A method for solid-liquid separation treatment of biogas slurry

A solid-liquid separation and treatment method technology, which is applied in the direction of centrifugal separation water/sewage treatment, extraction water/sewage treatment, waste fuel, etc., can solve the risk of aggravating the generation of dioxins in the biogas residue incineration process, limit sustainable promotion and application, Corrosion of biogas slurry treatment equipment, etc., to reduce the risk of secondary environmental pollution, overcome the large dosage of chemicals, and reduce the effect of SS in the effluent

Active Publication Date: 2022-05-31

TONGJI UNIV

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Furthermore, incineration has gradually become the development direction of solid waste final disposal in my country due to its significant benefits of reduction, stabilization, and energy conversion. However, the addition of polyaluminum chloride (PAC) and polyferric chloride (PFC) to The introduction of a large amount of chloride ions into the sludge aggravates the risk of dioxin formation in the biogas residue incineration process, Fe 3+ The introduction of biogas slurry treatment equipment will cause corrosion. The above defects seriously limit the sustainable application of traditional mixing / flocculation conditioners in biogas slurry solid-liquid separation + incineration process

In addition, for the biogas slurry solid-liquid separation process, quicklime is widely used as a coagulation conditioning agent, but the dosage usually reaches 10-15wt.% of the wet weight of the sludge, and the dosage is high, the capacity increase ratio is large, Adjusting the pH value of biogas slurry to alkaline has become the main factor that restricts the subsequent resource utilization and treatment efficiency of biogas slurry by traditional coagulation conditioners

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

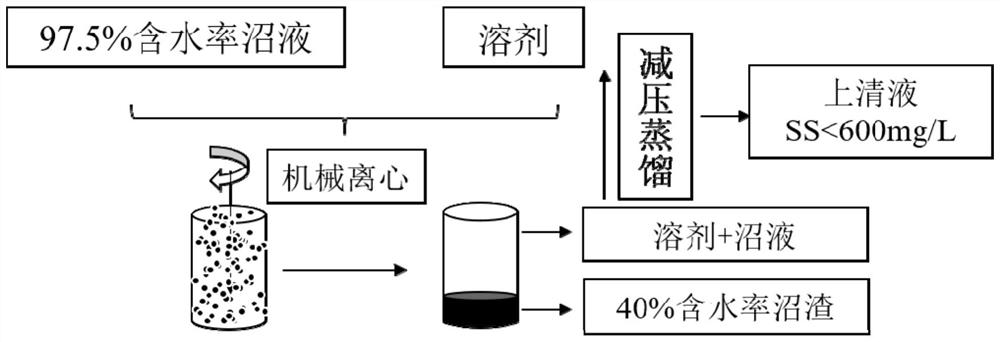

A method for solid-liquid separation of biogas slurry, using a conditioner to transfer some polar insoluble substances in the biogas slurry from the solid-liquid phase to the organic phase, thereby reducing the stability of the original colloidal system of the biogas slurry and improving the solid-liquid separation of sludge performance. Further, the conditioner is effectively recovered and recycled. It includes the following steps: mixing biogas slurry and conditioner, stirring and extracting reaction; separating solid and liquid from biogas slurry through mechanical centrifugation; realizing effective recovery of conditioner in supernatant and biogas residue after centrifugation, and then improving the solid content of biogas residue , Reduce the SS of the effluent and complete the recycling of the conditioner at the same time. Finally, the effluent SS can be lower than 600mg / L, the solvent recovery rate is more than 90%, and the moisture content of the mud cake is lower than 60%. The method reduces the consumption of coagulation / flocculation conditioning chemicals in the traditional biogas slurry solid-liquid separation process, and also reduces the energy consumption in the biogas residue incineration process, and has important social and environmental benefits and broad market application prospects.

Description

A kind of biogas slurry solid-liquid separation treatment method technical field Technical field Law. Background technique Biogas slurry is an inevitable product of organic food waste fermentation treatment, which carries a large number of pathogenic bacteria, heavy metals and poisons. Sexual organic pollutants, if not properly disposed of, will cause serious risks of environmental pollution. With the national garbage classification policy Vigorously promote, wet garbage is collected separately, because of its perishable and high water content, it is no longer possible to be the same as before. Other wastes are either sent to landfills for simple landfills, or sent to waste incineration plants for incineration. Therefore, a large amount of wet garbage is produced It poses a serious challenge to the prevention and control of environmental pollution and the sustainable utilization of social resources in my country, and fermentation technology is therefore widely us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F1/26C02F1/38

CPCC02F1/26C02F1/38Y02E50/30

Inventor 柴晓利戴晓虎汪浩武博然

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com