Steam generating system

A technology for generating system and steam, applied in the direction of steam generation, steam generation device, steam generation method, etc., can solve the problems such as the inability to ensure the steam in the ship and the inability to use the exhaust gas economizer to recover energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

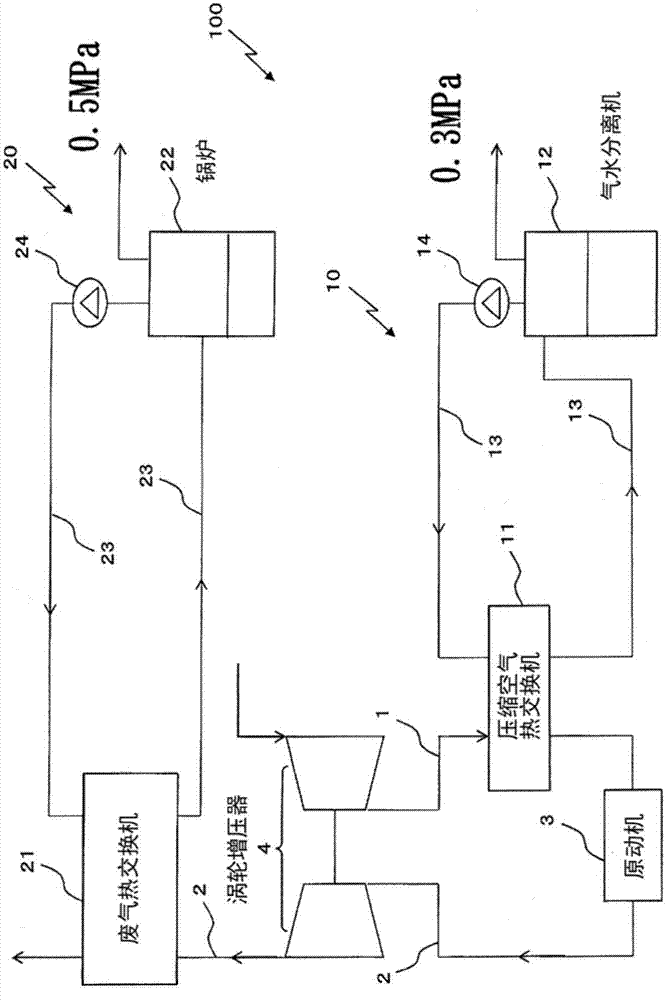

[0028] Next, refer to figure 1 , the steam generating system according to the embodiment of the present invention will be described. figure 1 It is a configuration diagram of the steam generating system 100 according to the embodiment of the present invention. The steam generating system 100 is used to generate steam on board a ship, and includes a scavenging side steam generating unit 10 and an exhaust gas side steam generating unit 20 using waste heat from a prime mover 3 (engine or generator). Furthermore, the steam used in the ship is divided into a low-pressure system (0.3 MPa in this embodiment) and a high-pressure system (0.5 MPa in this embodiment), so that low-pressure steam is generated in the scavenging side steam generation unit 10, and the exhaust gas The side steam generator 20 generates high-pressure steam. The medium used in this embodiment is water.

[0029] In addition, the numerical value of low-pressure steam and high-pressure steam can be changed suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com