Steel ball locking quick connector

A steel ball and fast technology, applied in mechanical equipment, couplings, etc., can solve the problems of complex overall joint structure, inconvenient assembly operation, limited operation space, etc., to achieve simple and easy operation, precise and fast docking, The effect of smooth internal circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

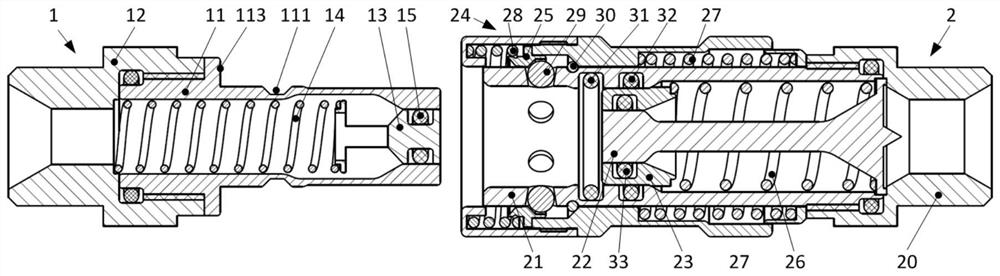

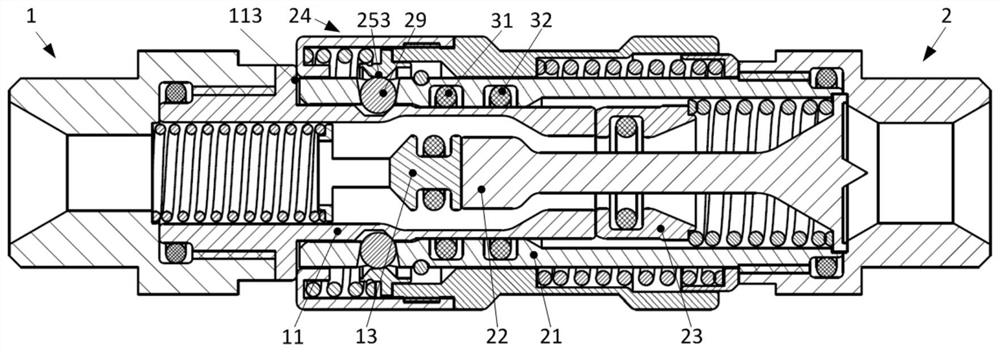

[0039] Example 1, such as Figure 1 to Figure 3 As shown, the present application proposes a new type of steel ball locking quick joint, which includes a male joint 1 and a female joint 2 . specifically,

[0040] The male joint 1 has a male end front housing 11 and a male end rear housing 12 connected by internal and external threads, and a sealing member for sealing is also provided at the thread end; the male end front housing 11 and the male end rear housing The inner cavity of the housing 12 is connected to form a first channel that runs through the front and rear ends of the integral male connector 1;

[0041] In the inner cavity of the front housing 11 of the male end, a male valve core 13, a valve core elastic member 14 and a male end seal 15 are arranged; Between the cores 13, under the elastic support of the valve core elastic member 14, the valve core 13 can reciprocate in a linear motion in the first channel; the male end seal 15 provides self-sealing at the front...

Embodiment 2

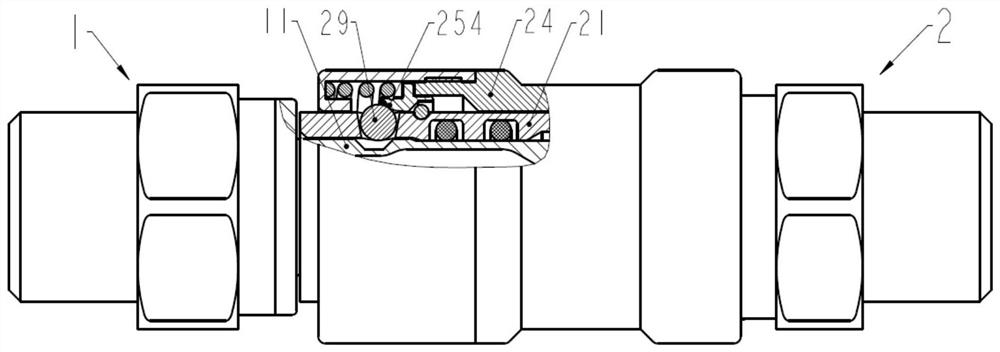

[0050] Example 2, such as Figure 4 As shown, the groove 111 outside the front housing 11 of the male connector can have a cross-sectional shape of trapezoidal, semi-oblong or elliptical;

[0051] The inner cavity of the housing 11 in front of the male joint has at least one set of enlarged flow chambers 112 to correspondingly expand the cross-sectional area of the first channel and reduce the flow resistance.

[0052] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] Example 3, such as Figure 5 As shown, the valve core 13 is provided with a valve core limit support 131 for supporting the valve core elastic member 14 at its end, and the valve core limit support 131 can be an inner support or an outer support structure.

[0054] A trapezoidal hollow structure 132 is provided through the pipe wall of the valve core 13 to provide good guidance and flow area for fluid flow.

[0055] Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com