Leakage-proof device for muck transportation

A leak-proof device and muck technology, applied in the directions of transportation and packaging, packaging, containers, etc., can solve problems such as cumbersome and environmental pollution, and achieve the effects of avoiding impact, reducing cleaning difficulty, and preventing falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

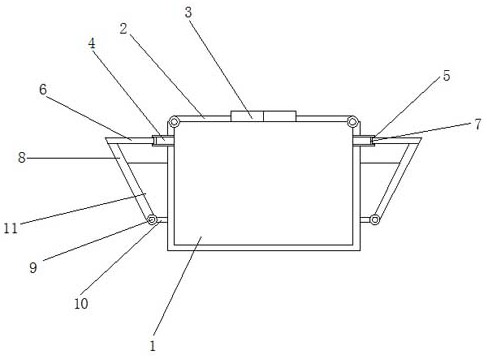

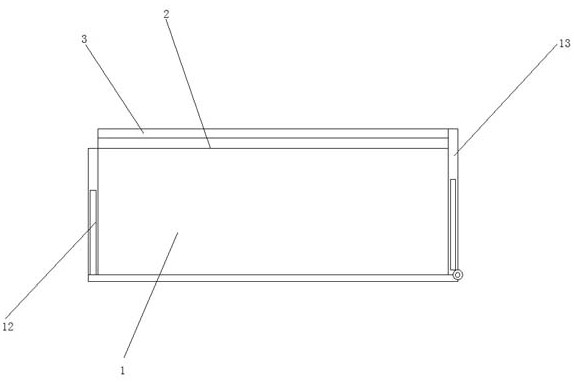

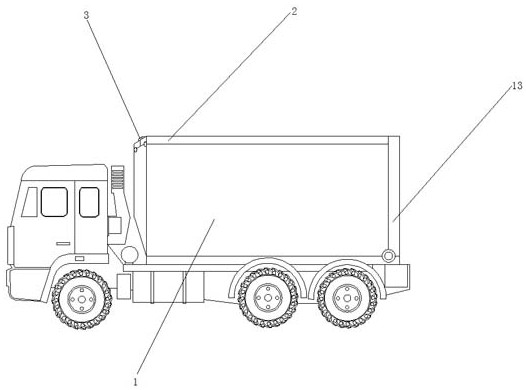

[0019] Embodiment 1, with reference to Figure 1-3 , a leak-proof device for muck transportation, comprising a compartment 1, a cover plate 2 is provided on the outer walls on both sides of the top of the compartment 1, and a sealing plate 3 is welded on one side outer wall of the cover plate 2, when the muck is transported In the process, due to the unevenness of the road surface, the muck truck will bump when driving, which will cause the muck to fall and affect other vehicles on the road. At the same time, it is time-consuming and laborious to clean up. 3. The muck packed in the carriage can be sealed, and at the same time, it can also ensure that it will not be overloaded during transportation, prevent the muck from falling when bumping, avoid the impact of the muck on the ground, and reduce the difficulty of cleaning;

[0020] The upper part of the outer wall on both sides of the compartment 1 is welded with a sliding tube 4, and the inner wall of one side of the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com