Electric tensioning mechanism for traction steel wire rope of trolley of tower crane

A technology for pulling wire ropes and tower cranes, which is applied to cranes and other directions, can solve the problems of safety hazards in tensioning work, long time-consuming, untimely tensioning, etc., and achieve the effects of convenient operation, difficult operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

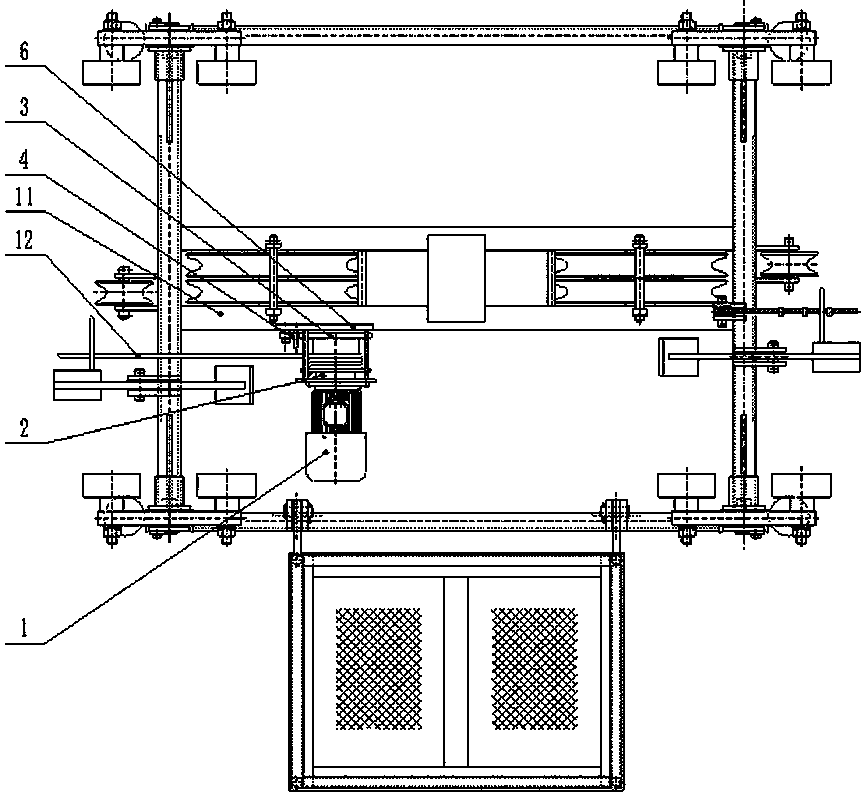

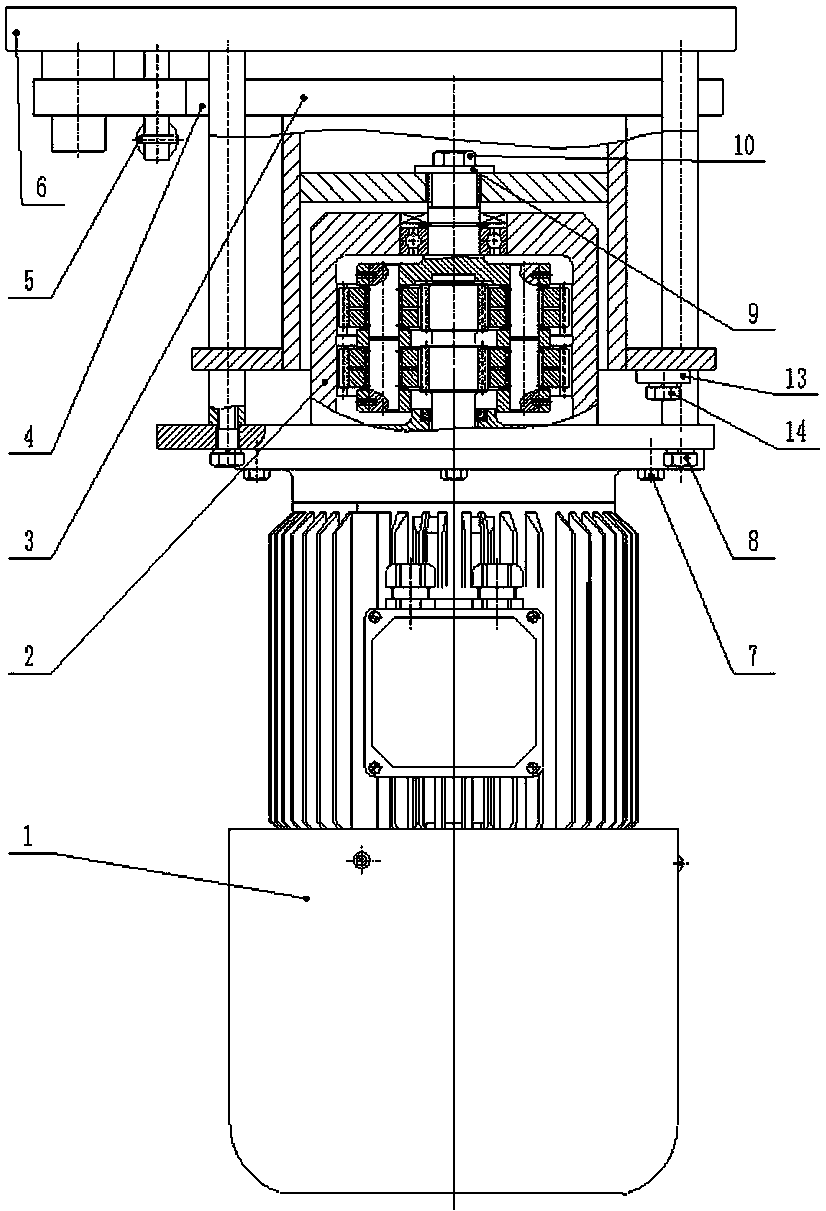

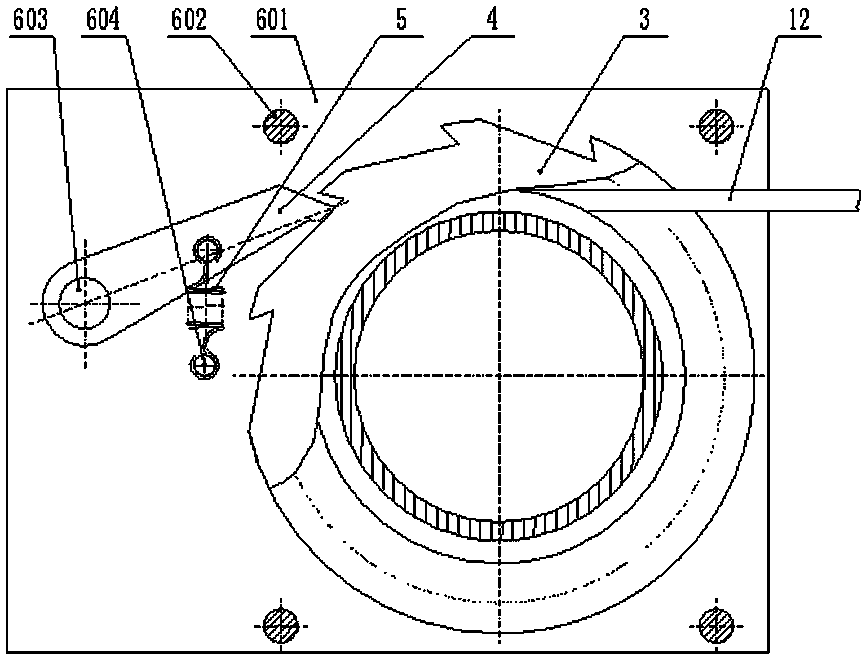

[0019] Figure 1 to Figure 5 As shown, the electric tensioning mechanism for the traction wire rope of the tower crane trolley is driven by the motor 1 through the planetary gear reducer 2 to drive the ratchet wheel 3 to rotate, and the ratchet wheel 3 winds the traction wire rope 12 to achieve the purpose of tensioning the traction wire rope 12; The pawl 4 is cut into the tooth groove of the ratchet 3 by the pulling force of the tension spring 5 to achieve the purpose of self-locking after the wire rope 12 is tensioned.

[0020] The output end of the electric motor 1 is connected with the input end of the planetary gear reducer 2, the electric motor 1 and the planetary gear reducer 2 are fixedly connected by the motor mounting bolt 7, and the planetary gear reducer 2 and the web rod 602 are connected by the reducer mounting bolt 8 Fixed connection. The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com