Standardized propulsion model construction curve graph drawing equipment and method thereof

A construction method and graph technology, applied in the field of standardized models, can solve the problems of lack of standardized model construction and evaluation in the high-end new electronic information industry, poor automation structure design of graph drawing equipment, and difficult scientific transformation of technical achievements, etc., to achieve automation The effect of high level, large drawing size and scientific standardized process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

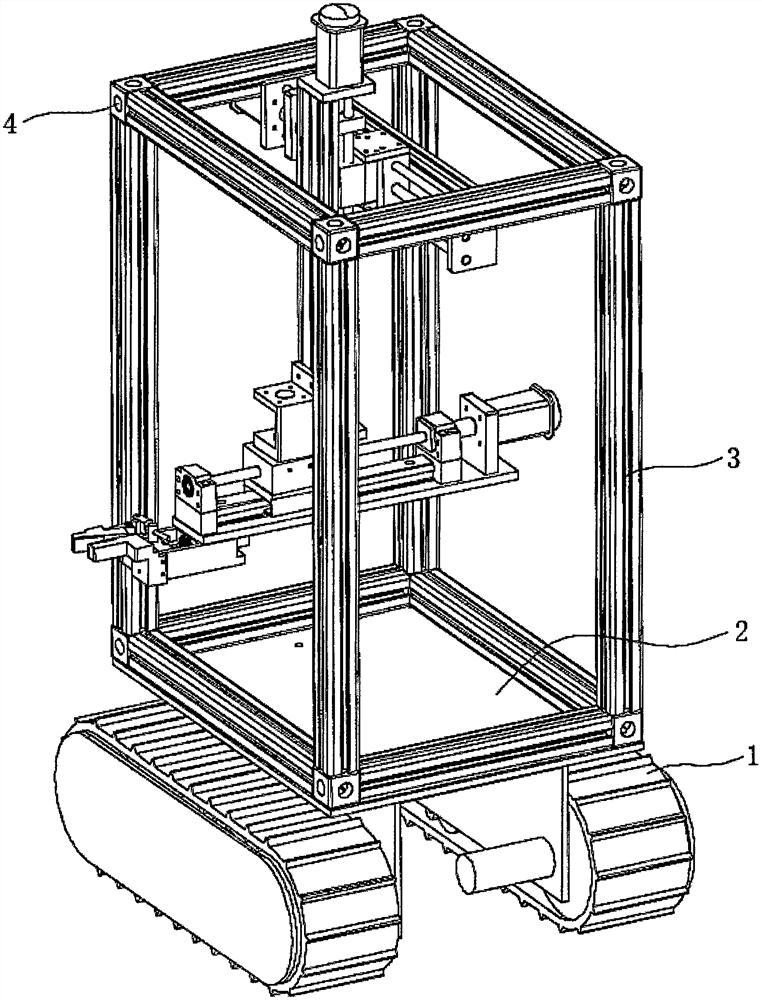

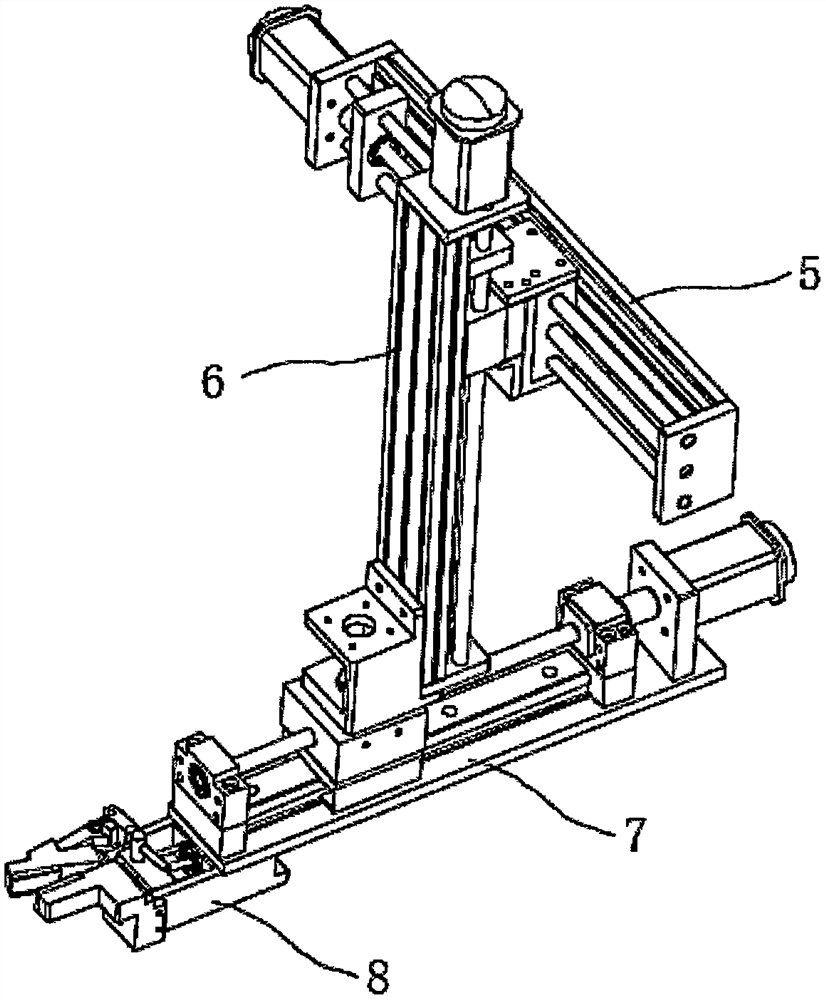

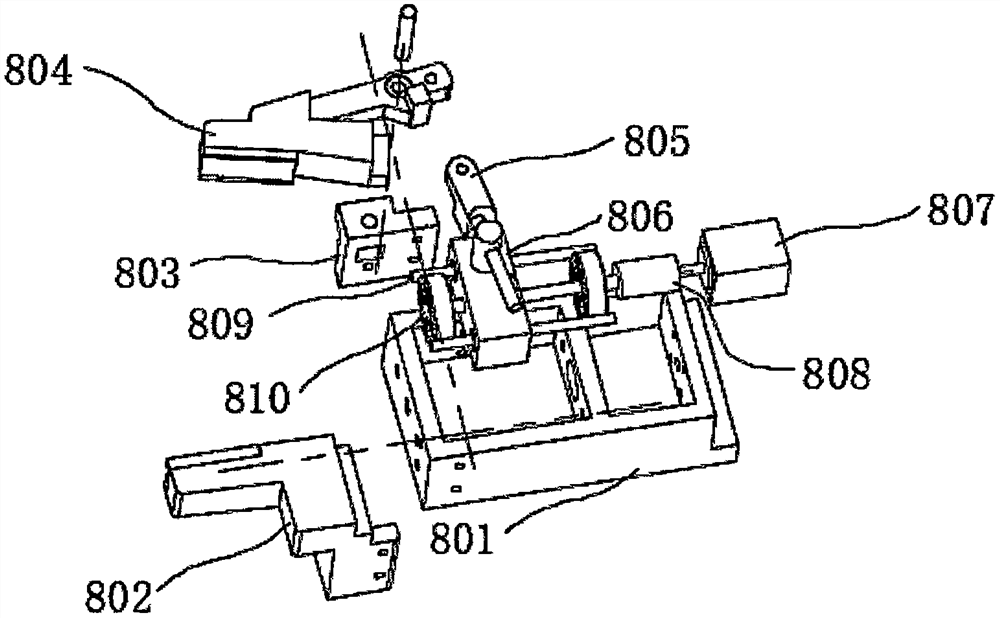

[0018] The structure and use of the present invention will now be further described with reference to the accompanying drawings. The standardization promotion model construction method includes the transformation of independent innovation achievements, the industrialization of technological achievements, and the standardization of technological achievements. The transformation of independent innovation achievements includes five steps: determining patents → determining products → determining feasibility → trial production, trial sales → mass production, marketing and improvement, the industrialization of technological achievements includes market strategy, alliance strategy and intellectual property strategy, and the standardization of technological achievements includes the proposed industrial standard system framework, industrial technical standards and industrial standardization roadmap; it is characterized in that the transformation of independent innovation achievements inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com