Positioning device for box girder hoisting steel strand

A positioning device, a technology for steel strands, applied in the directions of transportation and packaging, load hanging components, etc., can solve the hidden danger of steel strand breakage, the inability of the lifting tool shaft to pass through the steel strand, and the stress concentration of the steel strand, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

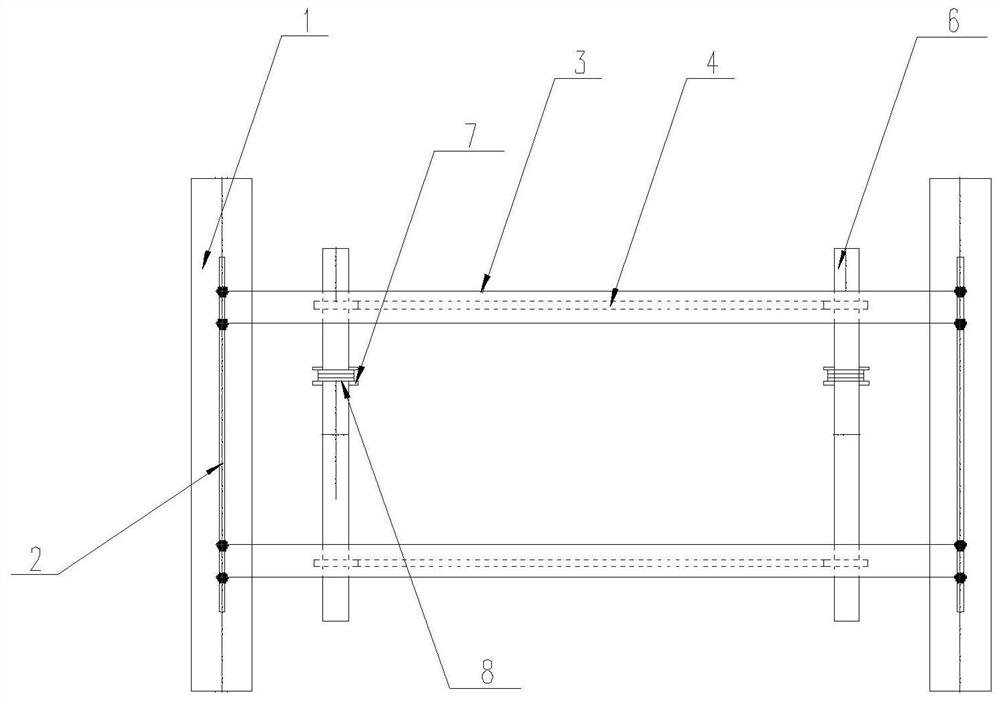

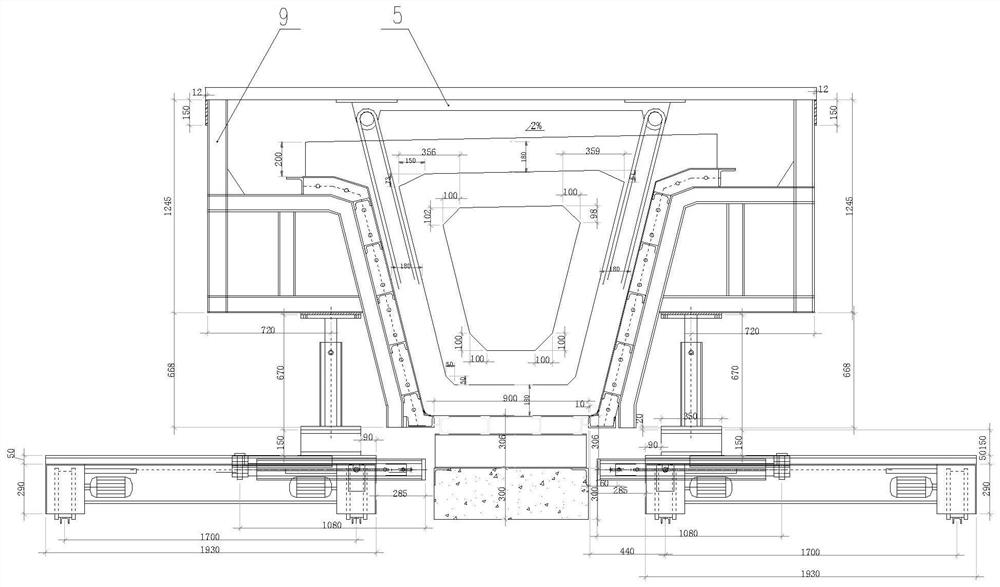

[0018] see figure 1 , figure 2 , is a positioning device used for box girder hoisting steel strands. In the accompanying drawings, 1 is the frame body, 2 is the first guide groove, 3 is the cross arm, 4 is the second guide groove, 5 is the positioning plate, 6 7 is a positioning bar, 7 is a limit block, 8 is a steel strand, and 9 is a box girder formwork.

[0019] A positioning device for hoisting steel strands of a box girder, comprising frame bodies arranged on both sides of the formwork of the box girder, each frame body is respectively provided with a first guide groove along the longitudinal direction of the frame body, and the frame bodies are provided with Two cross-arms, the cross-arms are matched with the first guide grooves on the frame body to form a guide for the cross-arms to move along the first guide grooves, each cross-arm is respectively provided with a second guide groove, and the second guide groove Vertical to the first guide groove; two positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com