A train battery on-line monitoring system

A monitoring system and battery technology, applied in the measurement of electricity, heat, measurement devices, etc., can solve the problems of rapid heating or even combustion and explosion, battery failure, increased maintenance and repair workload, etc., to achieve real-time operation data record storage and traceability analysis, the effect of reducing power supply system failures and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

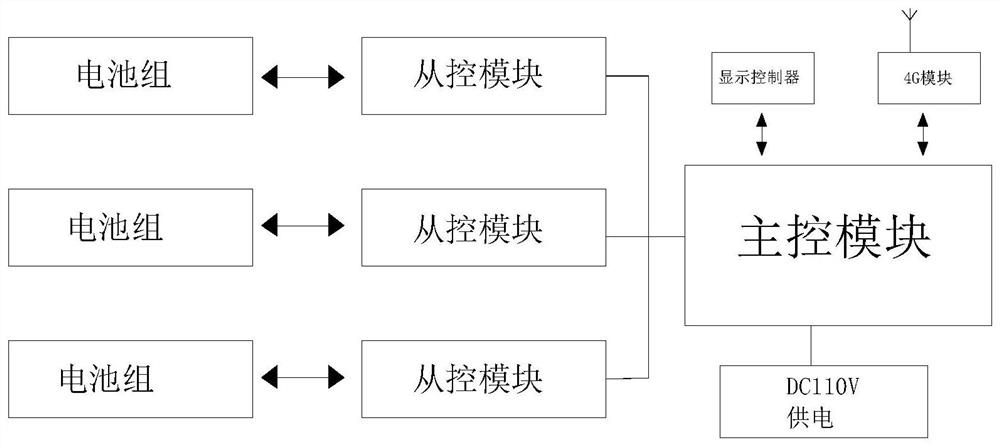

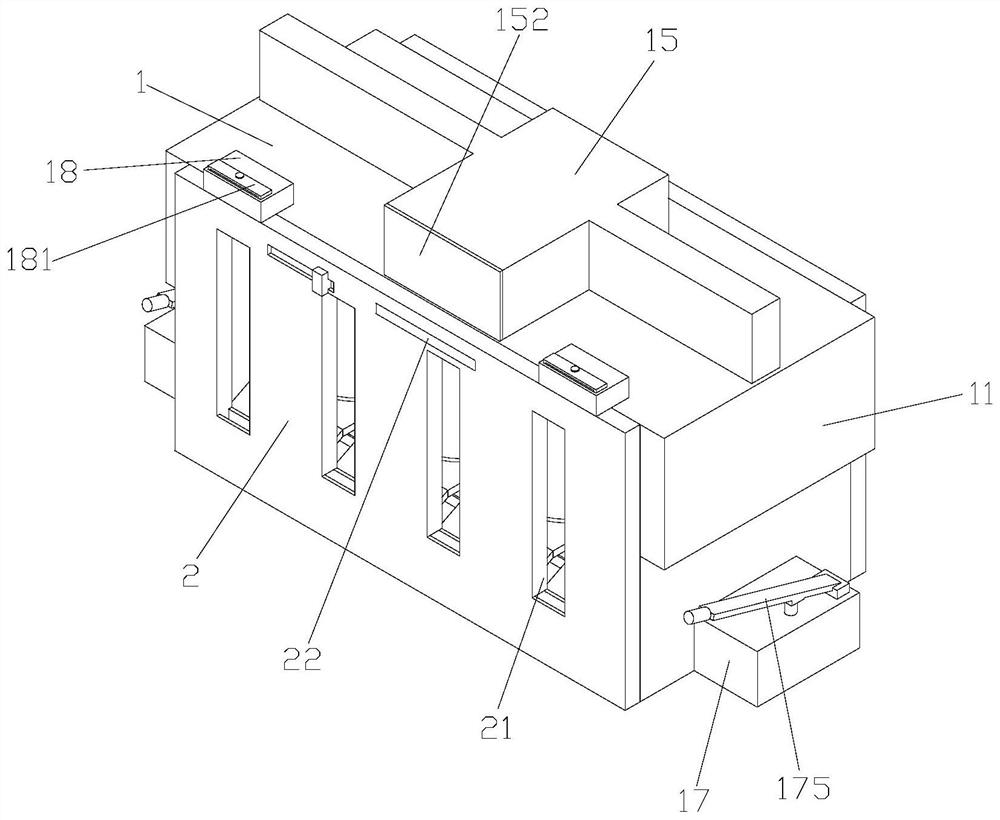

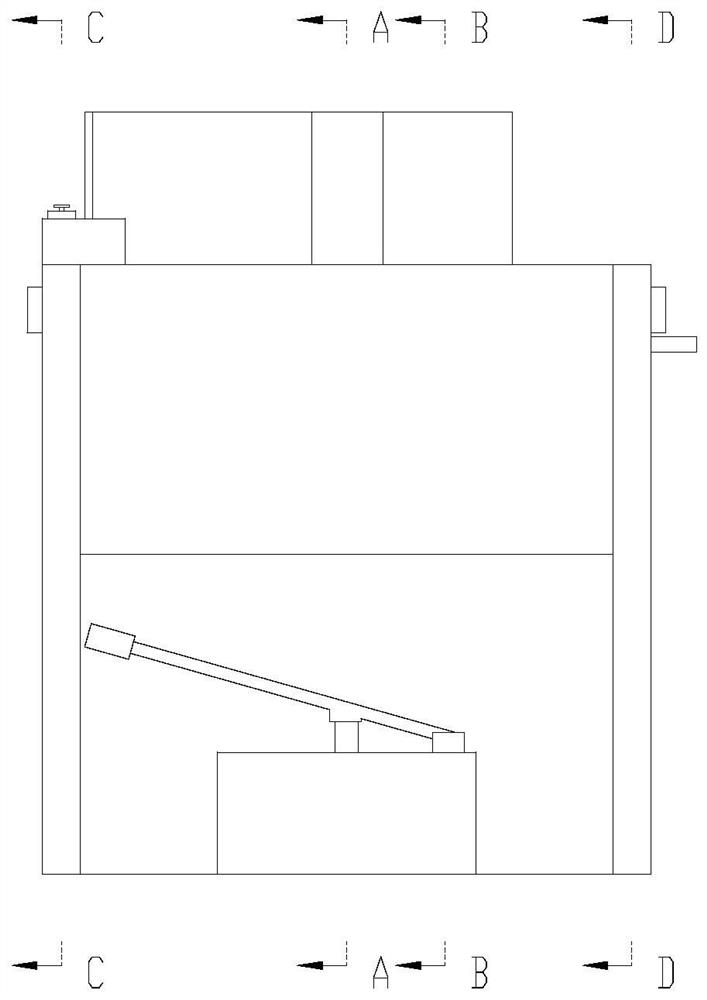

[0043] Such as Figure 1-26 As shown, a train storage battery online monitoring system includes a display controller, a TBMS controller and a monitoring device. Box board 3, the bottom of the first box board is hinged to the bottom surface of the battery box, the top of the battery box 1 is provided with a plurality of sensors, the sensors can monitor CO gas, smog, temperature, flame, etc., the first box board 2 A plurality of first through grooves 21 are provided, and a plurality of second through grooves are arranged on the second box plate 3, and first through grooves 21 matched with the first box plate 2 are provided on the first box plate 2. A baffle 23, the second box plate 3 is provided with a second baffle matching the second through groove, when a leak or fire occurs in the battery box 1, the first baffle 23 moves to the The first through slot 21, the second baffle moves to the second through slot; through the cooperation of the display controller, BMS controller and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com