Inversely assembling process for standing stay wire V-type tower

An assembly and inversion technology, applied to towers, building types, buildings, etc., can solve problems such as large stress on tool systems and high safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific examples.

[0036] In order to overcome the shortcomings of the traditional construction technology in the background technology, the present invention provides an improved flip-chip assembly process for V-shaped towers, which is suitable for the construction of tall and heavy V-shaped towers.

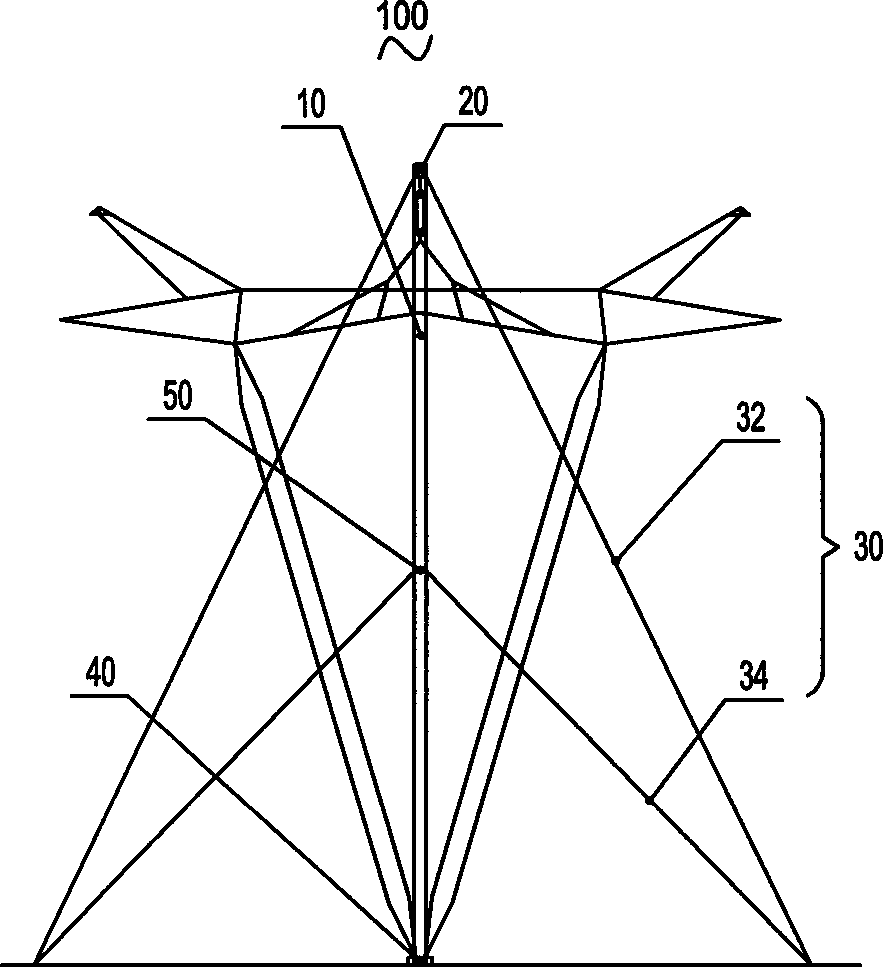

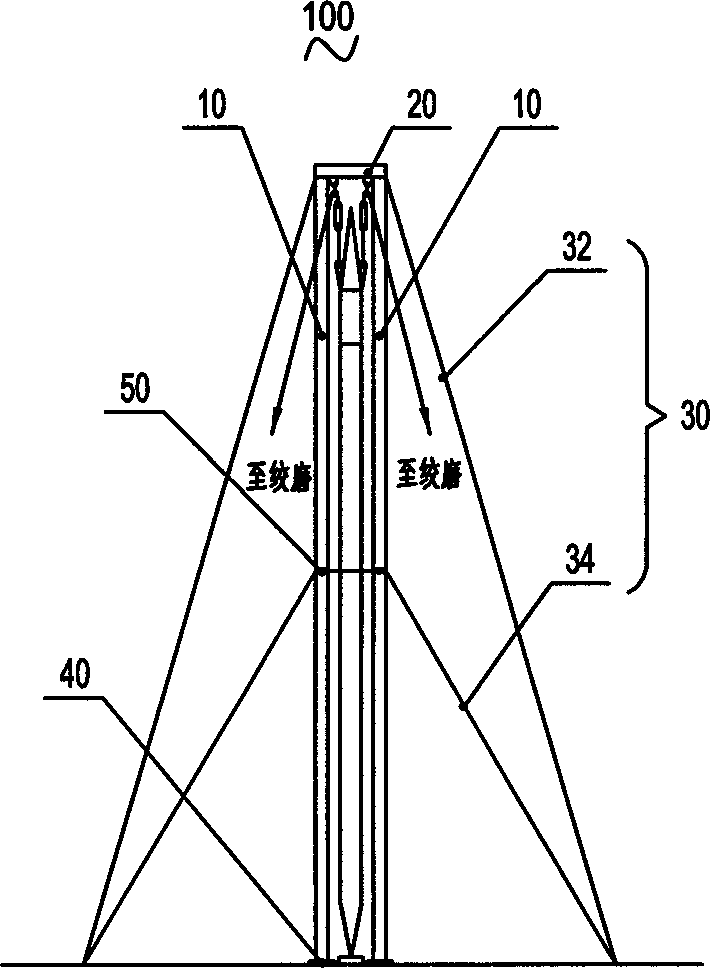

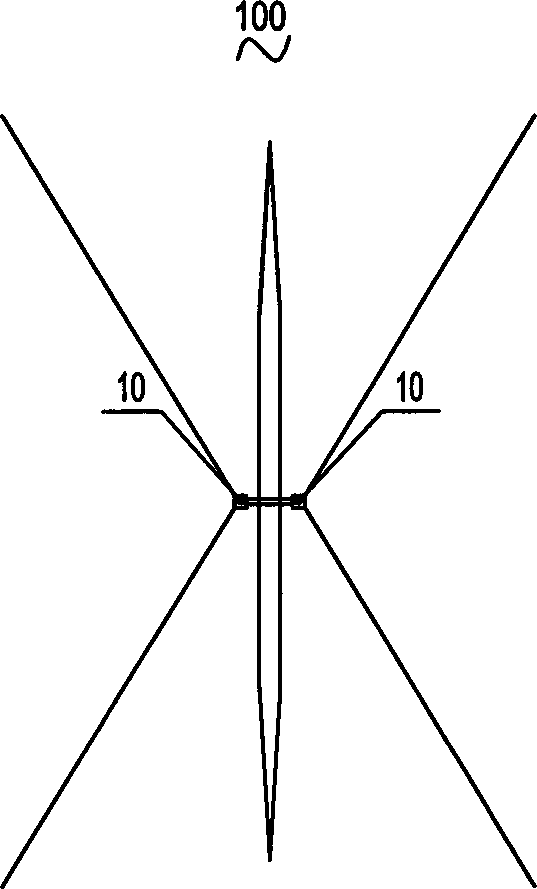

[0037] In order to adapt to the upside-down assembly of large-scale pull-V towers, the present invention provides a supporting tool for hoisting construction—portal frame 100 . The portal frame 100 includes two upright columns 10 , a crossbeam 20 , a floor stay wire 30 , a base 40 , a waist board 50 and a waist rope 60 . The uprights 10 stand on the ground through the base 40 , and the beam 20 connects the two uprights 10 from the tops of the two uprights 10 . The floor guy wire 30 includes two layers of floor guy wires—an upper floor guy wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com