Filling automatic wrapping production equipment and horizontal folding device

A technology of horizontal folding and folding devices, which is applied in the field of stuffing wrapping, which can solve the problems of reduced processing efficiency, slow manual operation speed, long residence time, etc., and achieve the effects of improving processing efficiency, avoiding residence time, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0035] This embodiment discloses a horizontal folding device for wrapping the filling skin 40 on the filling material 50, wherein the filling material 50 can be taro, pineapple, meat floss, etc., and the filling skin 40 can be oil skin, noodle skin, tofu Leather, etc., this application uses machines to replace manual work to obtain higher processing efficiency.

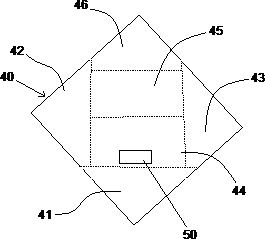

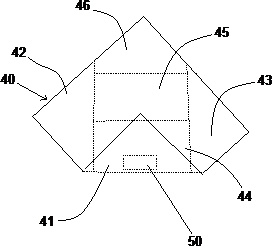

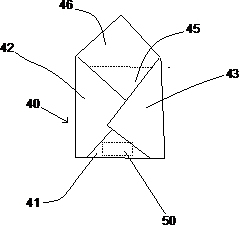

[0036] In traditional food processing processes such as spring rolls, pancakes, and taro rolls, the process of wrapping the filling 50 with the filling skin 40 generally includes: 1. Put the filling 50 on the filling skin 40 (see figure 1 ); 2. Fold the first part 41 of the filling crust 40 onto the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com