Method for preparing nano black TiO2 by aerosol method

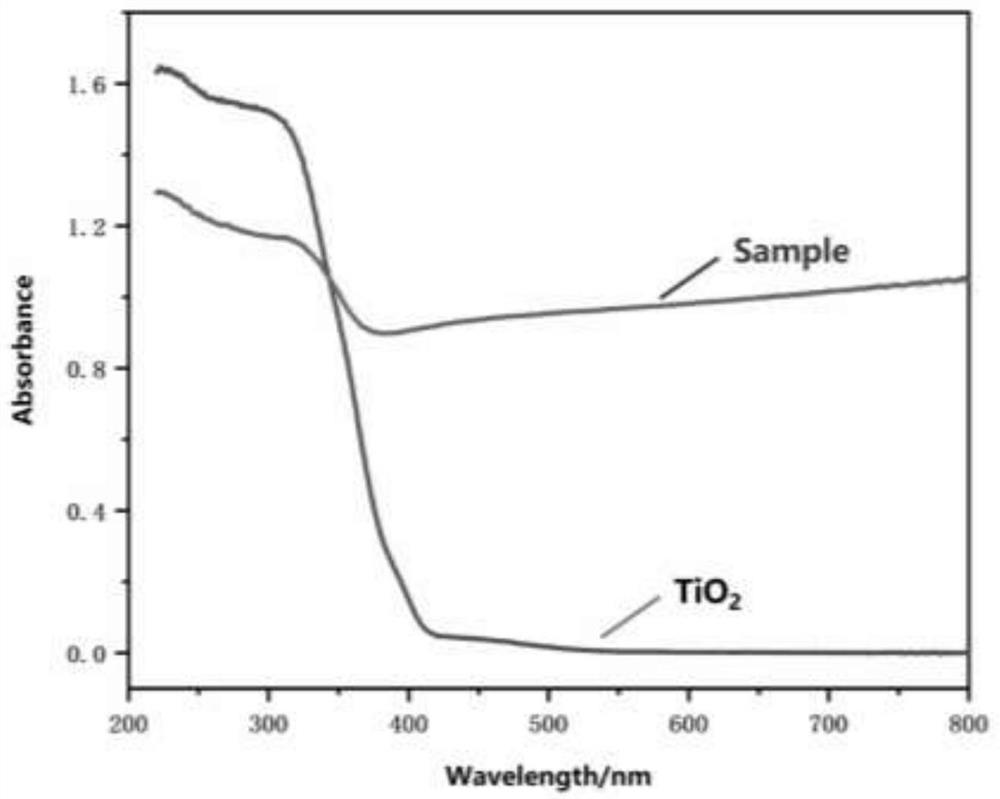

An aerosol and black technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as insufficient solar energy utilization efficiency, complicated preparation methods, and inability to meet performance requirements, etc., to achieve excellent Photocatalytic performance, wide source of raw materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of nano-black TiO by an aerosol method 2 method, including the following steps:

[0035] Weigh 10g of n-butyl titanate and 100g of absolute ethanol respectively, pour them into a beaker, and mix them uniformly by ultrasonic to obtain a homogeneous precursor solution; 2 As the carrier gas, and the pressure of the carrier gas is controlled to 0.1Mpa, the precursor solution is atomized into 2μm aerosol droplets through the atomizer, and then sent to a tube furnace at 600°C for 3-4s; the obtained sample powder is collected , that is, black TiO 2 nanoparticles.

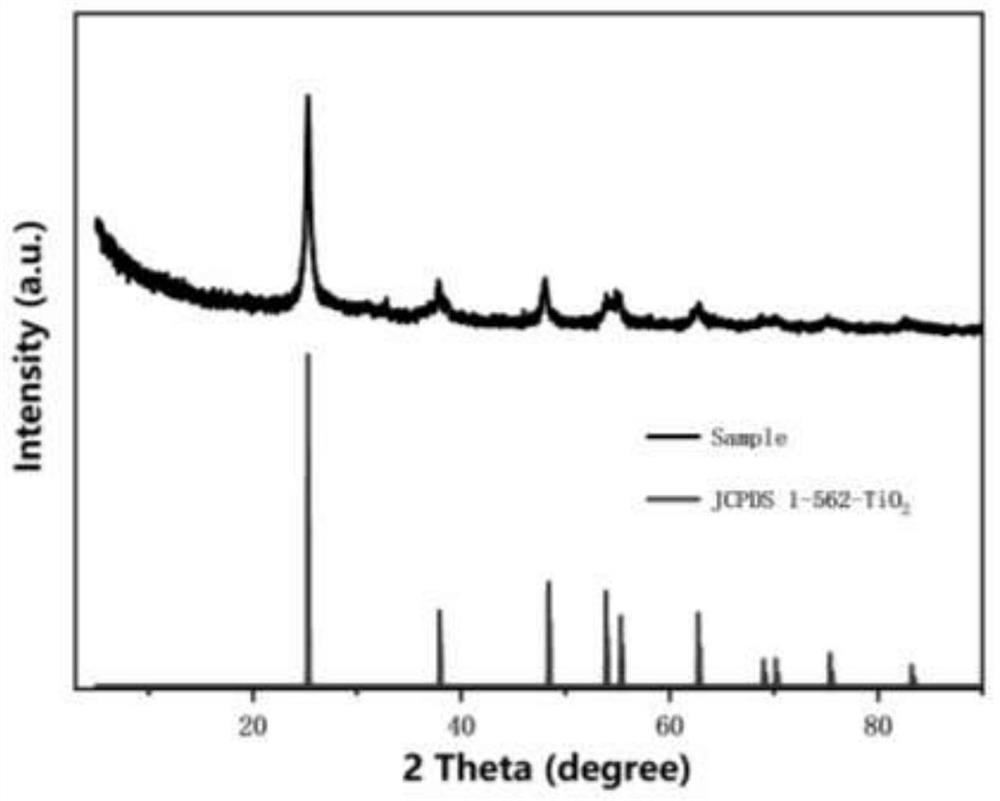

[0036] The product obtained in this embodiment is analyzed by X-ray diffraction, the results are shown in figure 1 ,Depend on figure 1 It can be seen that the obtained product is anatase TiO 2 .

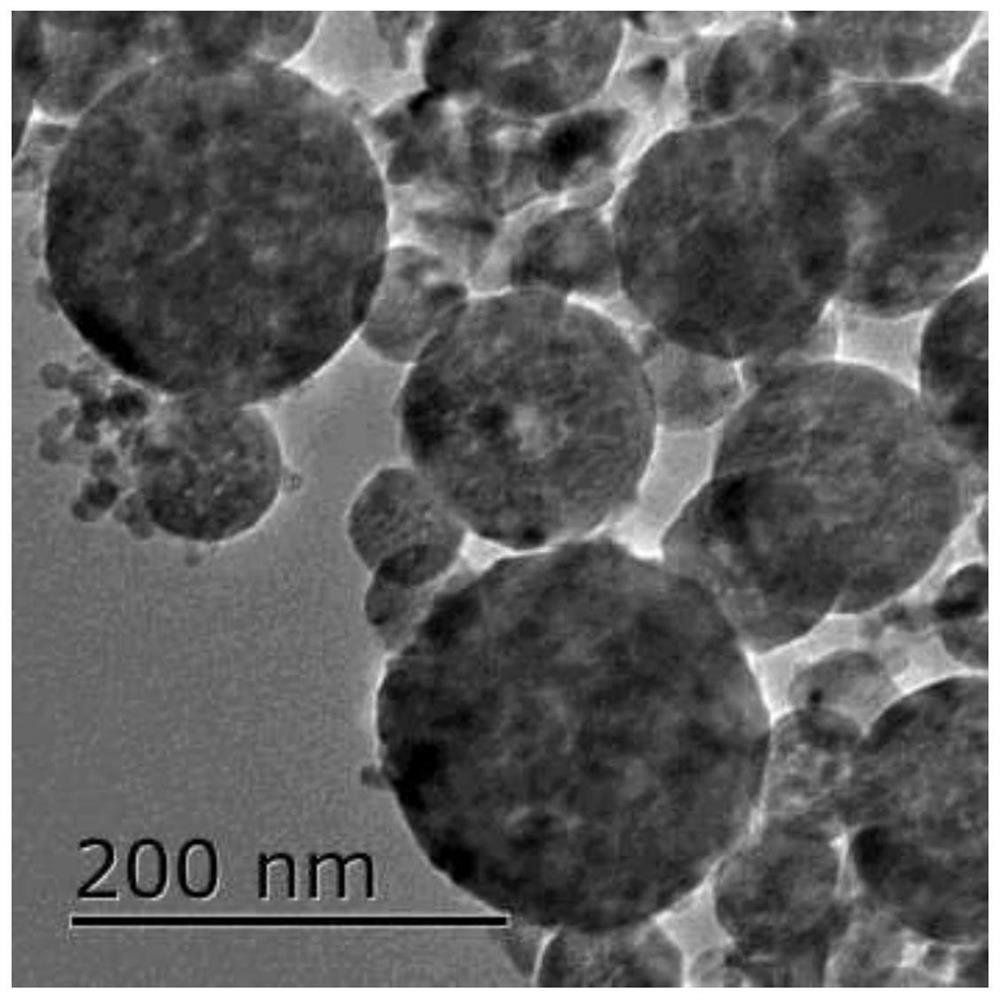

[0037] The transmission electron microscope figure of the product obtained in this embodiment is shown in figure 2 , it can be seen that the obtained product is spherical, with a particle size of 100 nm...

Embodiment 2

[0040] Preparation of nano-black TiO by an aerosol method 2 method, including the following steps:

[0041] Weigh 5g of titanium tetrachloride and 100g of absolute ethanol respectively and pour them into a beaker, and mix them uniformly by ultrasonic to obtain a homogeneous precursor solution; 2 As the carrier gas, and the carrier gas pressure is controlled to 0.3Mpa, the precursor solution is atomized into aerosol droplets through the atomizer, and then sent to a tube furnace at 700°C, and the reaction time is 0.9-1s to collect the obtained sample powder , that is, black TiO 2 nanoparticles.

[0042] The XRD pattern and TEM of the product obtained in this embodiment are shown in Figure 4 and Figure 5 . The results show that the obtained product is spherical TiO 2 particles.

Embodiment 3

[0044] Preparation of nano-black TiO by an aerosol method 2 method, including the following steps:

[0045] Weigh 10g of n-butyl titanate and 100g of n-hexane and pour them into a beaker, and mix them uniformly by ultrasonic to obtain a homogeneous precursor solution; 2 as the carrier gas, and the pressure of the carrier gas is controlled to 0.2Mpa. The precursor solution is atomized into aerosol droplets through the atomizer, and then sent to a tube furnace at 800°C for 1-2 seconds; the sample powder is collected to obtain Black TiO 2nanoparticles.

[0046] The XRD pattern and TEM of the product obtained in this embodiment are shown in Figure 6 and Figure 7 . The results showed that the obtained product was spherical TiO 2 particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap