Membrane cleaning device and membrane cleaning method

A technology for membrane cleaning and membrane separation, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as reduced filtration performance and clogging, and achieve the effects of reducing costs and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

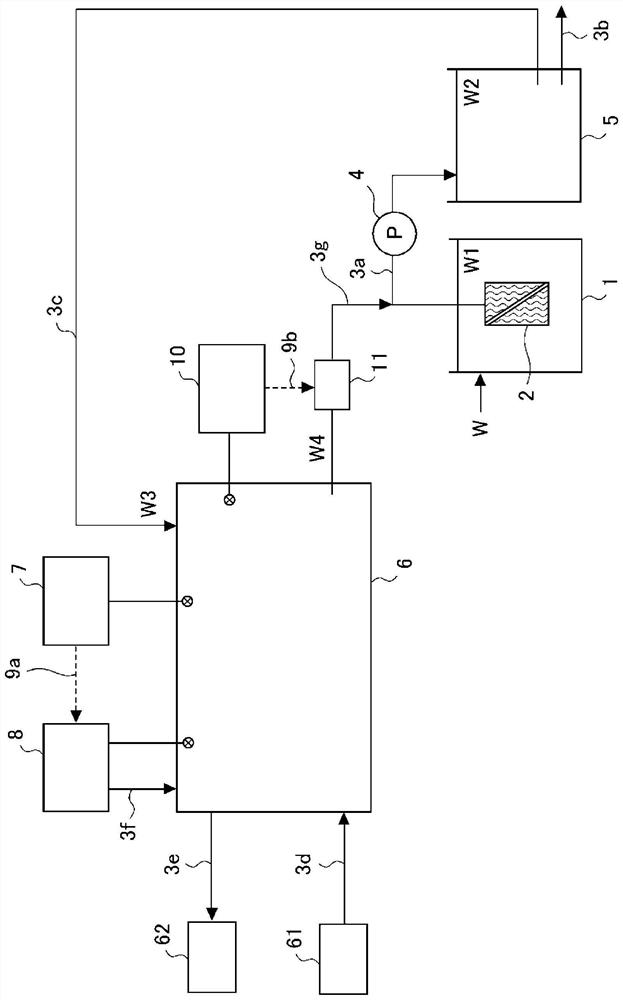

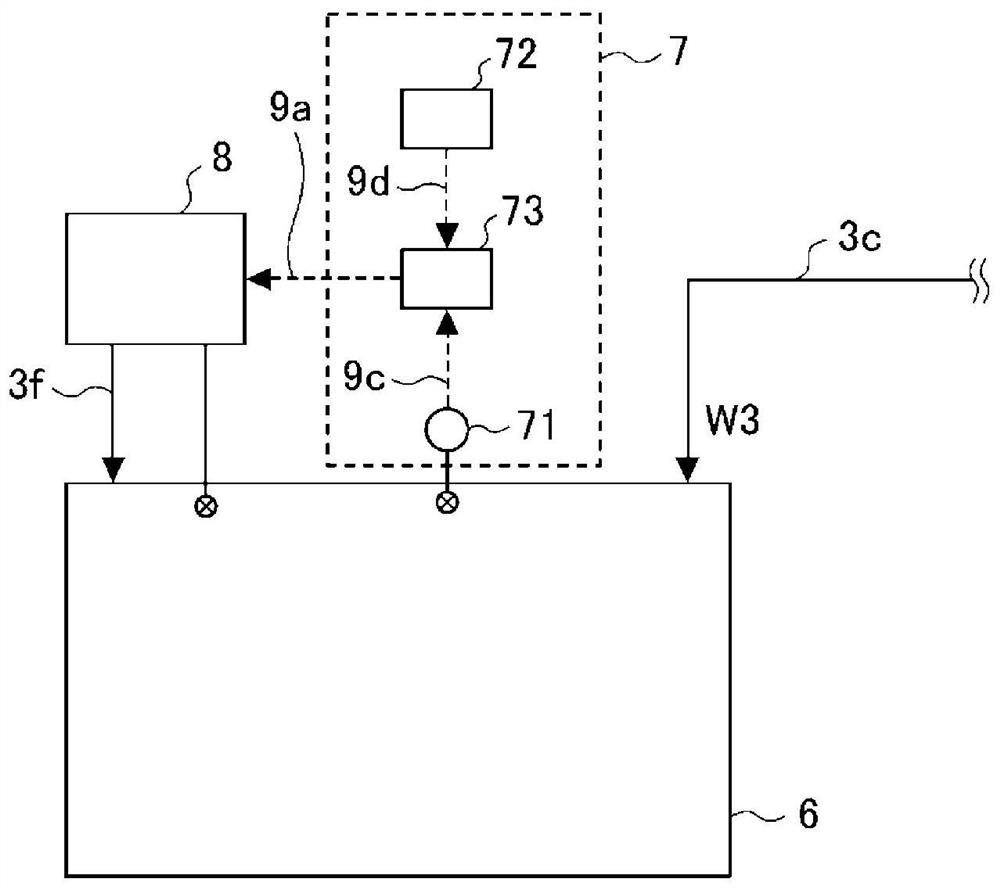

[0035]Hereinafter, the membrane cleaning device and membrane cleaning method according to the first embodiment of the present application will be described based on the drawings.figure 1 The overall configuration of the membrane cleaning device according to Embodiment 1 is shown. In addition,figure 2 ,image 3 andFigure 4 The configurations of the process transition determination unit, the pH adjustment unit, and the water supply start determination unit of the membrane cleaning device according to Embodiment 1 are shown respectively. In each figure, the same reference numerals are given to the same and corresponding parts.

[0036]For the overall configuration of the membrane cleaning device according to Embodiment 1, usefigure 1 Let's briefly explain. The membrane cleaning device, for example, in a water treatment system using MBR, cleans the separation membrane 2 that separates the water to be treated W1 containing activated sludge into activated sludge and treated water W2. It shoul...

Embodiment approach 2

[0077]Picture 8 Shows the overall configuration of the membrane cleaning device according to Embodiment 2 of the present application,Picture 9 The configuration of the process transition judging unit of the membrane cleaning device according to Embodiment 2 is shown. Regarding the membrane cleaning device according to the second embodiment, only the configuration of the process transition judging unit is different from the membrane cleaning device according to the above-mentioned first embodiment, and the other configurations are the same, so the description is omitted here.

[0078]The membrane cleaning apparatus according to Embodiment 2 includes a process transition judging unit 7A. As far as the process transfer judgment unit 7A is concerned,Picture 9 As shown in FIG. 1, an organic matter sensor 74, an ozone gas sensor 75, a memory (third memory) 72A, and a comparison unit (third comparison unit) 73A are provided. The organic matter sensor 74 and the comparison unit 73A, the ozone ...

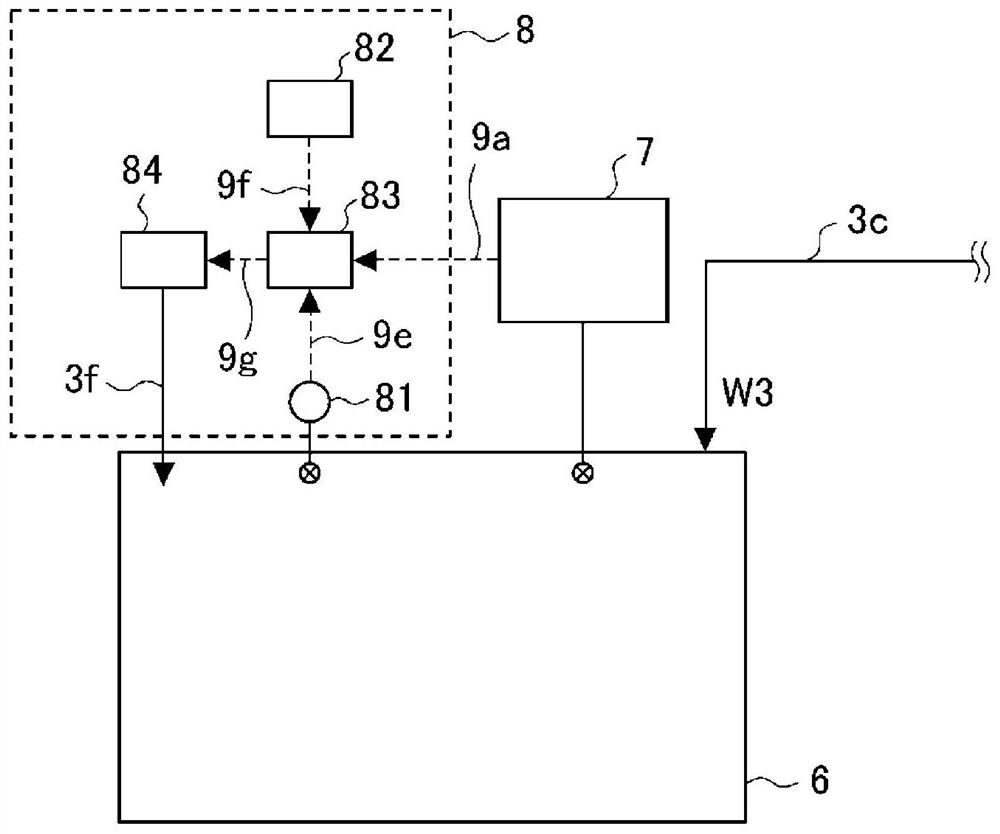

Embodiment approach 3

[0088]Picture 11 The overall configuration of the membrane cleaning device according to Embodiment 3 of the present application is shown. Regarding the membrane cleaning device according to the third embodiment, only the configuration of the process transition judging unit is different from the membrane cleaning device according to the above-mentioned first embodiment, and the other configurations are the same, so the description is omitted here.

[0089]The membrane cleaning apparatus according to Embodiment 3 includes a process transition judging unit 7B. With regard to the process transition judging unit 7B, such asPicture 11 As shown in the figure, it includes a dissolved ozone sensor 76, an ozone gas sensor 75, a memory (fourth memory) 72B, and a comparison unit (fourth comparison unit) 73B. The dissolved ozone sensor 76 and the comparison unit 73B, the ozone gas sensor 75 and the comparison unit 73B, the memory 72B and the comparison unit 73B, and the comparison unit 73B and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com