A kind of beneficiation method of rare earth ore

A beneficiation method and rare earth ore technology, applied in flotation, solid separation, etc., can solve the problems of high chemical cost, toxicity, poor selectivity, etc., and achieve the effect of improving flotation recovery rate, good low temperature resistance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

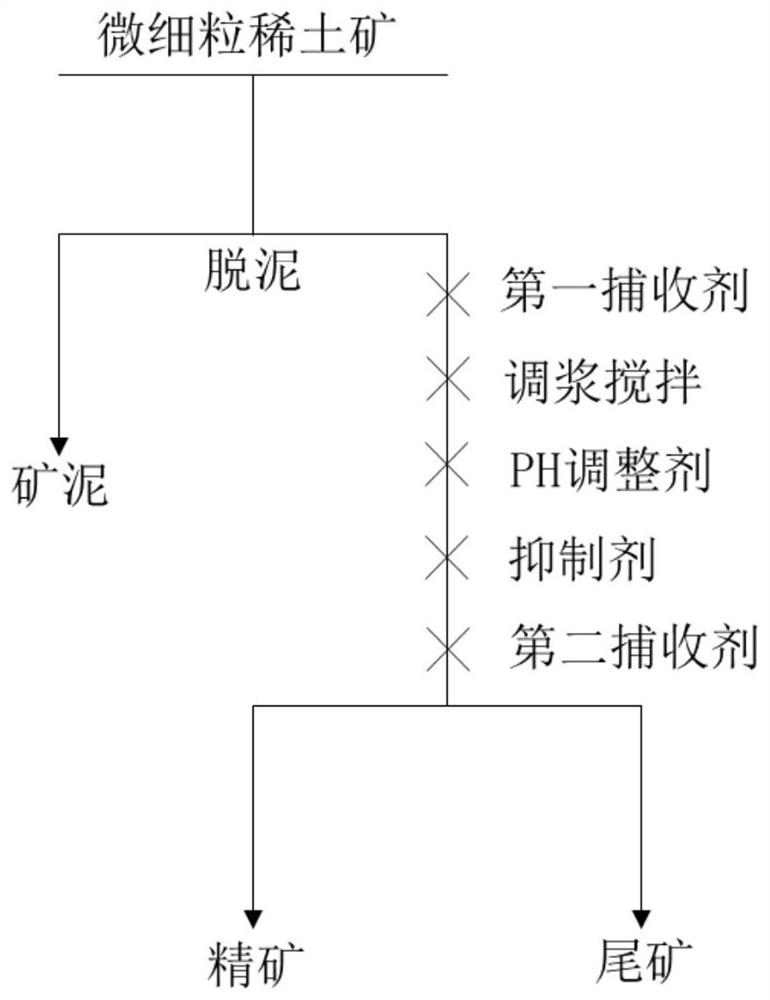

[0041]Embodiment 1 provides a kind of beneficiation method of rare earth ore, selects Shandong Weishan rare earth ore as ore sample to carry out flotation, comprises the following steps:

[0042] S1. Desliming: Desliming the micro-grained Shandong Weishan rare earth ore to remove -10 μm ore slime to obtain a fine-grained rare earth ore with a particle size of -30 μm+10 μm;

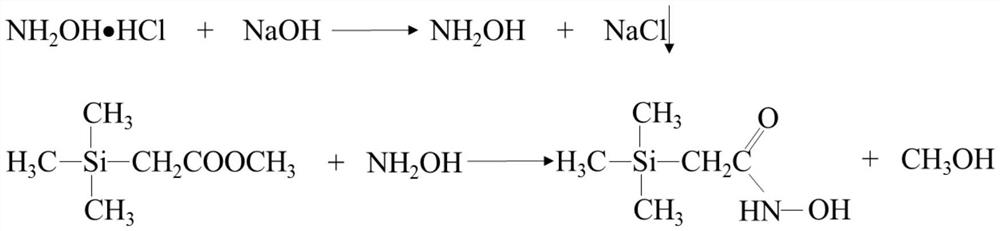

[0043] S2. Slurry: Add 450g / t of the first collector to the water, then adjust the fine-grained rare earth ore with a particle size of -30μm+10μm as described in step S1 to a concentration of 50%, and add sodium hydroxide to make the slurry The pH is controlled within 8.5-9.5, and the first mixture is obtained by stirring evenly; 700g / t hydroxyethyl cellulose is added to the first mixture, and the second mixture is obtained by stirring; the second collection of 650g / t is added to the second mixture Agent trimethylsilyl ethyl hydroxamic acid, stir to obtain the third mixture;

[0044] Described first colle...

Embodiment 2~8

[0051] The beneficiation method of the rare earth ore that embodiment 2~8 provides, compares with embodiment 1, and difference is that the addition amount of first collector, depressant and second collector is as shown in table 1, other and Embodiment 1 is basically the same and will not be repeated here.

Embodiment 9~14

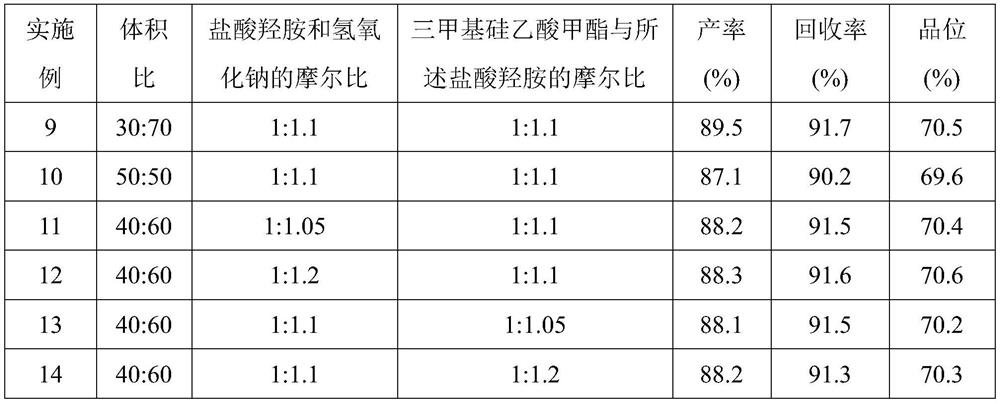

[0058] The beneficiation method of the rare earth ore that embodiment 9~14 provides, compared with embodiment 1, difference is that the volume ratio of dichloromethane and methanol, the molar ratio of hydroxylamine hydrochloride and sodium hydroxide and trimethylsilyl acetate methyl The molar ratio of the ester to the hydroxylamine hydrochloride is shown in Table 2, and the others are basically the same as in Example 1, and will not be repeated here.

[0059] The test result of preparation condition and productive rate, recovery rate and grade of table 2 embodiment 9~14

[0060]

[0061] As can be seen from Table 2, along with the increase of the volume ratio of dichloromethane and methanol, the productive rate of trimethylsilyl ethyl hydroxamic acid gradually decreases, and the recovery rate and grade of rare earth ore also decrease correspondingly, indicating that Too low methanol content is unfavorable for the reaction to proceed. Within the limits of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com