PC track beam evacuation passage construction operation vehicle

A technology of evacuation passages and track beams, which is applied in the direction of tracks, roads, bridges, etc., can solve the problems of large traffic impact, low construction efficiency, time-consuming and labor-consuming, etc., achieve high construction safety, improve construction efficiency, and reduce occupation. The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

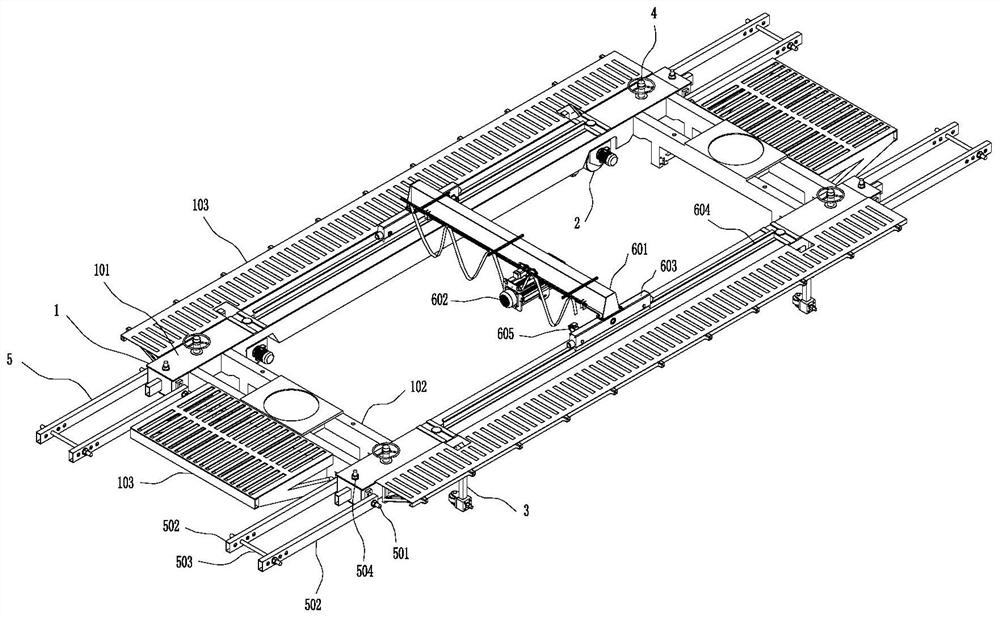

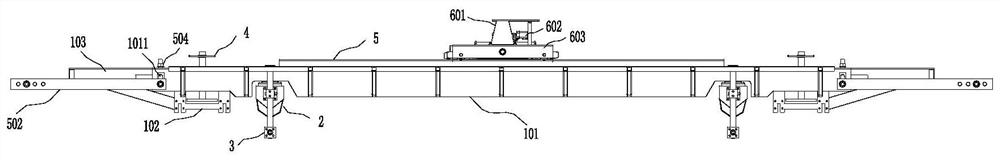

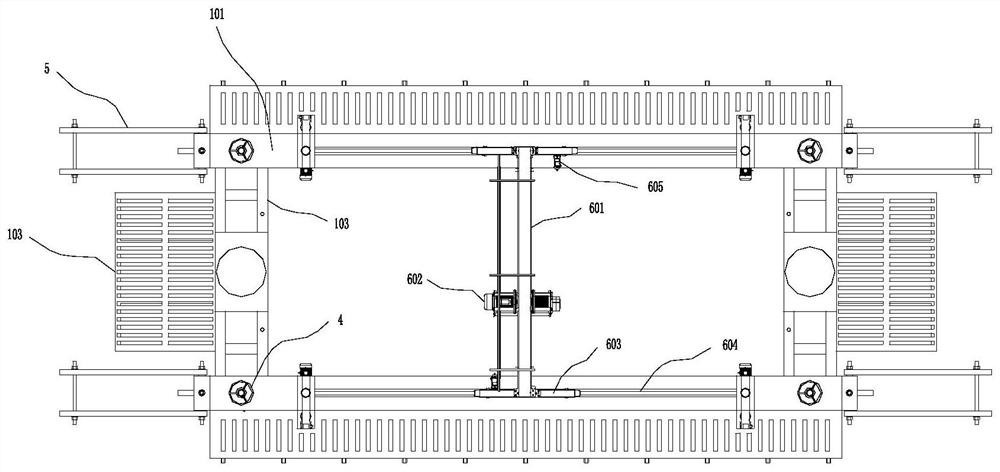

[0042] A PC track beam evacuation channel construction vehicle, please refer to Figure 1 to Figure 4 , comprising a vehicle frame 1, a traveling mechanism 2, a guiding mechanism 3, and a lifting assembly 6, which are used to lift the operating vehicle from the track beam 7 to make the traveling mechanism 2 detach from the track beam 7, and support the operating vehicle on the track beam 7 The load-bearing conversion assembly 4 is used to detachably connect the work vehicle to the parking lock assembly 5 fixed on the track beam 7; wherein, the vehicle frame 1 includes a longitudinal beam 101 and a cross beam 102, and the longitudinal beam 101 and the cross beam 102 are connected to form an interior Frame structure with hoisting and installation construction space.

[0043] Further, in a preferred embodiment, see Figure 1 to Figure 5 The load-bearing conversion assembly 4 includes a shaft sleeve 401 arranged on the longitudinal beam 101, a screw rod 402 threaded through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com