Jacking device of trailer for secondary natural gas fueling station

A technology for gas filling sub-stations and jacking devices, applied in the direction of lifting devices, fluid pressure actuating devices, servo motors, etc., can solve problems such as few reports, and achieve normal operation, high safety, safe and reliable lifting operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

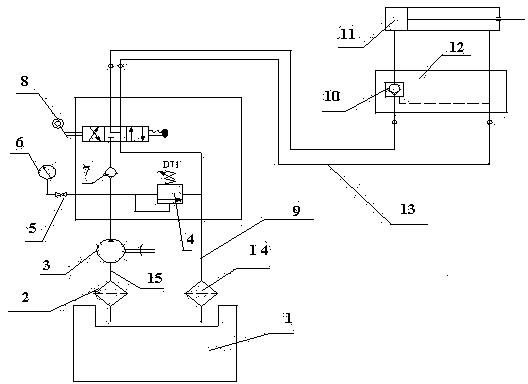

[0016] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

[0017] see figure 1 As shown, the present invention comprises oil tank 1, oil outlet pipe 15, oil inlet pipe 9, manual reversing valve 6, oil suction oil filter 2, oil pump 3, jacking oil cylinder 11 and pressure gauge 6; The range of pressure gauge 6 is 0-40MPa , used to display the pressure of the oil circuit on site, it is controlled by a pressure gauge switch 5, press the pressure gauge switch 5 by hand, the pressure gauge 6 will display the current pressure; lift the slide valve on the pressure gauge switch 5 to cut off the high-pressure liquid oil circuit At the same time, the pressure medium in the oil pipe between the slide valve on the pressure gauge switch 5 and the pressure gauge can be relieved, and part of the oil can flow back to the oil tank 1. The manual reversing valve 8 is connected to the lock control valve plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com