A combined oilfield water injection well layered acidification device

An oil field water injection, combined technology, applied in wellbore/well components, construction, earth-moving drilling, etc., can solve the problems of not distinguishing the clogging of sand control pipes, different times of acidizing and unblocking, insufficient unblocking time, etc. The effect of maximum utilization, reduction of acidification time, and extension of acidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

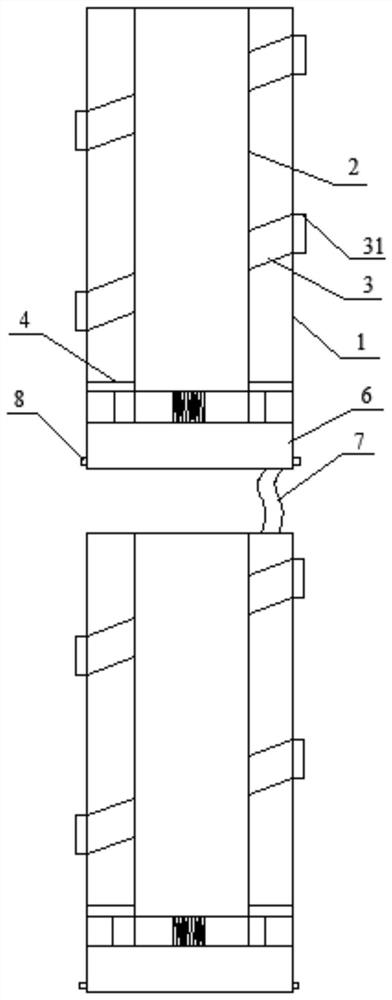

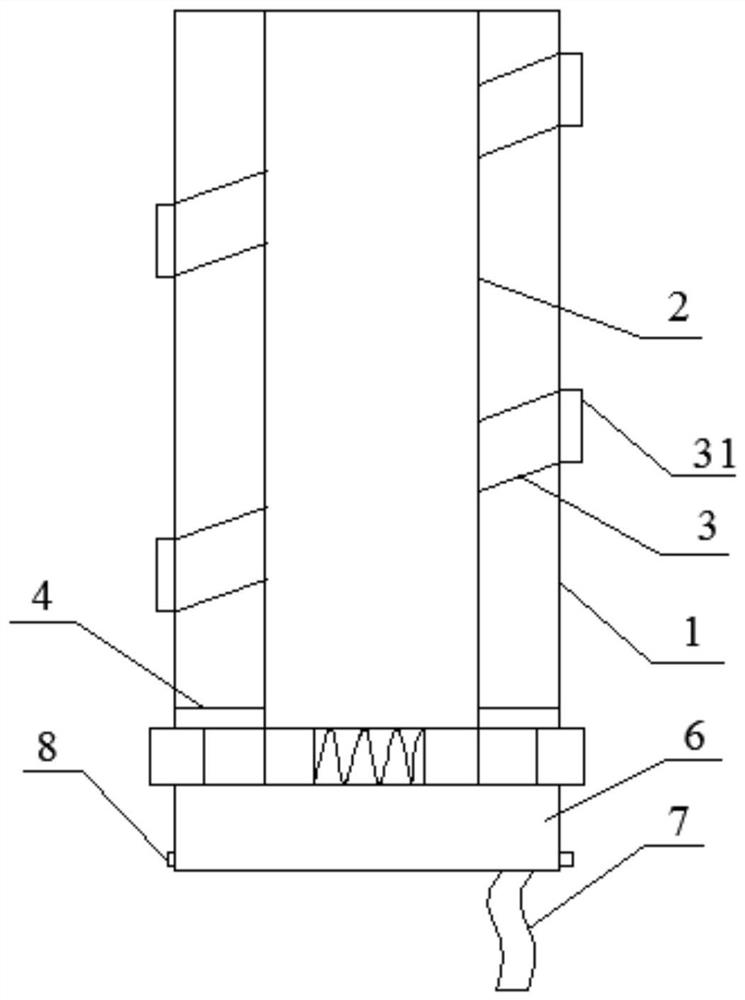

[0047] A combined oilfield water injection well layered acidification device, such as Figure 1-4 As shown, it includes several acidizing units, and the adjacent acidizing units are detachably connected. These acidizing units are used to be positioned at different formation heights in the sand control pipe in the oilfield water injection well. They can be connected and used, or they can be distributed discretely in the sand control pipe It is used in order to achieve the plugging effect of sand control pipes at different formation heights, with strong pertinence and high efficiency, and it can also save acidizing fluid.

[0048] The acidizing unit includes: an outer pipe 1, which is used to be positioned at a specific formation height in the sand control pipe in the water injection well of the oil field, and an inner pipe 2 is coaxially sleeved inside the outer pipe 1, and the outer pipe 1 and There is a cavity between the inner pipes 2 where the acidizing liquid injection pip...

Embodiment 2

[0057] A combined layered acidification device for water injection wells in oilfields, the structure of which is basically the same as that of Example 1, the difference is that the telescopic air bag 51 is provided with a number of micropores, and the interior of the telescopic air bag 51 is filled with water-absorbing materials, which are sprayed onto sand control The excess acidizing liquid on the pipe flows into the water-absorbing material along its inner wall and is absorbed to prevent excessive acidizing liquid from stagnating in the formation. The water-absorbing material chooses a material with physical adsorption effect, which can analyze and recover the acidizing liquid and achieve the effect of resource recycling. For example, the sponge material can absorb water and squeeze water out.

[0058] There is also a distance of 0-2 mm between the connecting rigid pipe 6 and the positioning assembly, so as to receive excess acidizing fluid leaking from the telescopic air ba...

Embodiment 3

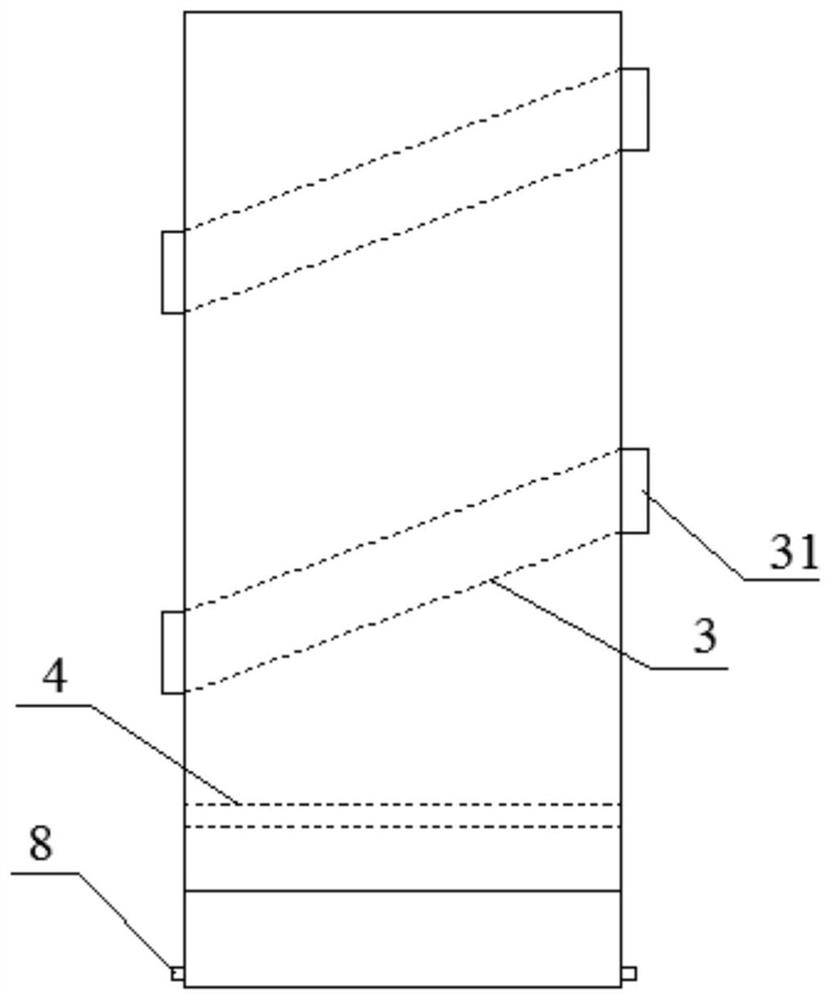

[0060] A combined layered acidification device for oilfield water injection wells, basically the same structure as in Example 1, the difference is that the structure of the positioning assembly is as follows Figure 5 As shown, it includes an electric telescopic rod 5, an inner telescopic ring and an outer telescopic ring that are sequentially sleeved from the inside to the outside. The inner telescopic ring is surrounded by several inner arc-shaped plates 52, and the outer telescopic ring is surrounded by several outer arc-shaped plates 53. The electric telescopic rod 5, the inner arc-shaped plates 52, the outer The number of arc-shaped plates 53 is the same, and they correspond to each other. The positions of the inner arc-shaped plate 52 and the outer arc-shaped plate 53 correspond radially, the fixed end of the electric telescopic rod 5 is fixedly installed on the outer wall of the inner tube 2, and the movable end is fixedly installed on the corresponding The inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com