Encapsulating equipment capable of passing materials along tangent plane path of rotary powder disc

A section and path technology, applied in the manufacture of encapsulation/enclosure resistors, circuits, encapsulated capacitor devices, etc., can solve the problems of inability to evenly encapsulate, consume large amounts of energy, and cannot be connected, and achieve better encapsulation effects. The effect of avoiding powder and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

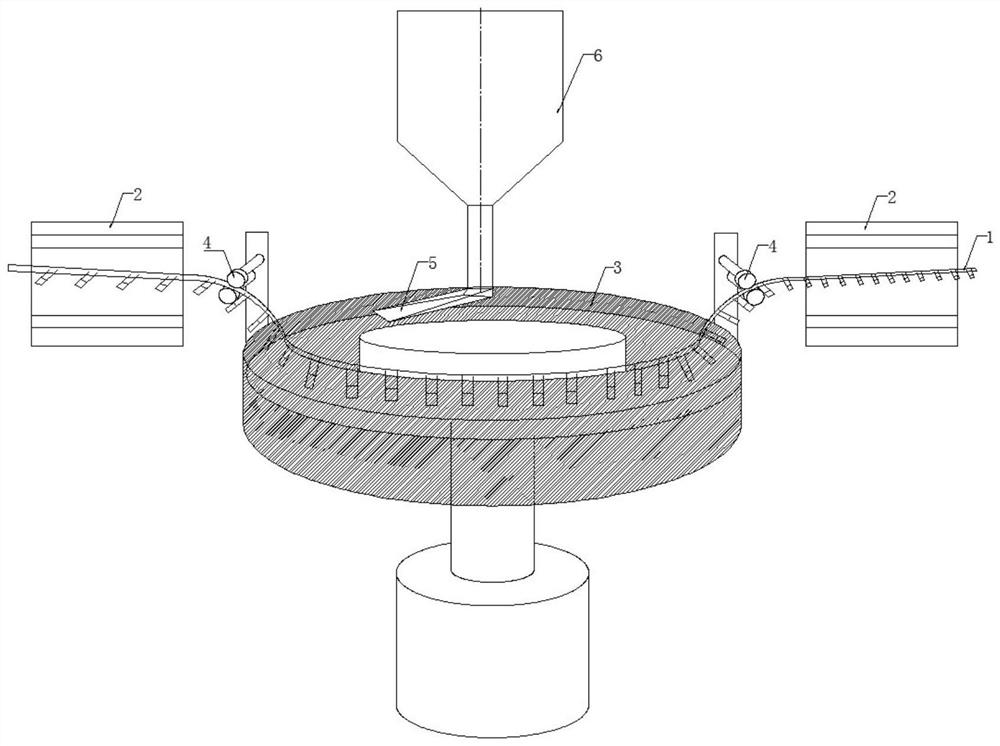

[0016] The present invention will be described in further detail below with reference to the accompanying drawings.

[0017] refer to figure 1 As shown in the figure, an encapsulation device that feeds materials along the cutting surface path of the rotating powder disc has a material belt 1 pulled by a traction mechanism, a heating mechanism 2 and an annular powder groove 3 driven by a motor. Arrange the parts to be encapsulated. The parts to be encapsulated are electronic components with two pins and chips welded at the end, such as thermistors, varistors, ceramic capacitors, etc., and the pins of the electronic components are glued by adhesive tape Attached to the material belt 1, the material belt 1 can be advanced by unwinding and rewinding traction. After being heated by the heating mechanism 2, it enters the ring-shaped powder tank 3 to deposit insulating powder to form an insulating layer.

[0018] Specifically, the two sides above the annular powder trough 3 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com