Garbage can capable of achieving dry-wet separation and automatic lid opening

A technology of automatic lid opening and wet and dry separation, applied in the field of trash cans, can solve the problems of people's discomfort, contamination of waste liquid, and hand contamination of waste liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

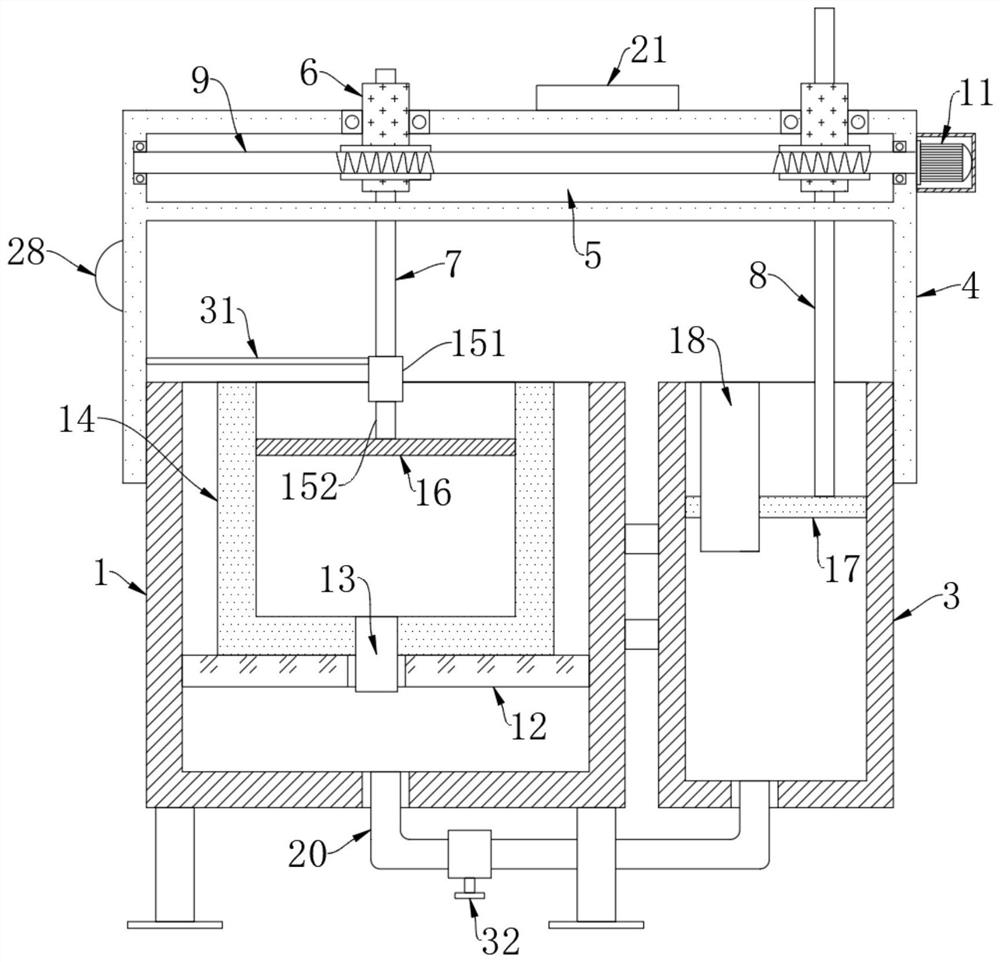

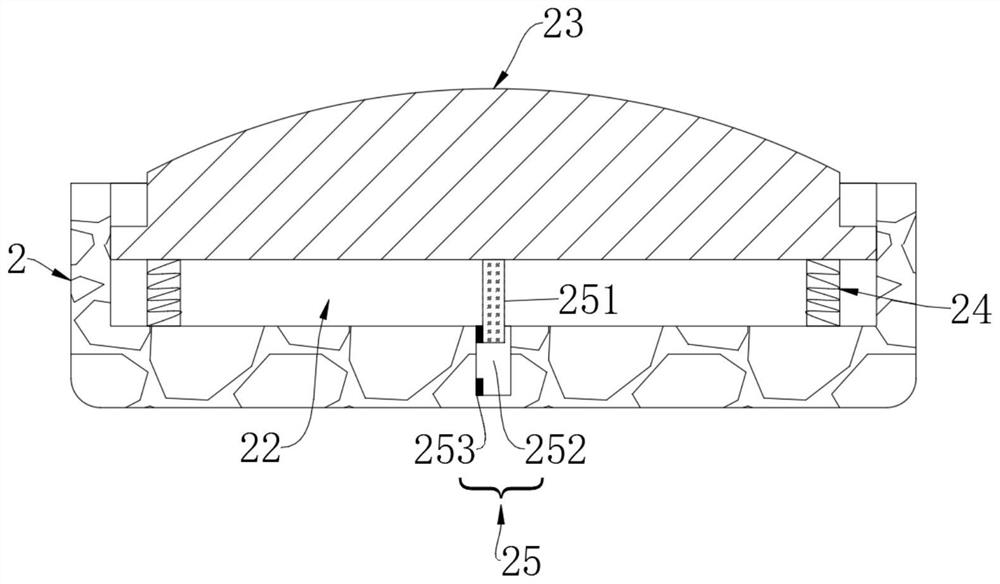

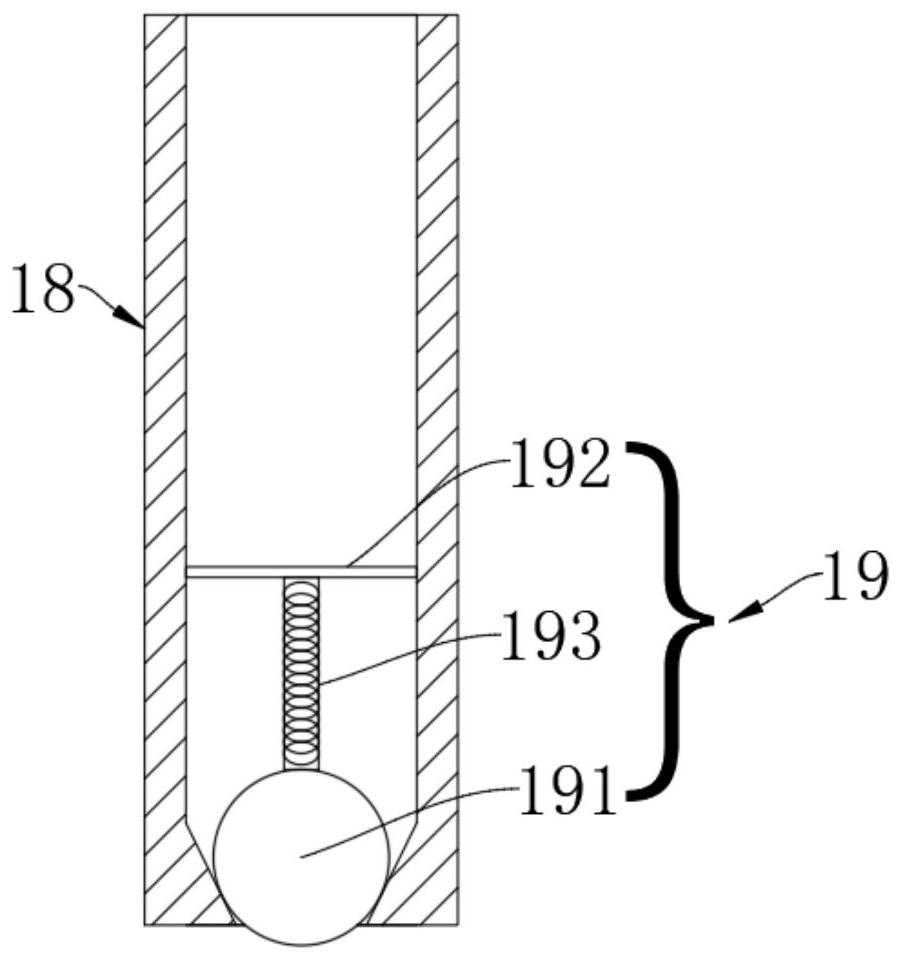

[0024] Such as Figure 1-7 As shown, a trash can that can realize dry-wet separation and automatic lid opening includes a barrel body 1, the barrel body 1 is fixedly connected with a transmission floor 2, and one side wall of the barrel body 1 is fixedly connected with a liquid collection barrel 3, and the barrel body 1 is fixedly connected with a liquid receiving barrel 3, A support 4 is fixedly connected between the body 1 and the liquid receiving barrel 3, and a transmission cavity 5 is provided on the support 4. Two threaded sleeves 6 are rotatably connected to the transmission cavity 5, and the first screw rods are threaded in the two threaded sleeves 6 respectively. 7 and the second screw 8, the two threaded sleeves 6 are sleeved with a worm wheel 9, the transmission cavity 5 is connected with a worm 10 in rotation, and the worm 10 is engaged with the worm wheel 9, and the worm 10 is provided with two sections with opposite directions of rotation. screw thread, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com