Simulation test method for function of closing safety loop of sliding plug door of motor train unit

A safety loop, simulation test technology, applied in railway vehicle testing, circuit breaker testing, mechanical component testing, etc., can solve the problems of complex operation, long time to find fault doors, lack of etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

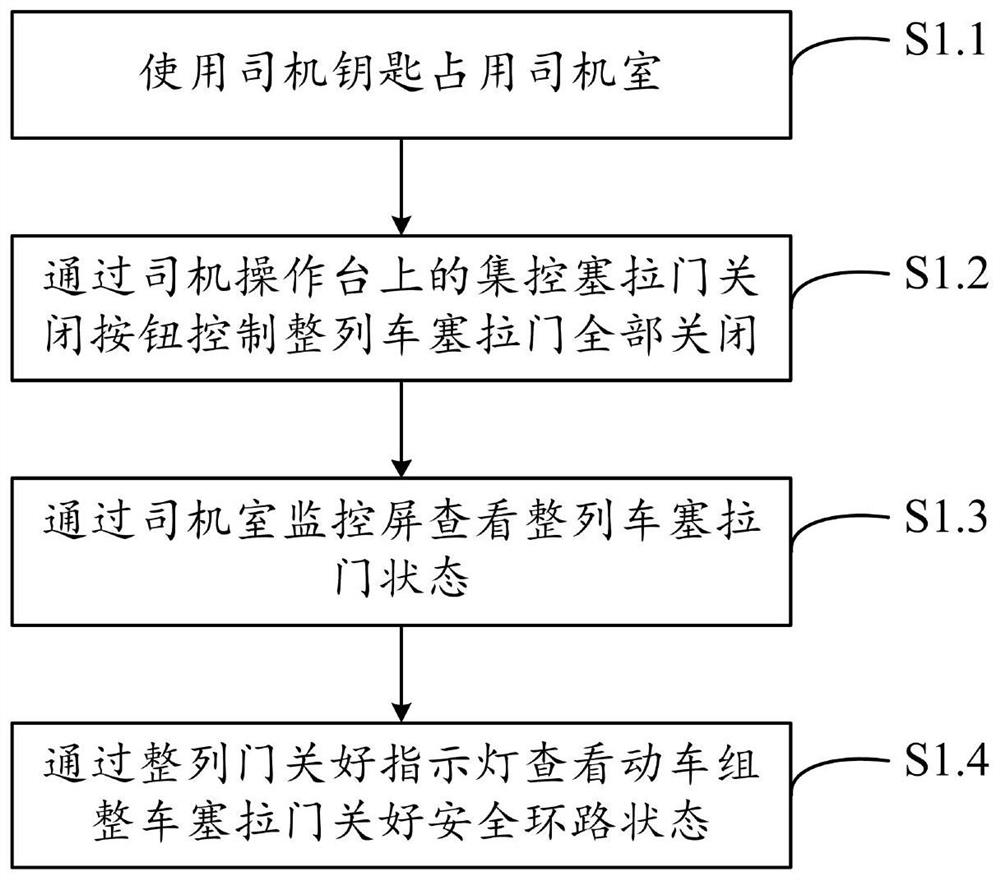

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

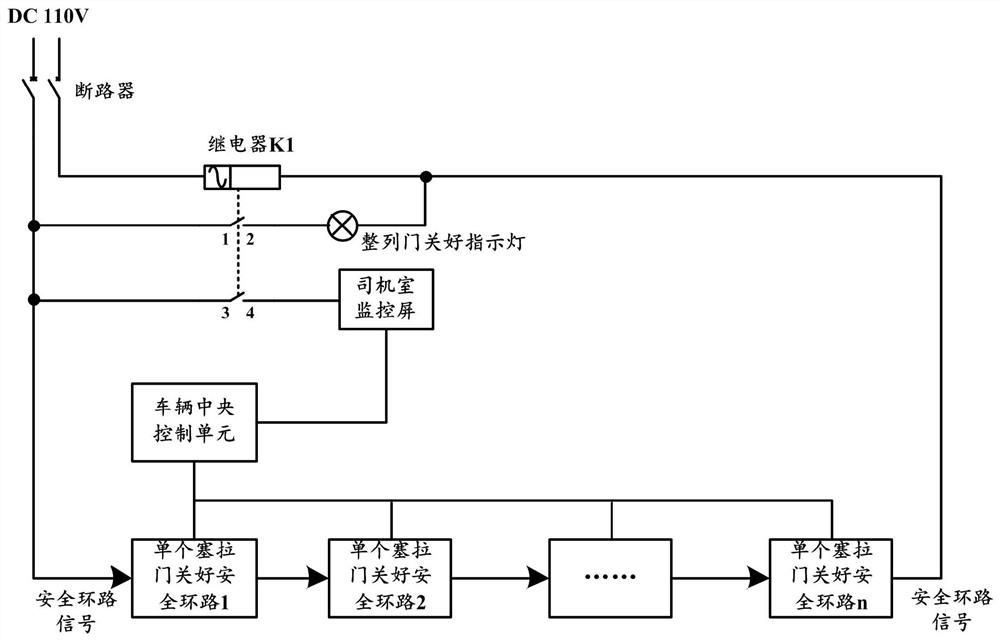

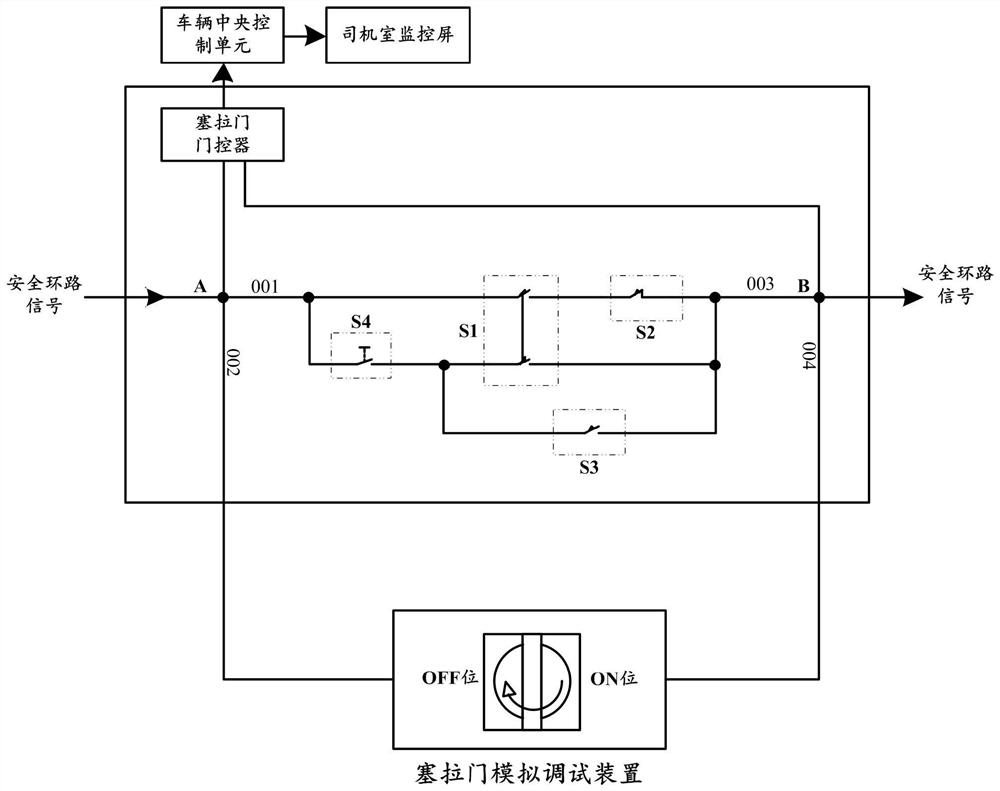

[0022] The simulation test method provided by the present invention is suitable for the function simulation test of the safety loop of the plug door of the EMU, wherein the safety loop of the plug door of the EMU includes the safety loop of the plug door of the whole vehicle of the EMU, The structure of the safety loop with the plug door closed for the entire train of the EMU is as follows: figure 1 As shown, it specifically includes the vehicle central control unit, the driver's cab monitoring screen (Human Machine Interface, HMI), the entire row of door closed indicator lights, circuit breakers, relay K1 and n series connected single plug door closed safety loops, etc. . The circuit breaker is connected with a 110V DC power supply (DC 110V), which is used to control the on-off of the safety loop signal of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com