Egg steaming robot system

A robot system and robot technology, applied in the field of egg steaming robot system, can solve the problems of reducing the economic benefit and use value of egg food processing equipment, unable to accurately control water volume, water temperature, manpower and energy waste, etc., and achieve significant economic benefits and Use value, complete structure, and the effect of solving human and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

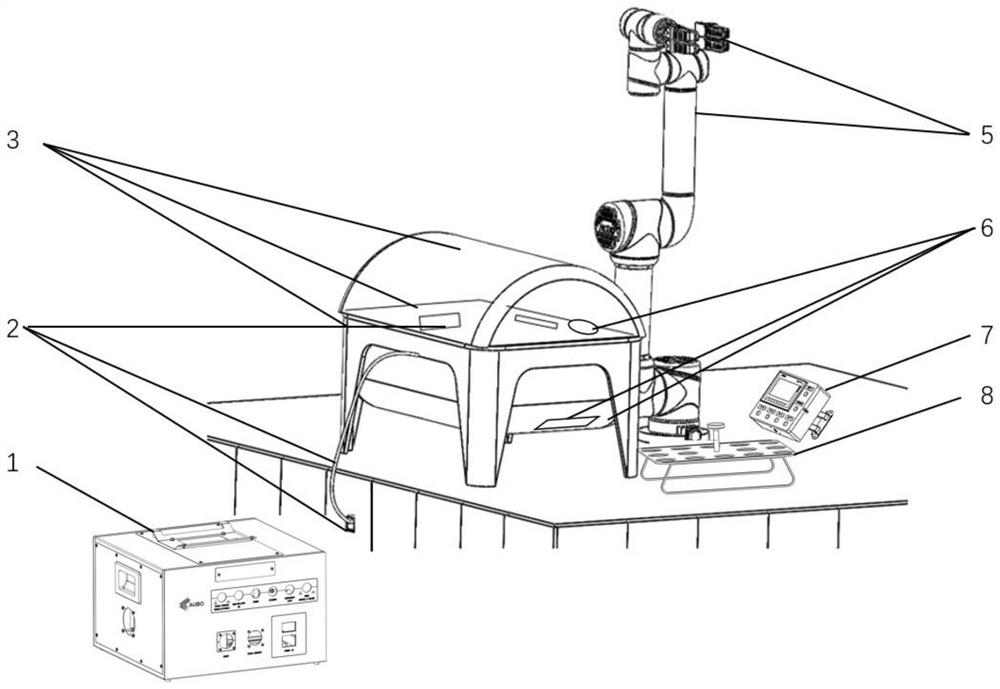

[0017]Example 1

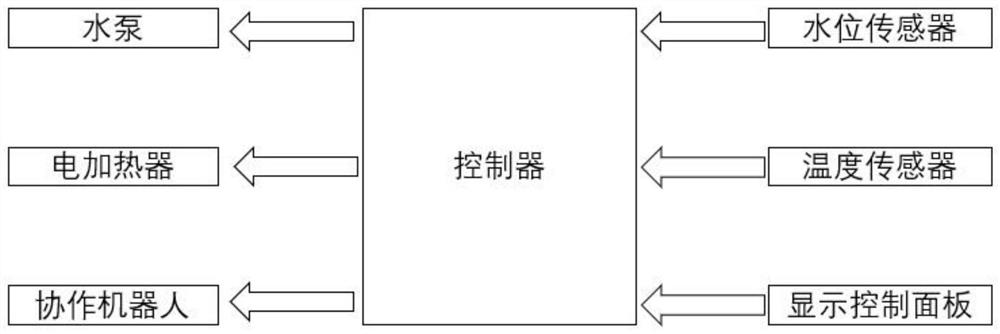

[0018]The present invention provides a steaming egg robot system, which is characterized in that it includes a timing water adding system 2, an adjustable temperature control system 6, an open-hole steamer 3, a steaming egg tray 8, a collaborative robot 5, a controller 1, a display control panel 7. Desktop; the left side of the desktop is equipped with a controller 1, and the desktop is equipped with a timing water adding system 2, an open-hole steamer 3, a display control panel 7, an adjustable temperature control system 6, a collaborative robot 5, and steamed eggs Tray 8, the table top is provided with a perforated steamer 3 through a fixed leg, the perforated steamer 3 is provided with a timing water addition system 2 inside, and the perforated steamer 3 is provided with an adjustable temperature control system, with perforations A collaborative robot 5 is provided on the right side of the steamer 3, a display control panel 7 is provided on the right of the collabo...

Example Embodiment

[0024]Example 2

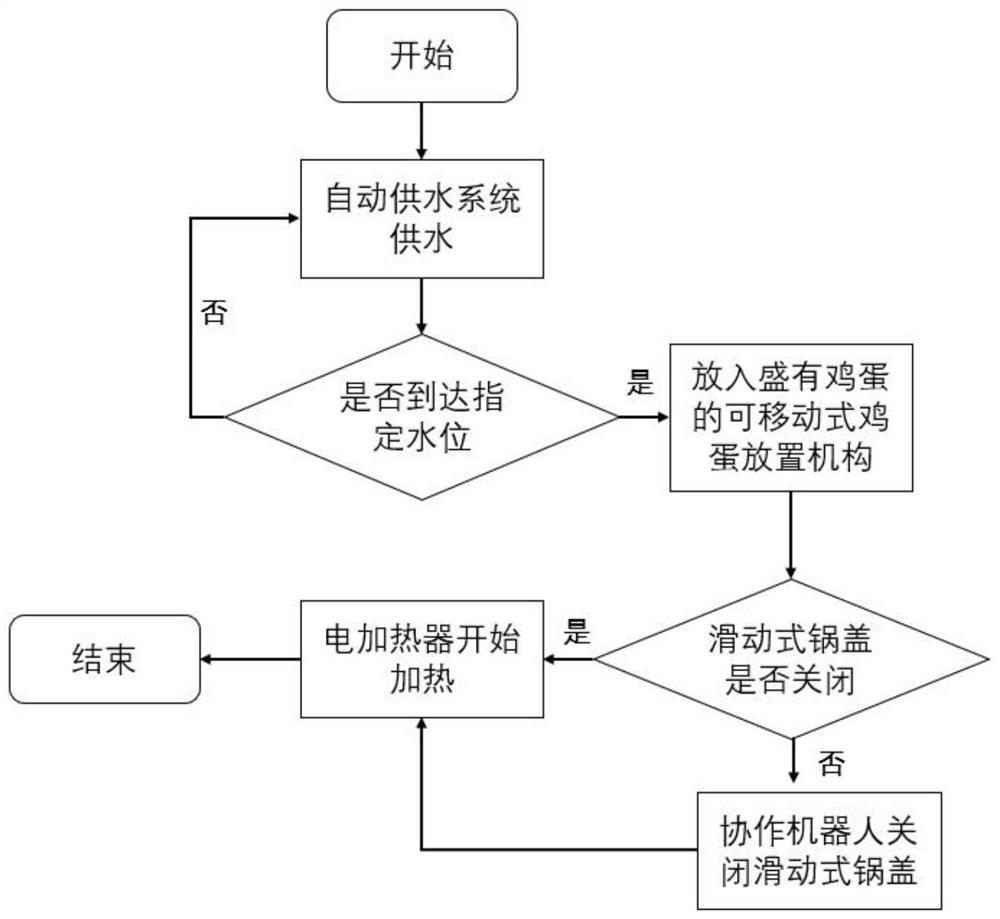

[0025]The timing water addition system 2 completes the automatic water addition of the steamed egg tank through the controller 1 and the water level sensor. At the same time, when the water level is lower than the set safe water level during the egg steaming process, the water level sensor is triggered to send a signal to the controller 1, and the controller 1 sends Instruct the water supply pump, and the water pump will start filling the steamed egg tank until it reaches the set water level;

[0026]Adjustable temperature control system 6 After the automatic timing water filling system 2 enters the specified water level, the electric heater starts to heat up. The heating time can be set by the collaborative robot 5 through the input keyboard. After the set time interval is heated, it will jump to Keep warm mode; when the steamed eggs are taken out and the steamed egg tray 8 containing raw eggs is placed into the steamed egg tank, the metal sensor at the bottom of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com