Waste bin with side-rotating cover

A technology of waste buckets and rotating lids, which is used in trash cans, garbage collection, household appliances, etc., can solve the problems of polluting the surrounding environment and air overflow, and achieves the effect of good sealing effect, reducing occupied space and avoiding overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

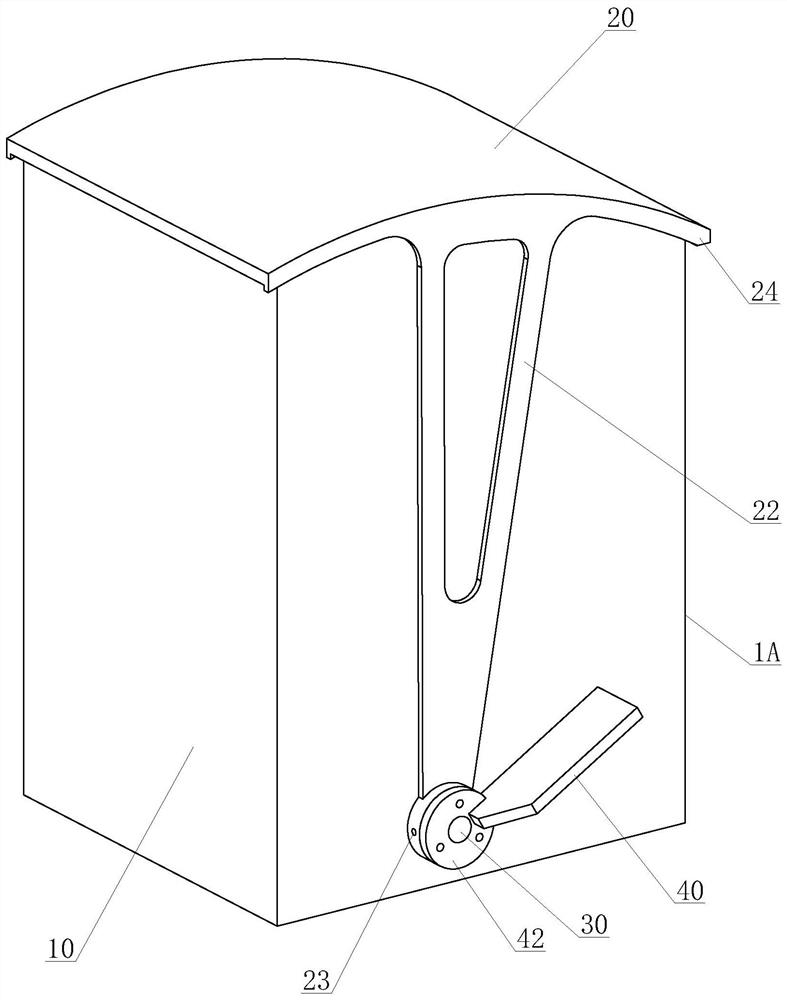

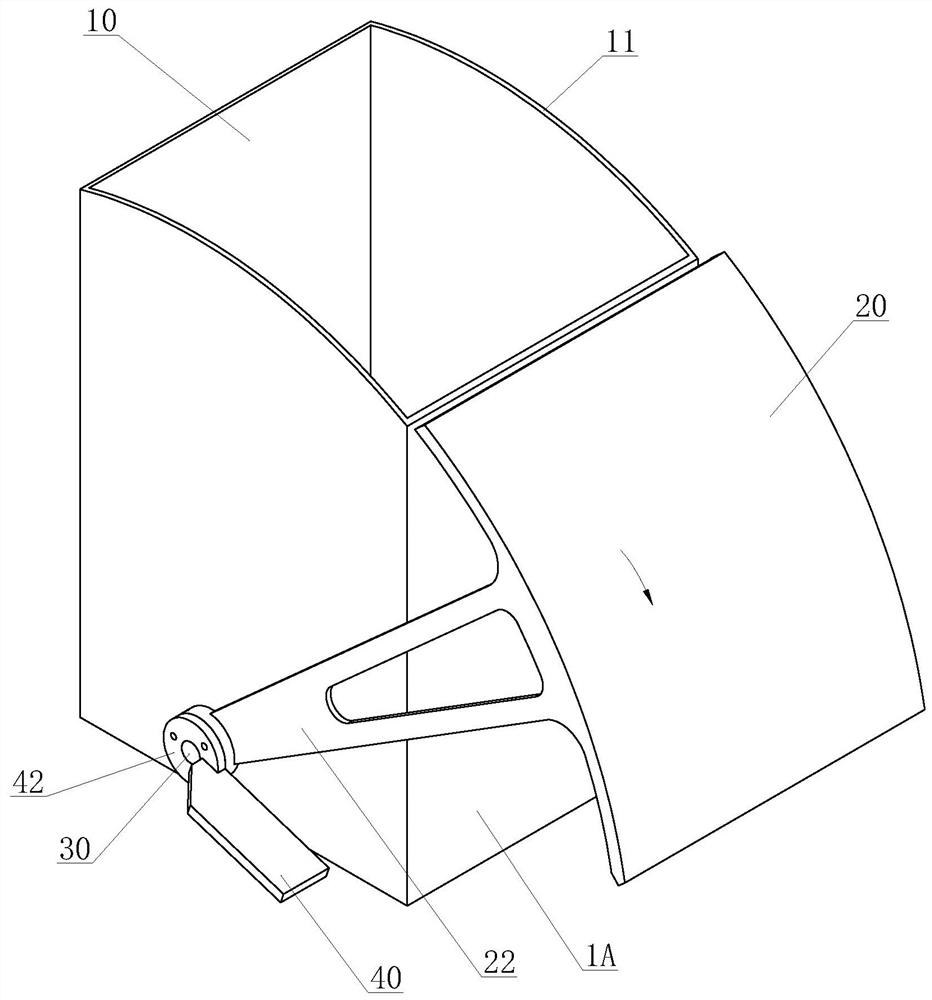

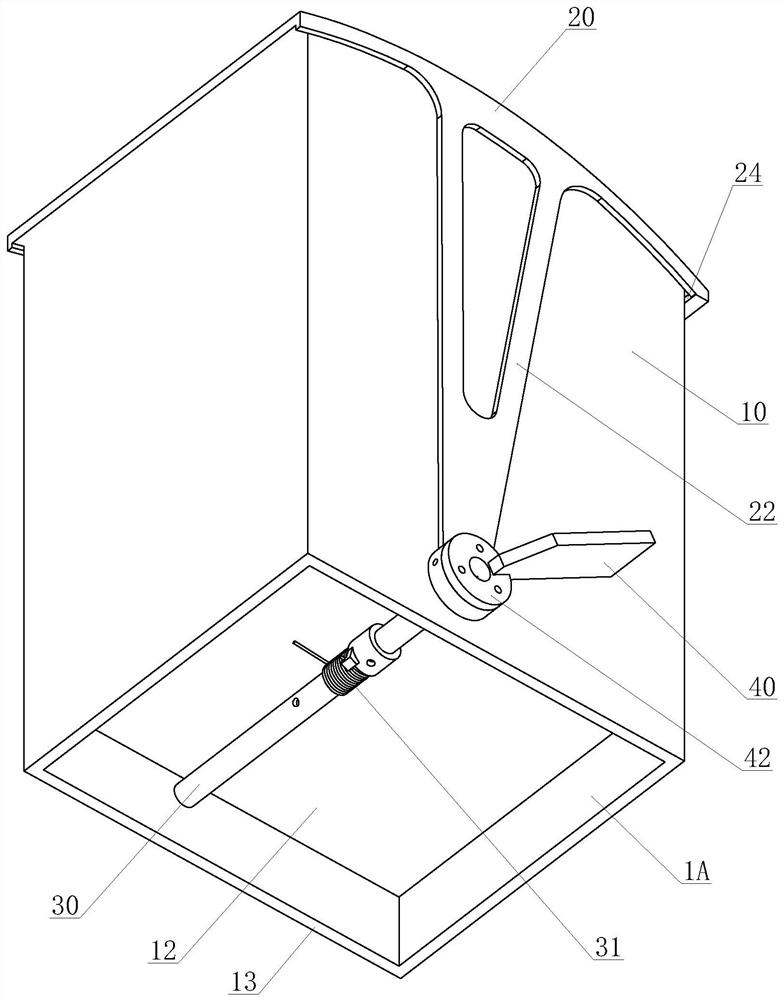

[0038] Such as Figure 1 to Figure 6 , a waste bin with a side rotating lid, comprising a barrel body 10, the upper port of the barrel body is provided with a side rotating lid 20.

[0039] The barrel body 10 is a rectangular barrel body with an open upper end. One side of the barrel facade is the opening side 1A of the barrel lid, and the bottom surface 12 of the barrel body is higher than the lower edge 13 of the barrel body to accommodate parts such as the barrel lid rotating shaft. The port 11 on the barrel body is an arc-shaped port, and the arc center C1 of the port on the barrel body is reversely offset to the opening side of the barrel lid, ie. The distance L1 from the arc center C1 to the opening side 1A of the bung is greater than one-half of the length L of the bung, which can reduce the external space K occupied when the side rotation bung is opened (such as Figure 6 shown).

[0040] The bottom of the barrel body is provided with a bung lid rotating shaft 30, a...

Embodiment 2

[0047] Such as Figure 7 , Figure 8 , a waste bin with a side swivel cover. This embodiment is an improvement of the first embodiment.

[0048] In this embodiment, a sealing plate 21 is provided on the inner side of the side rotating bung. The sealing plate 21 is in the shape of a circular arc corresponding to the upper port 11 of the barrel (also an arc corresponding to the side rotating bung). Plate 21 closes the upper port of the staving.

[0049] The sealing plate is elastically connected with the side rotating barrel cover. In this embodiment, the sealing plate is connected with the side rotating bucket lid through four spring pieces 25 . Four leaf springs connect the sealing plate and the side rotating bung by rivets 26 (or screws). The sealing plate presses the upper end of the bucket body through elastic pressing in the closed position of the side-rotating bucket cover.

[0050] In order to control the position of the sealing plate 21 relative to the port 11 on ...

Embodiment 3

[0053] Such as Figure 9 to Figure 13 , a waste bin with a side swivel cover. This embodiment is an improvement of the first embodiment.

[0054] In this embodiment, the pedal 40 is provided with a shaft hole 43, and the side rotating bucket cover is provided with a shaft head 28. The pedal 40 is connected to the shaft head 28 through the shaft hole 43, and the pedal is pressed on the shaft of the bucket cover through a retaining ring 44 and a screw 45. On, that is, the pedal can rotate relative to the bung shaft and the side-rotating bung, instead of rigidly driving the side-rotating bung to rotate.

[0055] A driving spring 41 is arranged between the pedal and the side rotating bucket cover. The driving spring 41 is a spring bar. The pedal drives the side rotating bucket cover 20 to rotate through the driving spring 41. When the pedal 40 is stepped on, the driving spring 41 will produce proper bending. Thereby, the side rotary bucket cover is driven to rotate in an elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com