Controllable one-way clutch

A one-way clutch and standard technology, applied in the field of clutches, can solve the problems of selecting the direction of transmission, inability to control the opening and closing of the one-way rotation function, etc., and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution will be described in detail below in conjunction with specific embodiments.

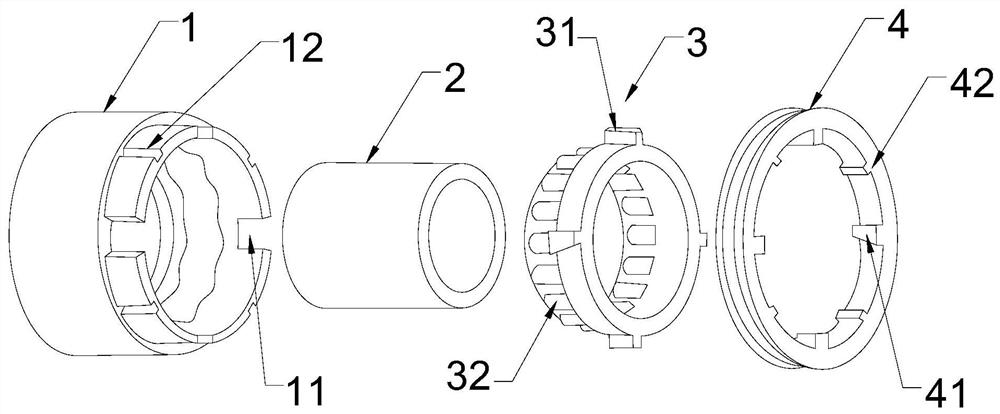

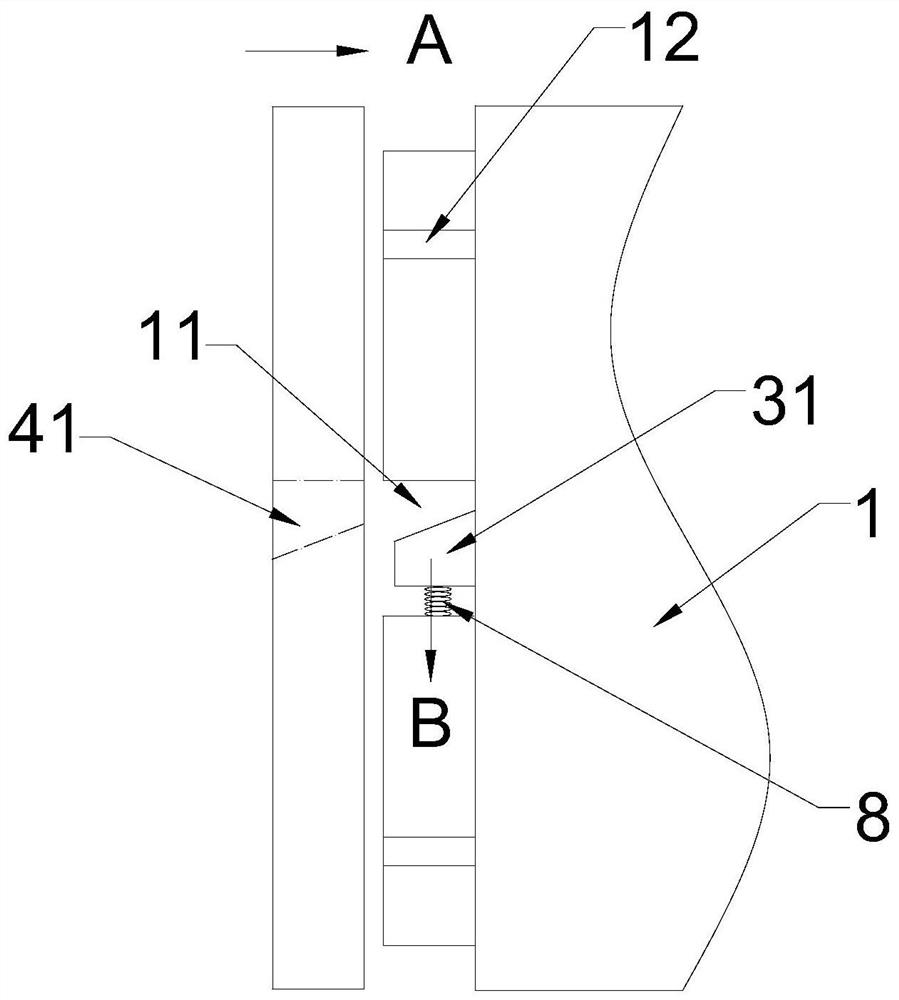

[0019] Such as Figure 1-5 As shown, the present invention is a controllable one-way clutch, including a control sleeve 4, a roller control ring 3, an inner ring 2 and an outer ring 1, wherein the roller control ring 3 includes a square roller hole 32, a roller 7. The inner ring 2 is arranged inside the outer ring 1, and a set of control sleeve 4 and roller control ring 3 are arranged at one end of the inner and outer ring. The roller hole 32 is set on the ring of the control ring 3, and the roller 7 is installed on the roller hole 32. One end of the roller 7 is in contact with the outer peripheral wall of the inner ring 2, and the other end is in contact with the inner peripheral wall 10 of the outer ring 1. .

[0020] The connecting portion of the roller control ring 3 is also equipped with a right-angled trapezoidal limit block 31, and a control sleeve 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com