High-reliability tensioning wheel with asymmetric damping structure

A damping structure and reliability technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of low belt tension and uneven tension, achieve stable and uniform tension, clean and pollution-free environment, and ensure The effect of wear resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

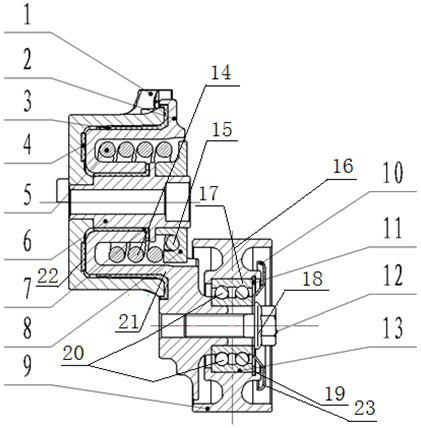

Image

Examples

Embodiment 1

[0021] A high-reliability asymmetrical damping structure tensioner provided by the present invention includes a support sleeve 1, a support plate 2, a support plate 2 21, a central shaft sleeve 6, a double-row deep groove ball bearing 20, a spring, and a cover plate 8 , Pulley one 16 and pulley two 9; Described support plate one 2 is provided with the hook groove one 5 that connects spring, and described support plate two 21 is provided with the hook groove two 14 that connects spring and the hook groove three 15, described The support plate one 2 is pressed on the support sleeve 1 by the spring compressed in the hook groove one 5, the cover plate 8 is pressed on the support plate by the spring compressed in the hook groove two 14, and the support plate two 21 is compressed by The spring in the hook groove three 15 is pressed on the support sleeve 1, and the two ends of the spring are respectively provided with hooks, one end of the spring is connected with the support plate on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com