Special tool for hoisting of coal feeder

A special tool and coal feeder technology, which is applied in the field of special tools for hoisting coal feeders, can solve problems such as equipment overturning, rigging slippage, poor welding quality, etc., and achieve improved work efficiency, safe hoisting operations, and good promotion foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

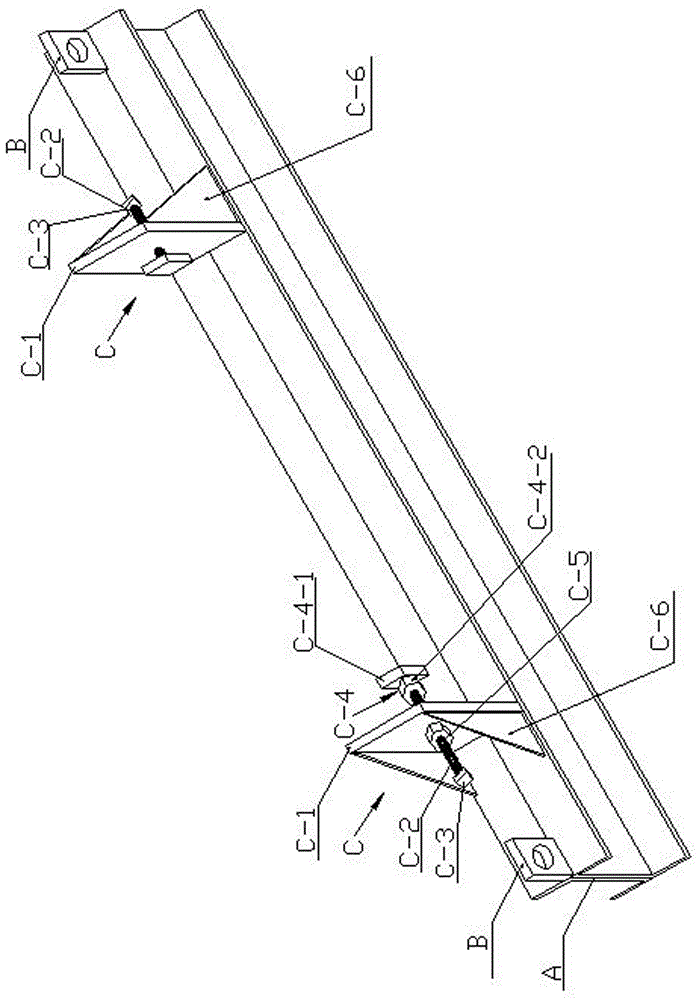

[0013] As shown in the figure, the special tool for hoisting the coal feeder includes a joist A, which is characterized in that lifting lugs B are welded on both ends of the joist A, and two clamping devices C are fixed on the middle of the joist A , The distance between the two clamping devices C matches the width of the coal feeder.

[0014] The clamping device C includes a vertical plate C-1, and there is a threaded hole in the middle of the vertical plate C-1, a threaded rod C-2 is screwed in the threaded hole, and a wrench block is provided at the tail end of the threaded rod C-2 C-3, the end of screw mandrel C-2 is screwed with chuck C-4, and vertical plate C-1 is welded on the upper plane of joist A.

[0015] The threaded hole in the middle of the vertical plate C-1 is formed by the nut C-5 welded on the vertical plate C-1, and a screw rod passes through the light hole in the middle of the vertical plate C-1.

[0016] The clamp C-4 is composed of a clamp C-4-1 and a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com