Transformation method for multi-metal ore dressing, grinding and classification process

A multi-metal and ore grinding technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low utilization factor of mills and low efficiency of classification equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

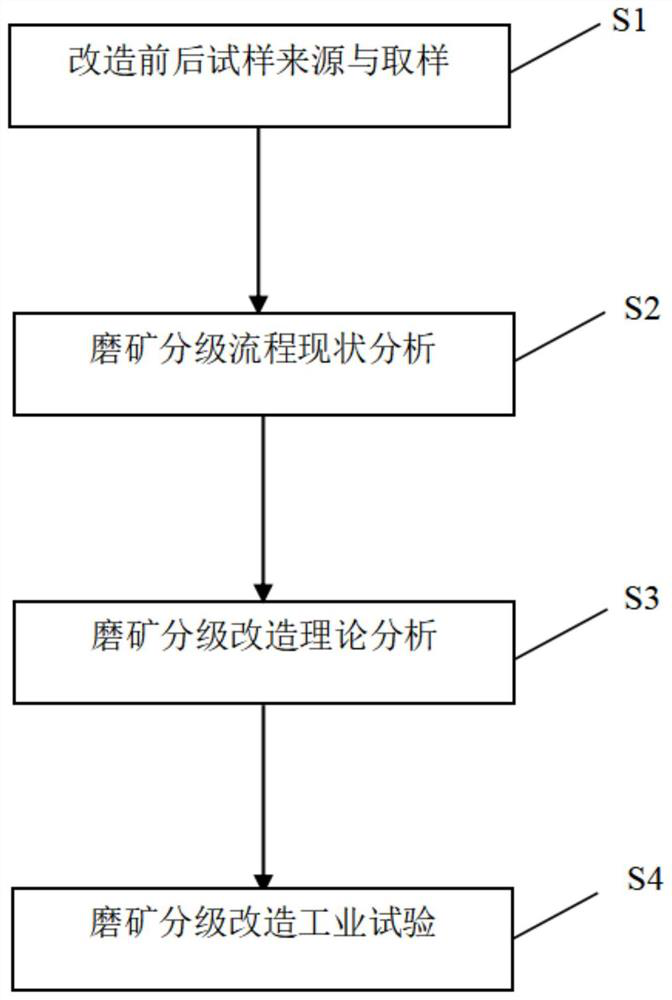

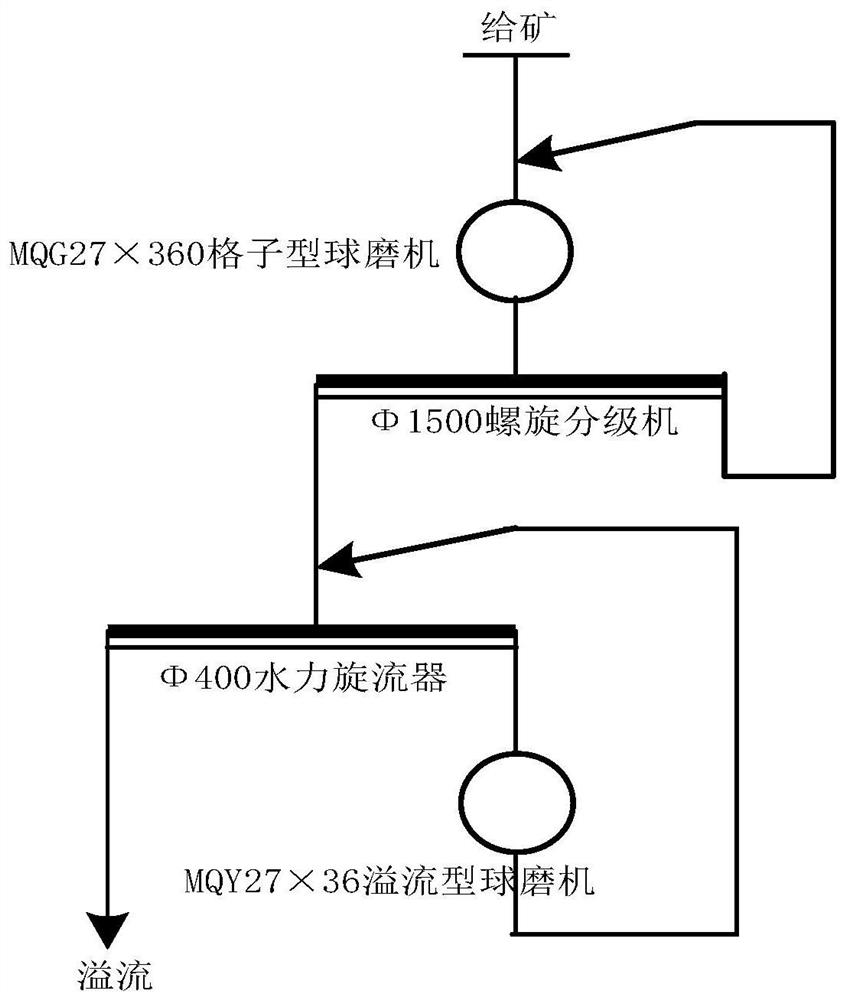

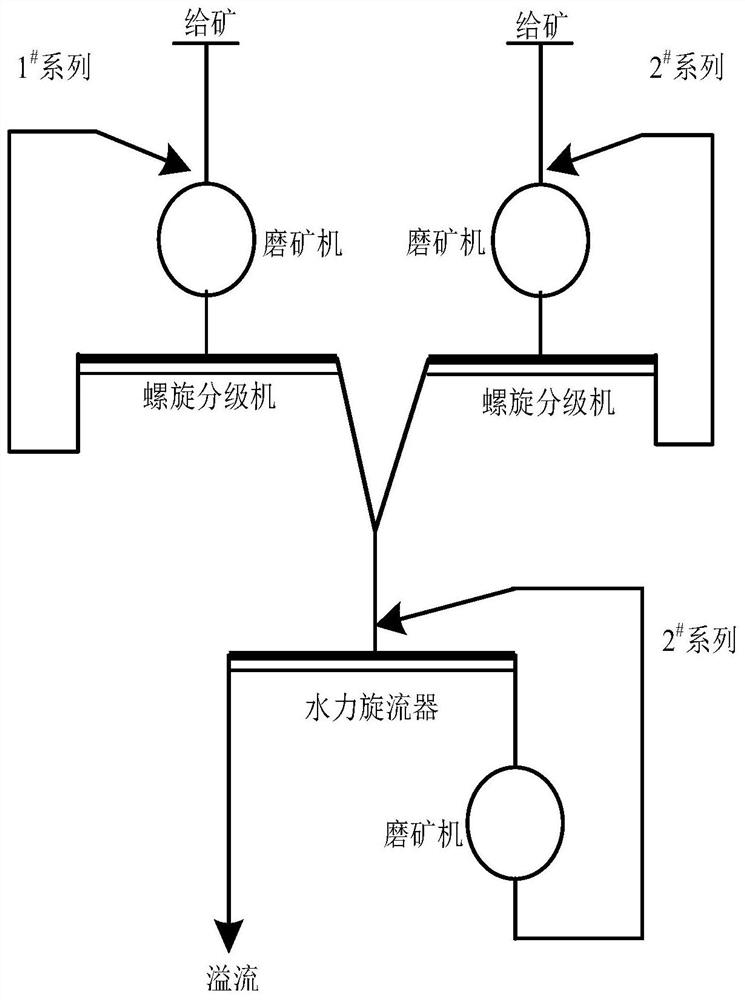

[0041] see Figure 1 to Figure 3 , the present invention provides a technical solution: a polymetallic mineral processing grinding classification process transformation method, comprising the following steps:

[0042] S1. Source and sampling of samples before and after transformation;

[0043] S2. Analysis of the status quo of the grinding and grading process;

[0044] S3. Theoretical analysis of grinding and classification transformation;

[0045] S4. Industrial test of ore grinding and grading transformation.

[0046] Step S1, sample source and sampling before and after transformation:

[0047] (1) Sampling points are arranged before transformation. Before tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com