High-precision detection device for transmission errors of gearbox

A technology of transmission error and detection device, which is applied in the field of measurement and control, can solve expensive problems and achieve the effects of low cost, high precision and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

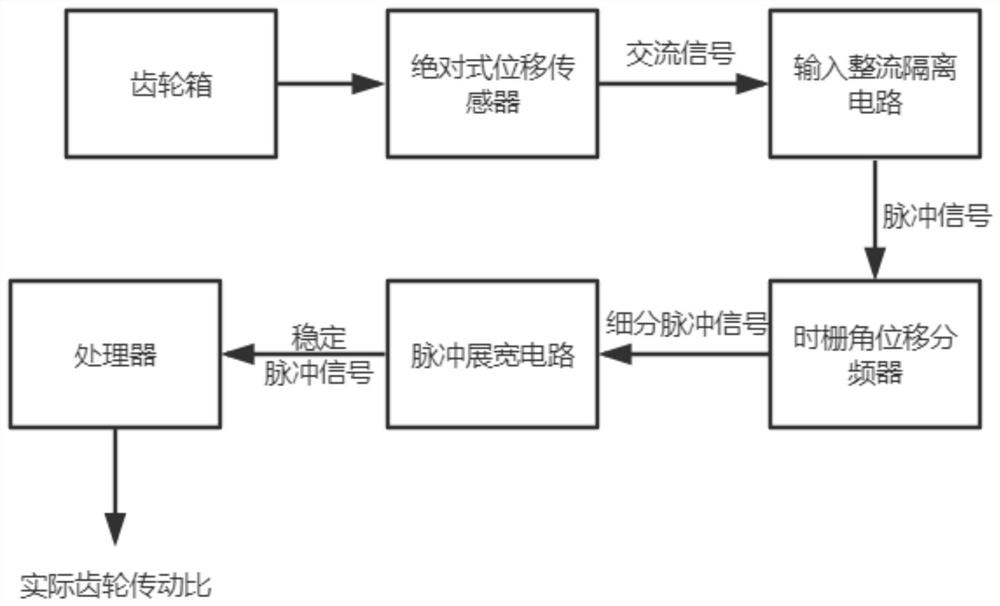

[0016] Please refer to figure 1 , a high-precision detection device for gearbox transmission errors, comprising the following:

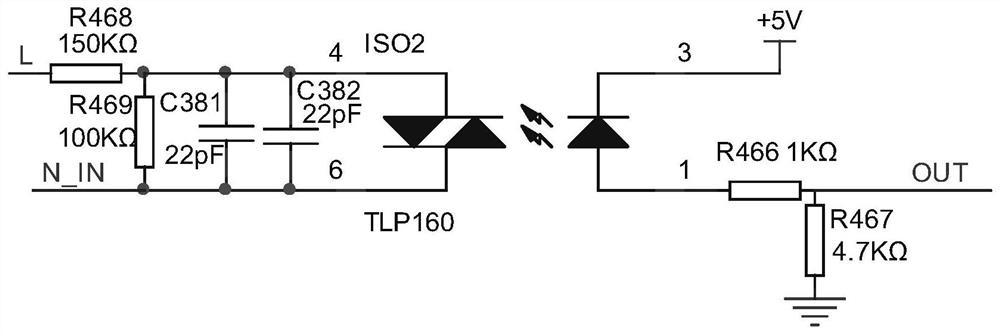

[0017] Processor, absolute displacement sensor, input rectification isolation circuit, time grid angular displacement frequency divider and pulse stretcher circuit;

[0018] The absolute displacement sensor is electrically connected to the input rectification isolation circuit; the input rectification isolation circuit is electrically connected to the time grid angle displacement frequency divider; the time grid angle displacement frequency divider is connected to the pulse The stretcher circuit is electrically connected; the pulse stretcher circuit is electrically connected to the processor;

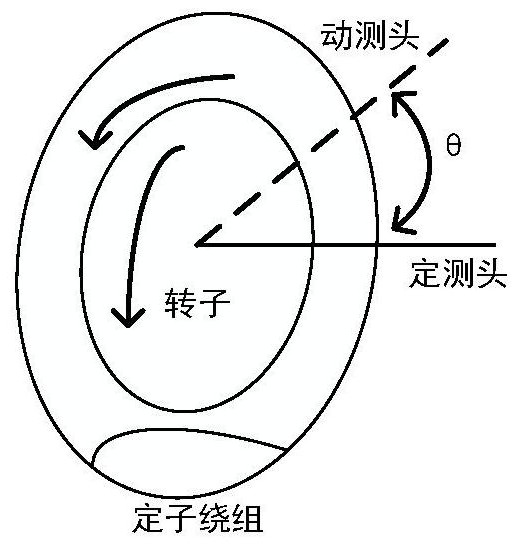

[0019] The absolute displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com