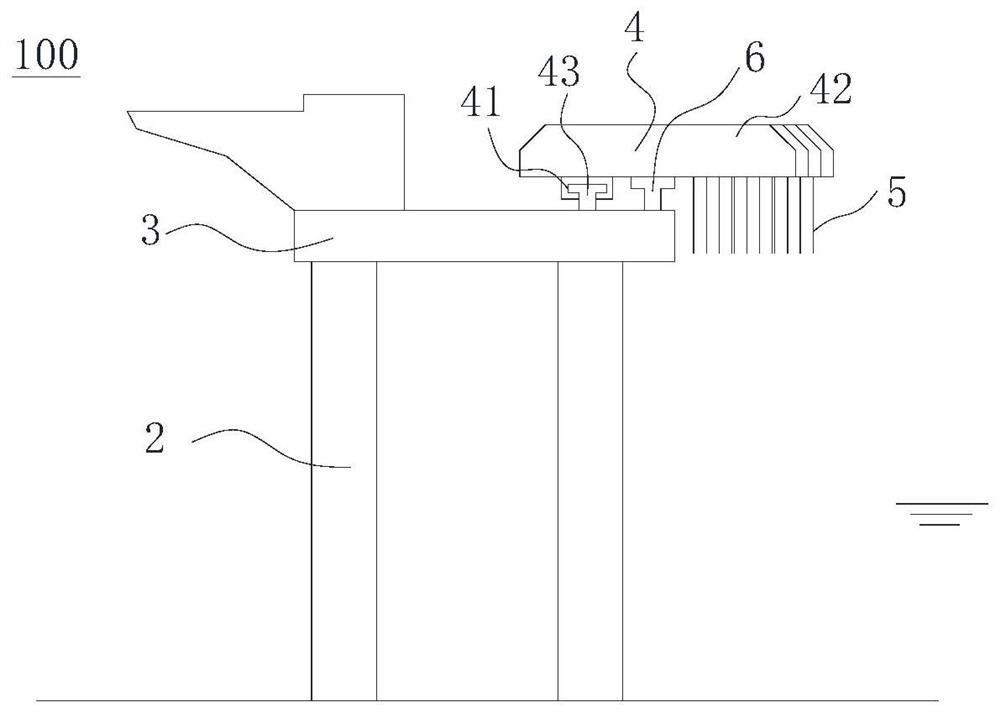

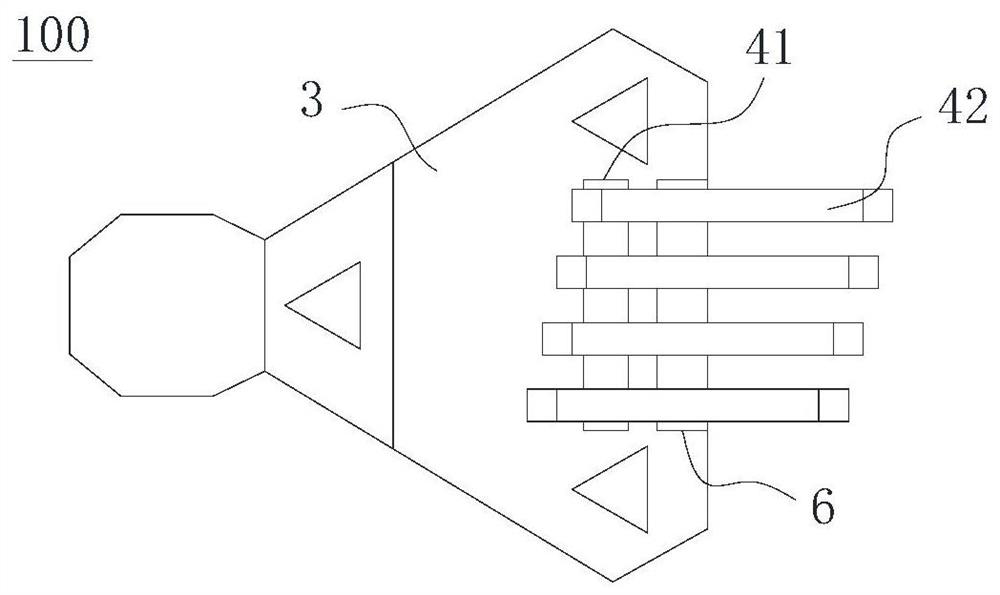

Hoisting device and hoisting method

PendingCN113071984AIncrease tonnageImprove securityLoad-engaging elementsControl engineeringStructural engineering

The invention discloses a hoisting device and a hoisting method. The hoisting device comprises a body, a first hoisting lug group and a second hoisting lug group, and the first hoisting lug group is arranged on the upper end surface of the body and is used for being matched with hoisting hooks of more than two bridge cranes on a hoisting station; and the second hoisting lug group is arranged on the lower end face of the body and used for being matched with a hoisting point of a to-be-hoisted part so that the to-be-hoisted part can be vertically hoisted. The hoisting device can enable more than two bridge cranes to participate in hoisting at the same time, so that the hoisting tonnage of the cranes is increased; and in addition, the function of transferring the bridge cranes and the to-be-hoisted part is achieved, the hoisting hooks with the fixed positions of the bridge cranes is converted into a hoisting point matched with the to-be-hoisted part, the problem that the lifting point position of the to-be-hoisted part cannot meet the hoisting standard of two or more cranes is solved, under the limited hoisting condition on a hoisting station, the reliable and safe hoisting operation on large parts is completed, the application range of the bridge cranes in a construction site or a factory is enlarged, and the hoisting time is saved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Special tool for hoisting of coal feeder

The invention discloses a special tool for hoisting of a coal feeder. The special tool comprises a trimmer (A) and is characterized in that lifting lugs (B) are welded at the upper parts of two ends of the trimmer (A), and two clamping devices (C) are fixedly arranged on the upper surface of the middle part of the trimmer (A); the distance between the two clamping devices (C) is matched with the width of the coal feeder. Compared with the prior art, the special tool is convenient to use and simple to operate; a flexible-connection hoisting process in the prior art is improved as rigid-connection hoisting, so that hoisting operation is relatively safe, the working efficiency is doubled, and the special tool has favorable popularization prospect.

Owner:中煤第九十二工程有限公司

Self-elevating platform and method for lifting jacket by using self-elevating platform

The invention provides a self-elevating platform and a method for lifting a jacket by using the self-elevating platform. The self-elevating platform comprises a platform main body, an elevating deviceand a sliding device, wherein the elevating device is used for adjusting the vertical height of the platform main body. The sliding device is arranged on a deck of the platform main body and can moveon the deck. A part of the sliding device can extend out of the edge of the deck outwards and form a jib. The lower part of the extending-out part is connected with a hanger through a cable so as tobe connected with a to-be-lifted object. The self-elevating platform is simple in structure and low in manufacturing cost, and hanging point positioning can be effectively and accurately conducted through arrangement of the sliding device; and meanwhile, because the self-elevating platform is at seat bottom column pile, compared with a traditional floating crane, the self-elevating platform does not move along with the wave during lifting of the jacket, movement and sloshing of a hull due to the wave flow are avoided, and especially, collision between a lifted upper module and the jacket due to the fact that the hull moves along with the waves is avoided, so that lifting operation is safer and more reliable.

Owner:YANTAI RAFFLES SHIPYARD +2

Hoisting method of machine set generator stator and special mechanism thereof

InactiveCN101624164BImprove bending abilityOptimize layoutTravelling cranesWinding mechanismsHoopingEngineering

The invention relates to a hoisting method of a machine set generator stator and a special mechanism thereof, which is characterized in that an assistant beam frame structure (2) is in bridge joint on two travelling crane rails (1-1) of two 80-ton travelling crane mechanisms (1) in a main factory, and a hydraulic pressure hoisting device (3) is arranged on the assistant beam frame structure (2); thus, the travelling crane rails change from one-point stress into multi-point stress or region stress so as to improve the anti-bending ability of the travelling crane rails. The invention dispenses with extra hanger frames, a girder of the travelling crane dispenses with re-hooping, and a dolly of the travelling crane dispenses with dissembling and is suitable for installation and stator maintaining and hoisting operations of 300MW-firepower machine set generator stators in China; the invention has the benefits of simple arrangement, short operation time, no need of deferred installation of the main factory structure and quick and safe hoisting operation.

Owner:GUANGDONG POWER ENG

Jacket hoisting device and method for hoisting jacket with the device

ActiveCN108071101BSimple structureLow costArtificial islandsUnderwater structuresMechanical engineeringHoist device

The invention provides a self-elevating platform and a method for lifting a jacket by using the self-elevating platform. The self-elevating platform comprises a platform main body, an elevating deviceand a sliding device, wherein the elevating device is used for adjusting the vertical height of the platform main body. The sliding device is arranged on a deck of the platform main body and can moveon the deck. A part of the sliding device can extend out of the edge of the deck outwards and form a jib. The lower part of the extending-out part is connected with a hanger through a cable so as tobe connected with a to-be-lifted object. The self-elevating platform is simple in structure and low in manufacturing cost, and hanging point positioning can be effectively and accurately conducted through arrangement of the sliding device; and meanwhile, because the self-elevating platform is at seat bottom column pile, compared with a traditional floating crane, the self-elevating platform does not move along with the wave during lifting of the jacket, movement and sloshing of a hull due to the wave flow are avoided, and especially, collision between a lifted upper module and the jacket due to the fact that the hull moves along with the waves is avoided, so that lifting operation is safer and more reliable.

Owner:YANTAI RAFFLES SHIPYARD +2

Crane running route planning method

ActiveCN112897346AEnsure safe circumvention of obstaclesImprove space efficiencySafety gearHuman–machine interfaceControl engineering

The invention discloses a crane running route planning method, and belongs to the technical field of crane electrical control. The crane running route planning method is characterized by comprising the following steps that a, a three-dimensional coordinate system is established; b, through a human-computer interface, the space, allowing passage of a hoisted object, of each hole opening is arranged in a PLC according to the three-dimensional coordinate system, and the boundary dimension of the to-be-hoisted object with the maximum size is arranged in the PLC according to the three-dimensional coordinate system; c, a PLC program is compiled; d, according to the walking real-time coordinate values, detected by the PLC, of a cart and a trolley, whether the hoisted objects are in safe areas in the hole openings or not is judged through comparison; and e, the distances from the positions of lifting hooks and steel wire ropes to the edges of the hole openings are calculated through formulas 6-9. According to the method, it can be ensured that a crane safely bypasses obstacles in a running interval, a larger allowable running area is released to the crane, and the operation space and the operation efficiency are greatly improved.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

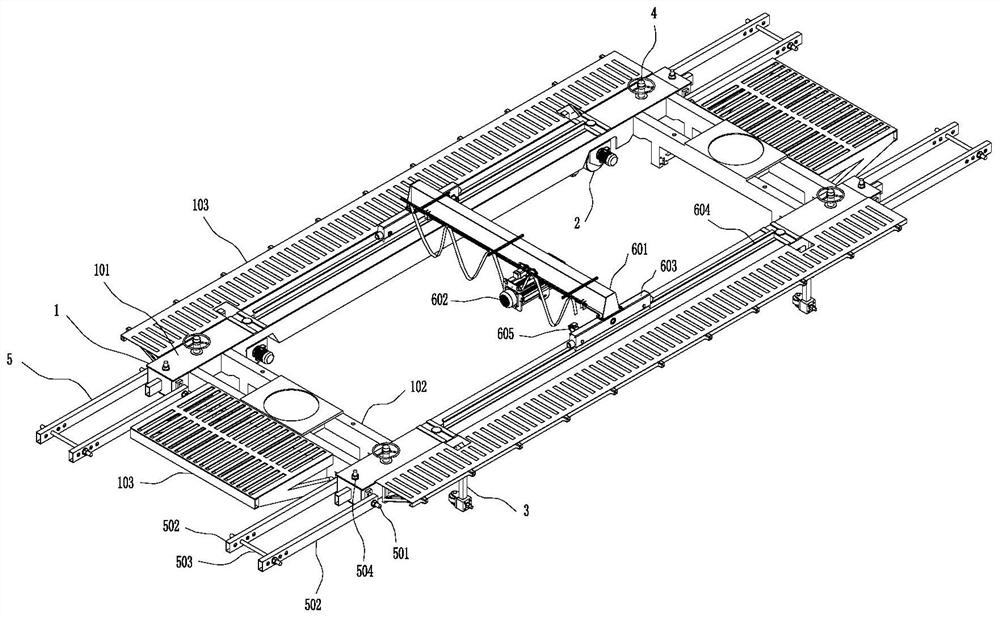

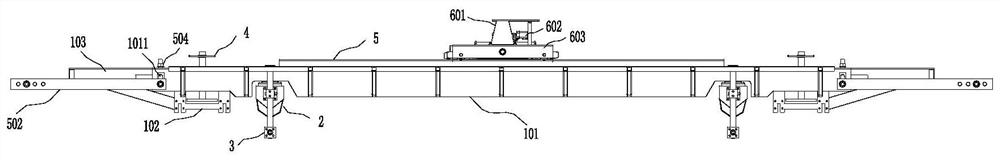

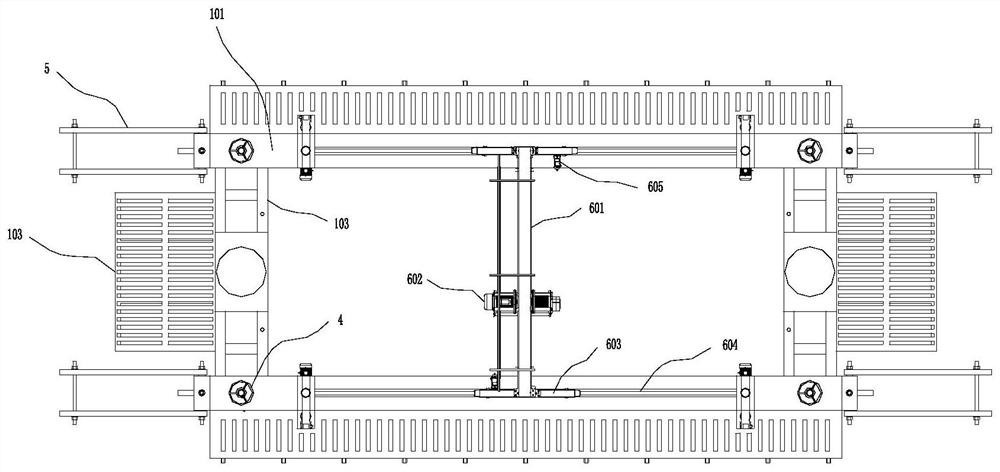

PC track beam evacuation passage construction operation vehicle

PendingCN112127283ASmall footprintSafe and reliable lifting operationRailway tracksTravelling cranesVehicle frameTrackway

The invention discloses a PC track beam evacuation passage construction operation vehicle which comprises a vehicle frame, a walking mechanism, a guide mechanism and a hoisting assembly. The vehicle frame comprises a longitudinal beam and a cross beam, and the PC track beam evacuation passage construction operation vehicle is characterized by further comprising a bearing force conversion assemblyused for jacking the operation vehicle from a track beam to enable the walking mechanism to be separated from the track beam and supporting the operation vehicle on the track beam, and a parking locking assembly which is used for enabling the operation vehicle to be detachably connected and fixed to the track beam. The operation vehicle can automatically walk on the installed track beam, can alsobe suitable for a curve track beam, can stably and safely hoist and construct the steel cross beam and the steel longitudinal beam as a whole, saves time and labor, and is high in construction efficiency.

Owner:CCFEB CIVIL ENG +2

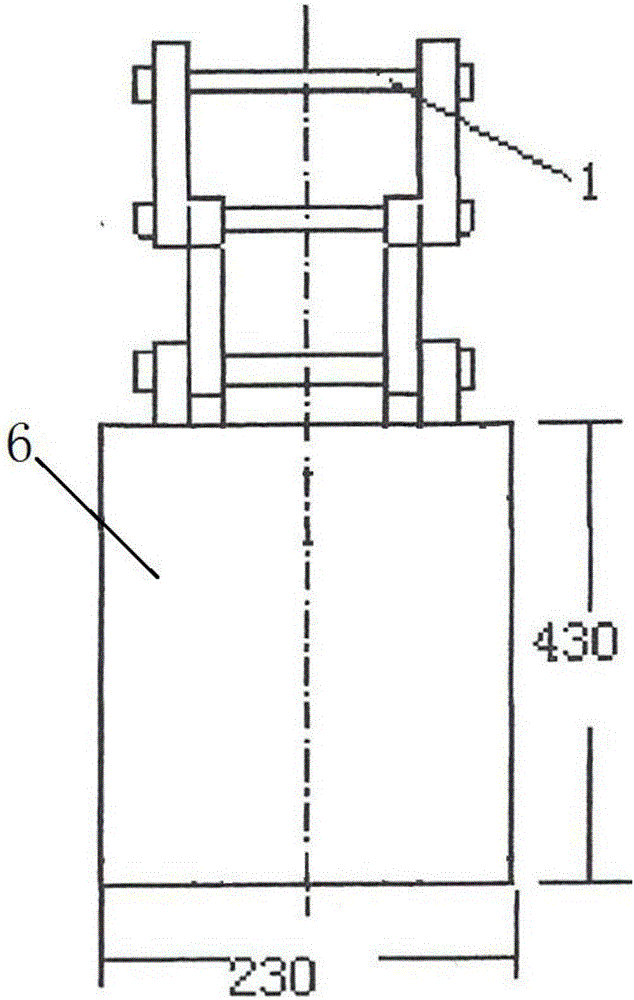

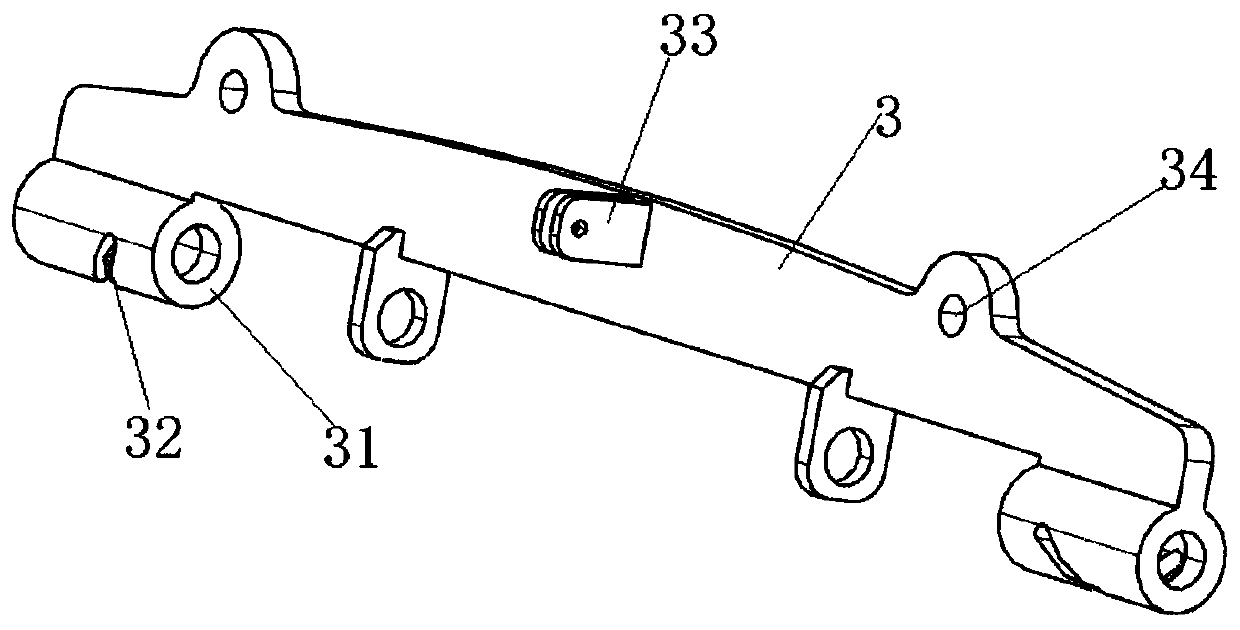

Special jig for hoisting of crushing teeth of crushing machine

InactiveCN105967053ASimple structureSafe and reliable lifting operationLoad-engaging elementsSpecial designEngineering

The invention relates to a special jig for hoisting of crushing teeth of a crushing machine. The special jig comprises a hoisting rack (1), two connecting rods (2) and two symmetrically arranged hinge rods (3), wherein the top ends of the two connecting rods are hinged to the hoisting rack, the bottoms of the connecting rods are hinged to the top ends of the hinge rods, the two hinge rods are hinged by a hinge pin (4), and the bottom ends of the two hinge rods are bent inwards to form a pair of hooking pliers (5). Reinforcing plates (6) are fixedly arranged at the outer sides of the two hinge rods. The height of the reinforcing plates is 430mm, and the width is 230mm. Reinforcing ribs (7) are fixedly arranged at the inner sides of the two hinge rods. The special jig is simple in structure, safe and reliable in hoisting operation, and high in hoisting efficiency, and the working efficiency of operation with the special jig is improved by more than 200% in comparison with the hoisting working efficiency of manpower banding, thus having high practical utilization value.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

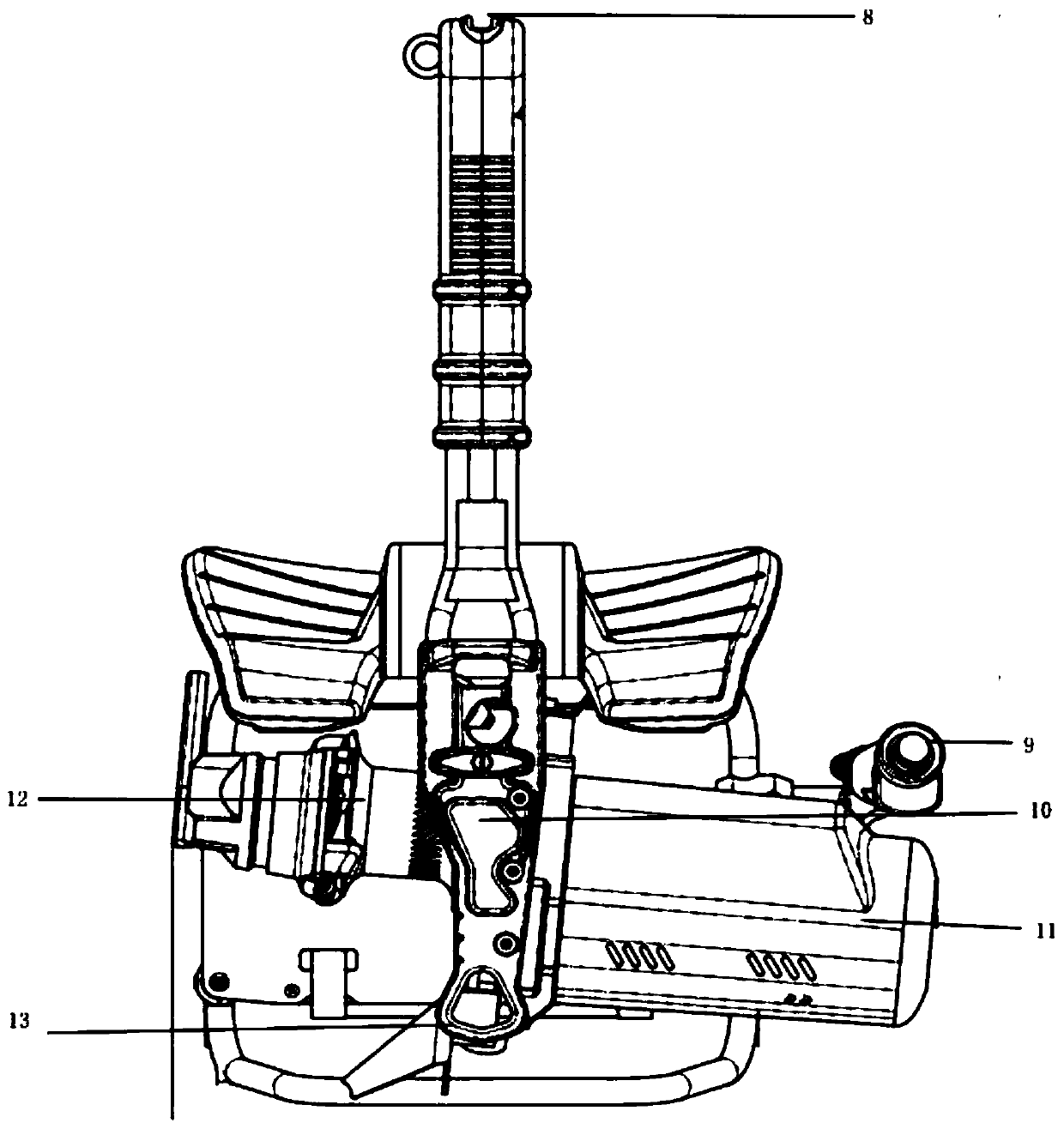

Electric chairlift

PendingCN110078002ASafe and reliable lifting operationStable and smooth lifting operationSafety devices for lifting equipmentsElectricityEngineering

The invention belongs to the technical field of building decoration mechanical equipment, and relates to an electric chairlift. The electric chairlift comprises a framework. A motor and a battery usedfor supplying power to the motor are mounted on the framework. The output end of the motor is connected with a speed reducer, and the output end of the speed reducer is connected with a rope gripper.A chair is clamped at the top of the framework. A vertical rod is further fixedly connected to the chair. A lifting ring is arranged at the top of the vertical rod. The vertical rod is of a hollow structure. A rope inlet at the top of the vertical rod communicates with a hollow inner hole of the vertical rod. An emergency stop switch and an ascending and descending switch are further arranged onthe framework and are both electrically connected with the motor. By means of the chairlift, spidermen can freely ascend and descend in the work process, the working efficiency is effectively improved, and meanwhile the risk of aloft work is reduced.

Owner:SUZHOU ASCENDER MACHINERY CO LTD

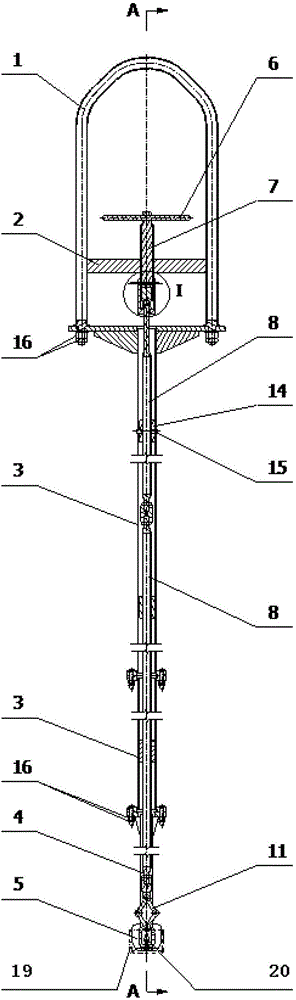

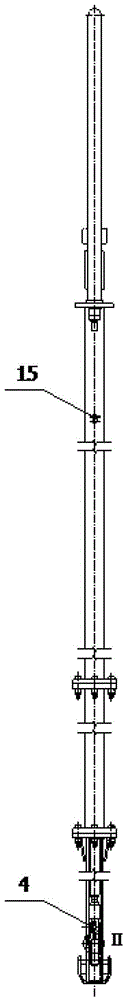

Novel long rod sling

ActiveCN102795538BSafe and reliable lifting operationGuaranteed thicknessLoad-engaging elementsEngineeringMechanical engineering

Owner:CHINA NUCLEAR POWER ENG CO LTD

Rotary right-angle hoisting device suitable for insulating bucket arm vehicle

The invention provides a rotary right-angle hoisting device suitable for an insulating bucket arm vehicle. The rotary right-angle hoisting device comprises a stand column, a main shaft, a vertical suspension arm, a horizontal suspension arm and an inclined suspension arm. The main shaft is arranged at the top of the stand column and can rotate around the axis of the stand column. The bottom of thevertical suspension arm is connected with the main shaft, and a first pulley is arranged at the top of the vertical suspension arm. One end of the horizontal suspension arm is connected with the bottom of the vertical suspension arm, and a second pulley is arranged at the other end of the horizontal suspension arm. One end of the inclined suspension arm is connected with the top of the vertical suspension arm, and the other end of the inclined suspension arm is connected with the other end of the horizontal suspension arm. According to the rotary right-angle hoisting device suitable for the insulating bucket arm vehicle, a hoisted object can be flexibly, quickly and safely conveyed to a designated position during hoisting.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

A hanger for automatic hook removal

ActiveCN107473075BImprove convenienceImplement automatic connectionLoad-engaging elementsEngineeringMechanical engineering

Owner:NINGBO RUYI JOINT CO LTD

Sheep eye hook device of crane

The invention relates to a sheep eye hook device of a crane, in particular to a hanger used on the crane for grabbing packed cargos, general cargos and other heavy objects, and the sheep eye hook device belongs to the technical field of the hoisting machinery. The hook device is characterized in that yoke plates on both sides are separated by a sleeve and form a hook body through bolts and nuts; a hook is arranged in a cross beam, hoisting nuts are used to compress a bearing installed on the upper part of the hook so as to fix the bearing on the cross beam; the cross beam is installed on the lower part of the hook body, the two ends of the cross beam are clamped by card boards and fixed by bolts. A pulley is installed on the sleeve outside a pulley shaft through a bearing; the sleeve is provided with a support ring; the both ends of the bearing are fixed by a bearing cover plate; the pulley shaft is installed in the middle of the hook body; one end of the pulley shaft is fixed by a shoulder, the other end is fixed by a card board and bolts; and the upper cover of the hook body is fixed by bolts and nuts. The sheep eye hook device has simple, compact and reasonable structure; and by using the hook device, the working intensity of the operating personnel can be lowered, the steel wire rope can be well prevented from sliding outside under an abnormal external force, and the whole hoisting operation can be safe and reliable.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

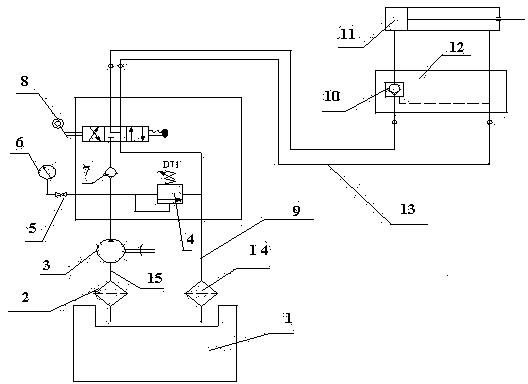

Jacking device of trailer for secondary natural gas fueling station

InactiveCN104229667AImprove securityAvoid cloggingServomotorsLifting devicesControl valvesNatural gas

The invention relates to a jacking device of a trailer for a secondary natural gas fueling station. The jacking device comprises an oil tank, an oil outlet pipe, an oil inlet pipe, a hand-directional valve, an oil absorption filter, an oil pimp and a jacking cylinder. One end of the oil absorption filter is communicated with the oil tank through the oil outlet pipe, and the other end of the oil absorption filter is connected with the oil pump through the oil outlet pipe. The oil pump is connected with the hand-directional valve through a one-way valve arranged on the oil outlet pipe. Two fast-mounted oil pipes are connected to the hand-directional valve. The other end of each fast-mounted oil pipe is connected to a lock-control valve plate which is internally provided with a hydraulic control one-way valve. The jacking cylinder is connected with the fast-mounted oil pipes through the hydraulic control one-way valve. The jacking device is simple, efficient, practical, low in cost and convenient to use.

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

A kind of multi-functional rotating spreader

ActiveCN108557630BSolve balance problemsSimple structureLoad-engaging elementsEngineeringMechanical engineering

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

Positioning device for box girder hoisting steel strand

PendingCN114275658ANo offsetSafe and reliable lifting operationLoad-engaging elementsEngineeringStructural engineering

The invention discloses a positioning device for hoisting steel strands of a box girder, which ensures that the overall position of the steel strands and the relative position of the steel strands do not deviate in the vibrating operation, so that a hoisting shaft can normally penetrate through the steel strands, and the hoisting operation is safely completed. Comprising frame bodies arranged on the two sides of a box girder formwork, each frame body is provided with a first guide groove in the longitudinal direction of the frame body, two cross arms are arranged between the frame bodies, the cross arms are matched with the first guide grooves in the frame bodies to guide the cross arms to move along the first guide grooves, each cross arm is provided with a second guide groove, and the second guide grooves are matched with the first guide grooves. The second guide groove is perpendicular to the first guide groove; two positioning plates are arranged between the two cross arms, and the positioning plates are matched with second guide grooves in the cross arms to guide the positioning plates to move along the second guide grooves; a positioning rod is arranged between the two positioning plates, and a limiting block is arranged on the positioning rod and used for limiting the steel strand.

Owner:新疆交建市政工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com