A Two-dimensional Grating for High-Resolution and High-Precision Plane Displacement Measurement

A two-dimensional grating and displacement measurement technology, applied in the field of two-dimensional gratings, can solve the problem that absolute plane displacement measurement cannot be solved well, and achieve two-dimensional plane displacement measurement, simple and convenient image recognition, and high resolution. and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

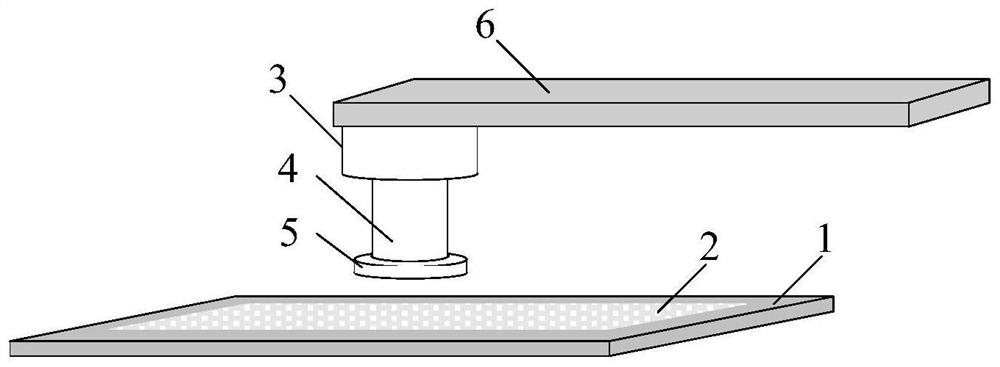

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

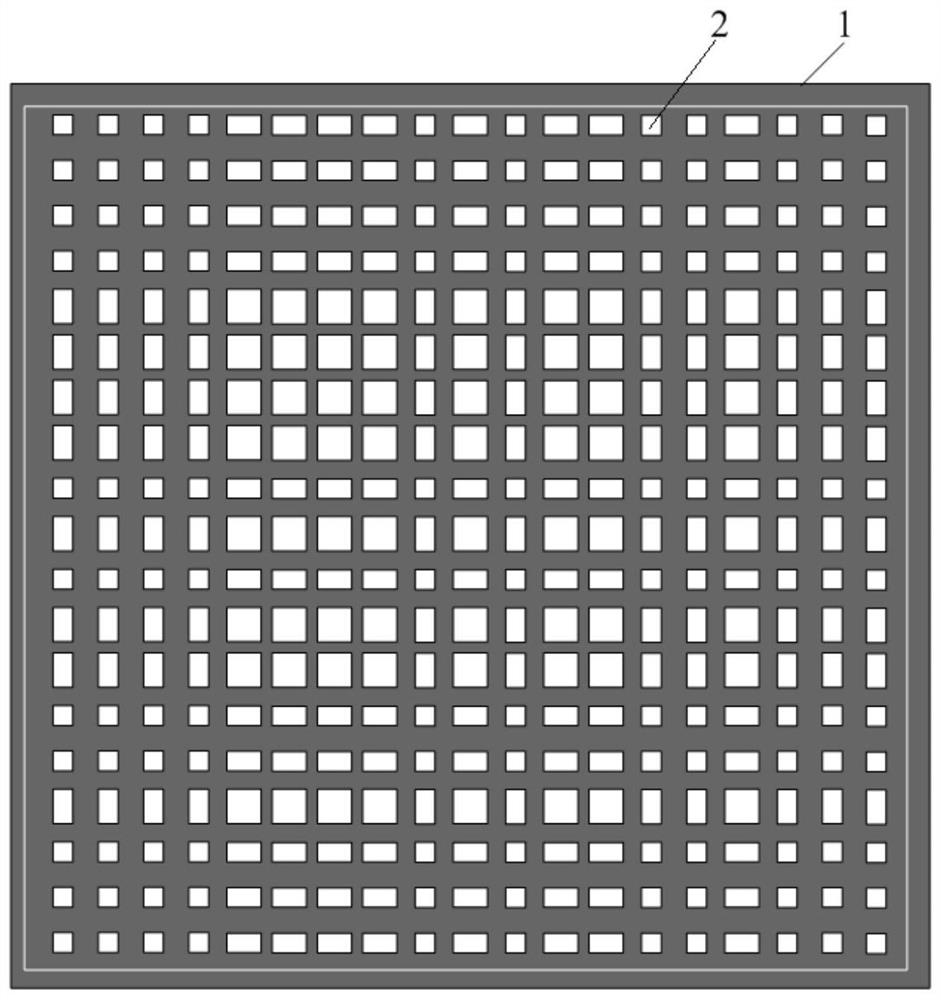

[0036] refer to figure 1 , a (16×16)-bit coded two-dimensional grating disclosed in an embodiment of the present invention, comprising: a disk body 1 and coded marking lines 2 . The coding marking line 2 is engraved on the disc body 1 . The disc body 1 is an opaque square disc made of glass or metal coated with an opaque film.

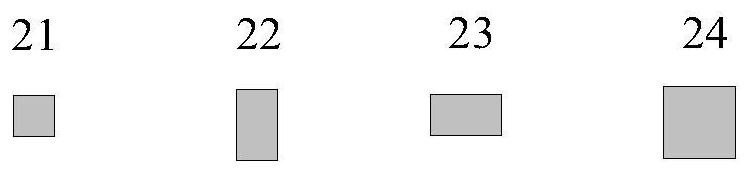

[0037] refer to figure 2 , a schematic diagram of the shape of the coding marking line disclosed in the embodiment of the present invention, including: shape one 21 , shape two 22 , shape three 23 , and shape four 24 . Let the horizontal coding value be x, and the vertical coding value be y, then the coding value represented by shape 1 is {x=0, y=0}, shape 2 is {x=1, y=0}, and shape 3 is {x= 1, y=1}, the shape four is {x=0, y=1}.

[0038] The first shape 21, the second shape 22, the third shape 23, and the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com