Environment-friendly coating printing machine

A printing press and coating technology, applied in printing presses, rotary presses, printing and other directions, can solve problems such as insufficient to overcome the deflection force of the cloth, difficulty in achieving rapid deflection correction, and wavy damage to the cloth, so as to avoid corrective failure, The effect of eliminating faults and preventing the deviation of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

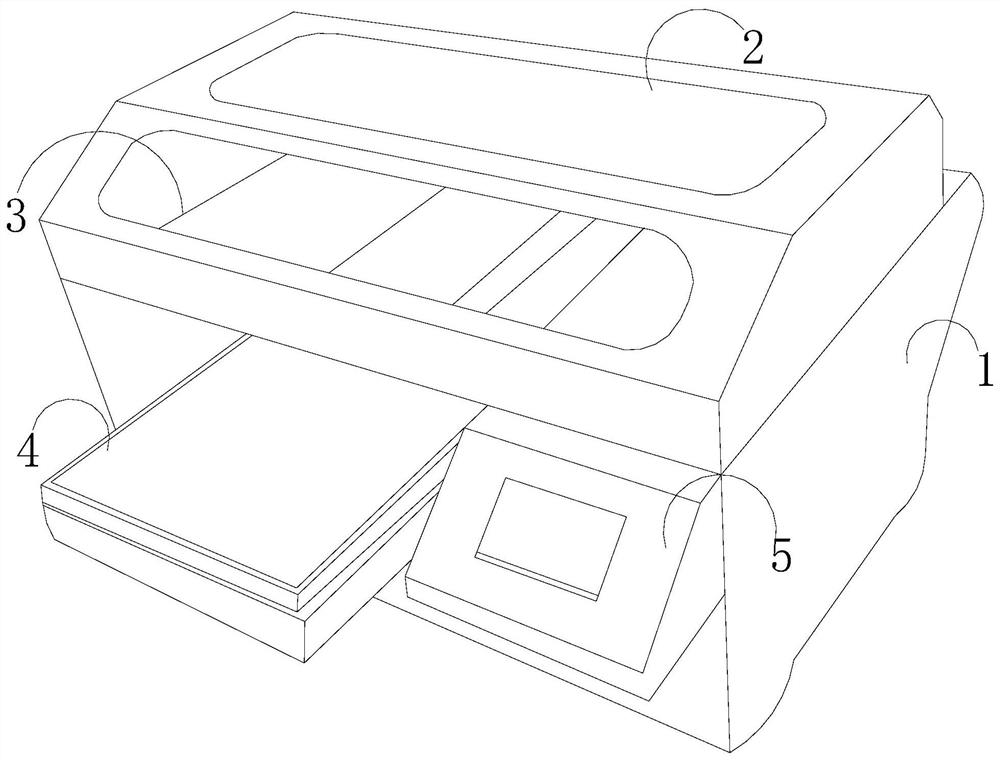

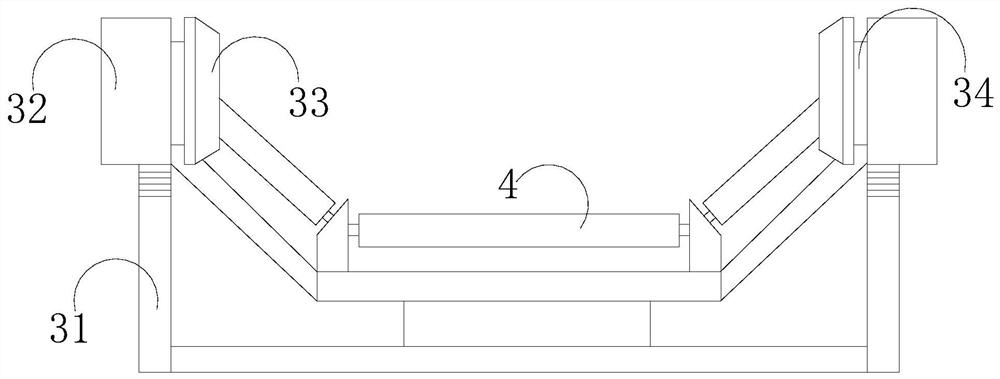

[0029]Such asFigure 1-Figure 3 As shown, the present invention provides an environmentally friendly coating printer, which structure includes a housing 1, an upper inspection port 2, a correction device 3, a printing platform 4, and a control panel 5. The outer surface of the housing 1 is equipped with a control panel 5 With the upper inspection port 2, the control panel 5 is electrically connected to the correcting device 3 inside the housing 1. The correcting device 3 is arranged on both sides of the printing platform 4, and the correcting device 3 includes a mechanism seat 31. The driving member 32, the supporting roller carrier 33, and the boosting device 34, the mechanism seat 31 is fixedly connected with the driving member 32, and the groove position surface of the supporting roller carrier 33 is movably clamped on both ends of the printing platform 4 A boosting device 34 is installed between the driving member 32 and the supporting roller carrier 33. The boosting device 34 in...

Embodiment 2

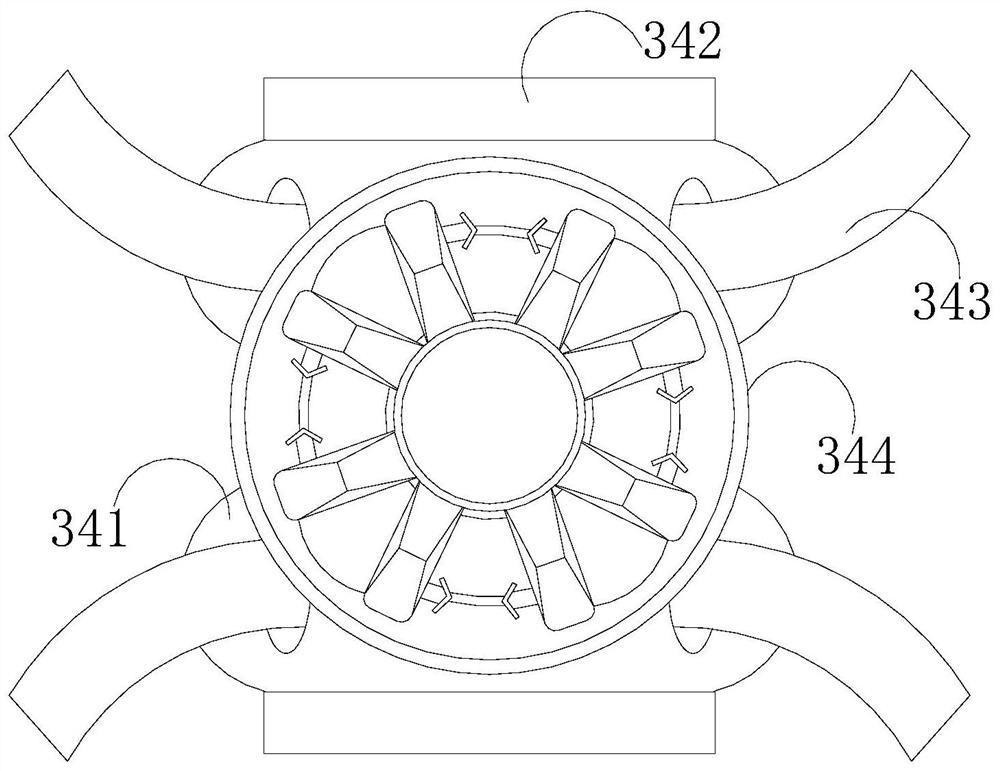

[0031]Such asFigure 4-Figure 6As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The grip structure 343 includes an anti-falling ring 431, a running-in block 432, a torsion-resistant connecting strip 433, and a suction pad 434. The running-in block 432 transitionally fits with the suction pad 434 through the torsion-resistant connecting strip 433. The torsion connecting strip 433 has three suction pads 434 with the same structure and different sizes. The cross section formed between the torsion-resistant rod 433 and the suction pad 434 is a stepped structure. The positioning device 344 includes a slide 441, an opening and closing device 442, an expansion fan 443, a connecting column 444, A sliding block 445 and a supporting ring 446. An opening and closing device 442 is installed on the slide 441. A supporting ring 446 is fixedly connected between the upper part of the opening and closing device 442 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com