Hot-melt extrusion welding composite heat shrinkable tape connected HDPE pipe and construction method thereof

A technology of hot-melt extrusion and heat-shrinkable tape, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, pipe, etc., which can solve the problems of low construction efficiency, time-consuming, misplaced pipe connection, etc., and achieve stable connection, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

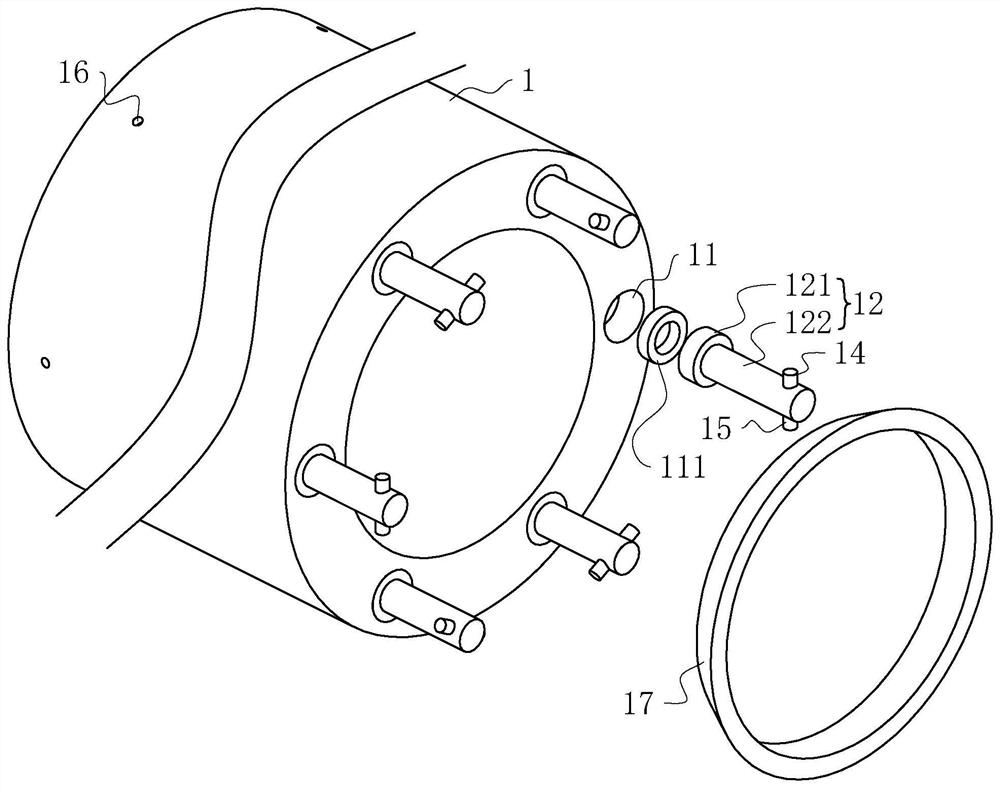

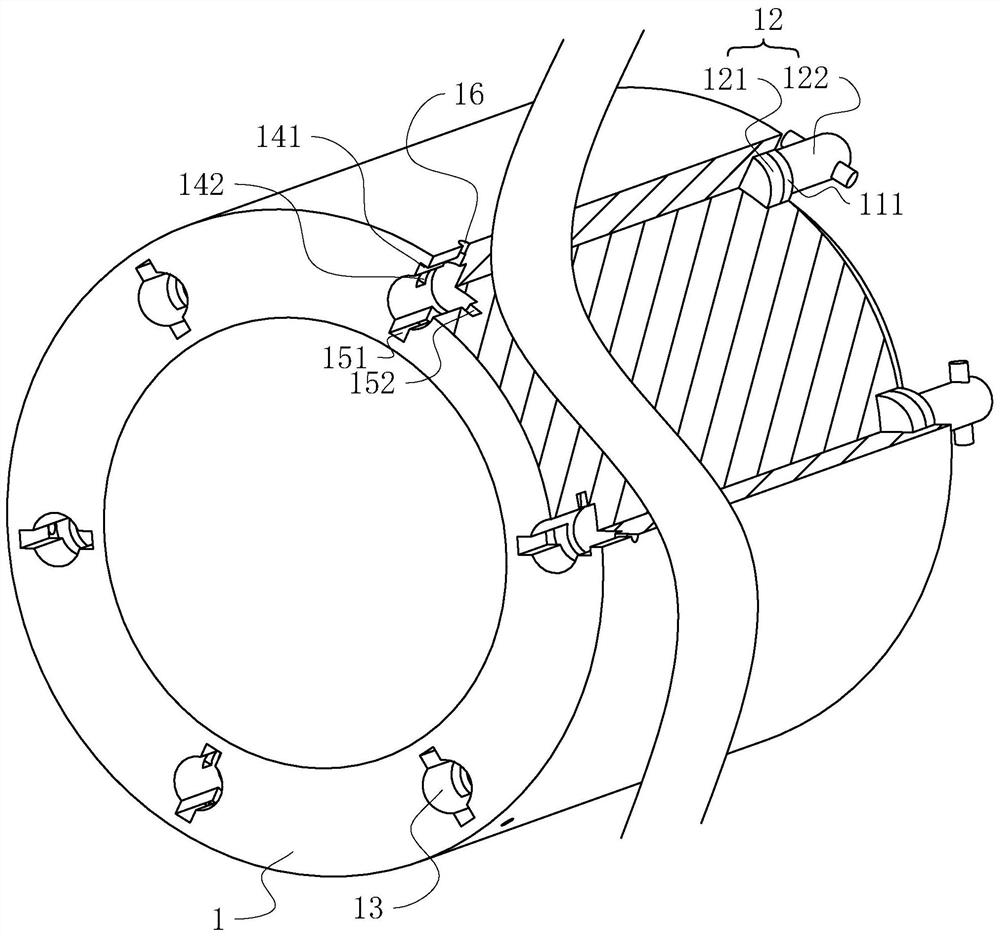

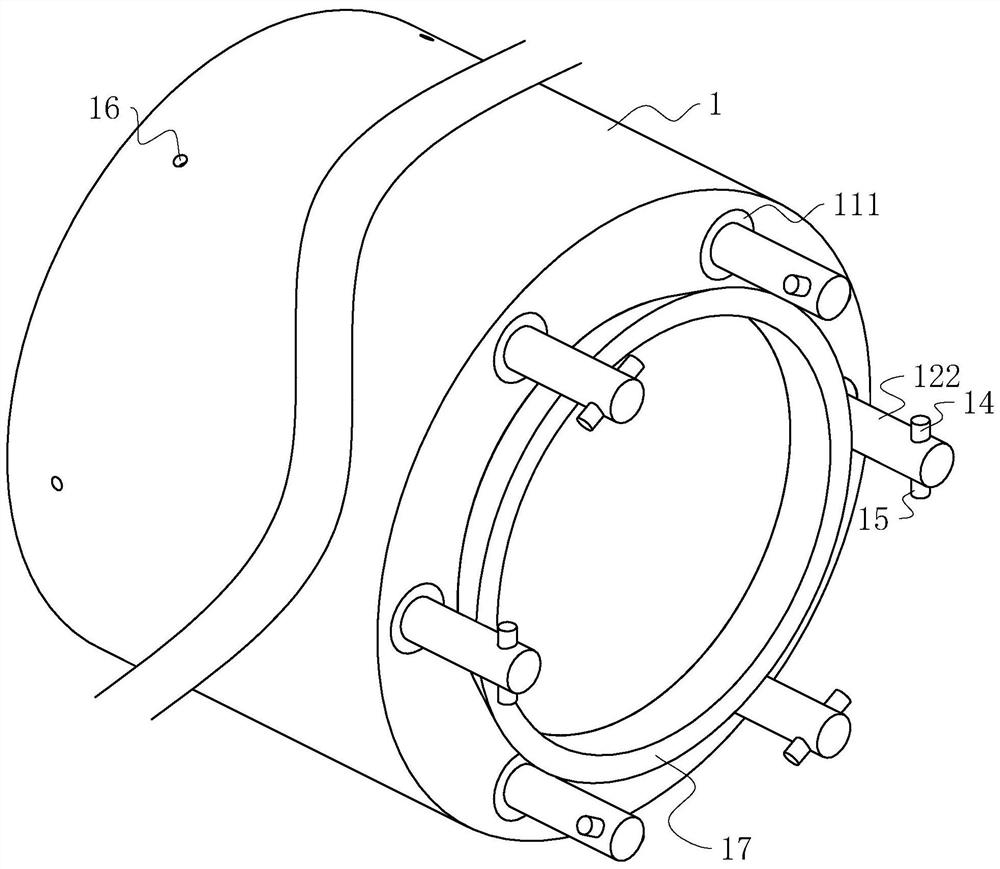

[0045] The following is attached Figure 1-3 The application is described in further detail.

[0046]The embodiment of the present application discloses a HDPE pipe connected by a hot-melt extrusion welding composite heat-shrinkable tape.

[0047] refer to figure 1 and figure 2 , a HDPE pipe connected by hot-melt extrusion welding composite heat-shrinkable tape, including a pipe body 1, a plurality of accommodation grooves 11 are equally spaced on one end surface of the pipe body 1, and a positioning rod 12 is arranged in each accommodation groove 11 The end surface of the pipe body 1 away from the positioning rod 12 is provided with a plurality of positioning grooves 13 corresponding to the positioning rod 12 . When two pipe bodies 1 are connected, the positioning rod 12 of one pipe body 1 can be correspondingly inserted into the positioning groove 13 of the other pipe body 1 .

[0048] refer to figure 1 and figure 2 The positioning rod 12 is T-shaped and includes a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com