Planetary roller screw pair contact point solving method

A planetary roller, screw pair technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problem of difficulty in determining whether the contact points meet the contact conditions, collinearity, and the inability to determine the minimum axial spacing point And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

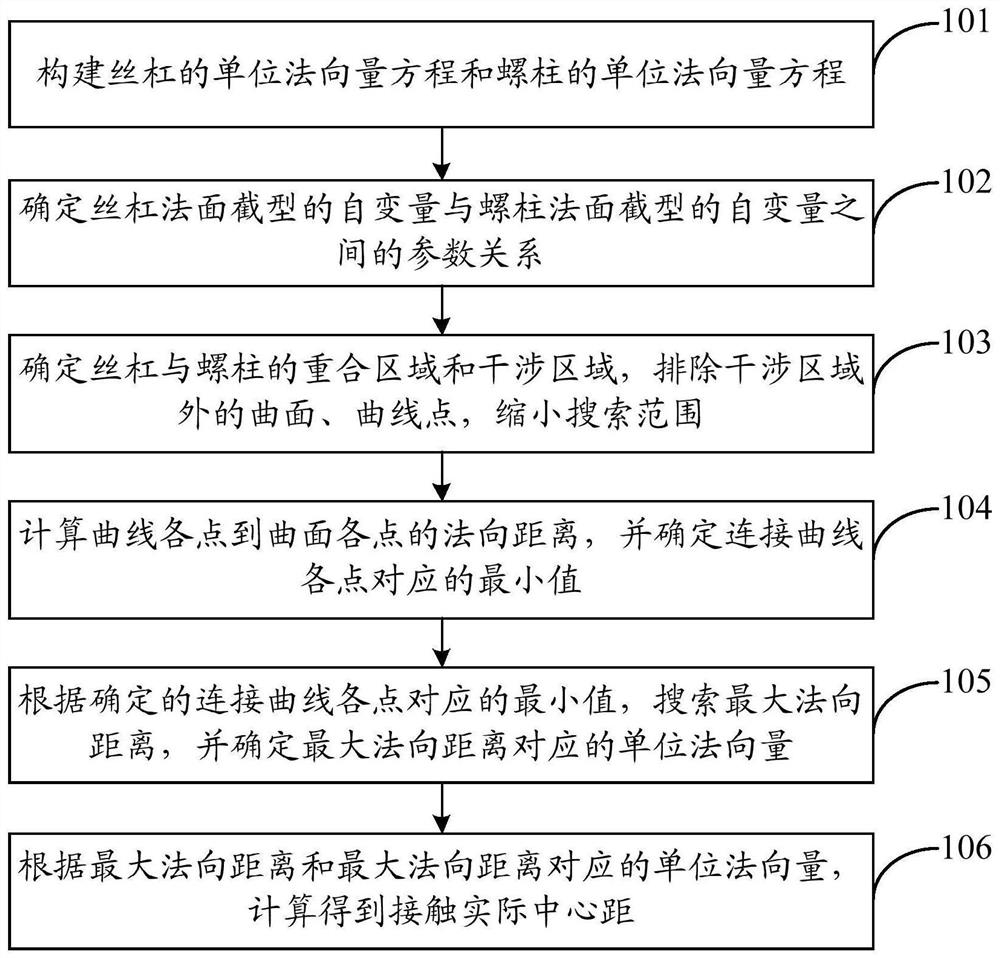

[0077] Such as figure 1 , in this embodiment, the method for solving the contact point of the planetary roller screw pair includes:

[0078] Step 101 is to construct the unit normal vector equation of the lead screw and the unit normal vector equation of the stud.

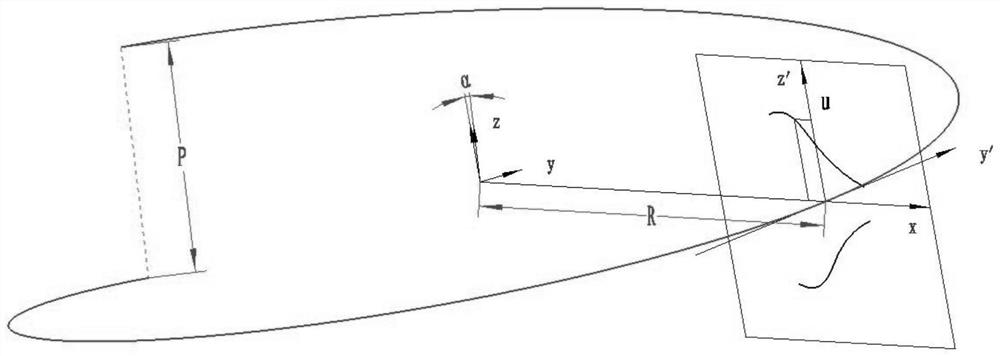

[0079] In this example, a helix Г is drawn in the coordinate system O-XYZ:

[0080]

[0081] Among them, R—radius of rotation, P—lead, v—angle of rotation, It is also called the rotation parameter P0.

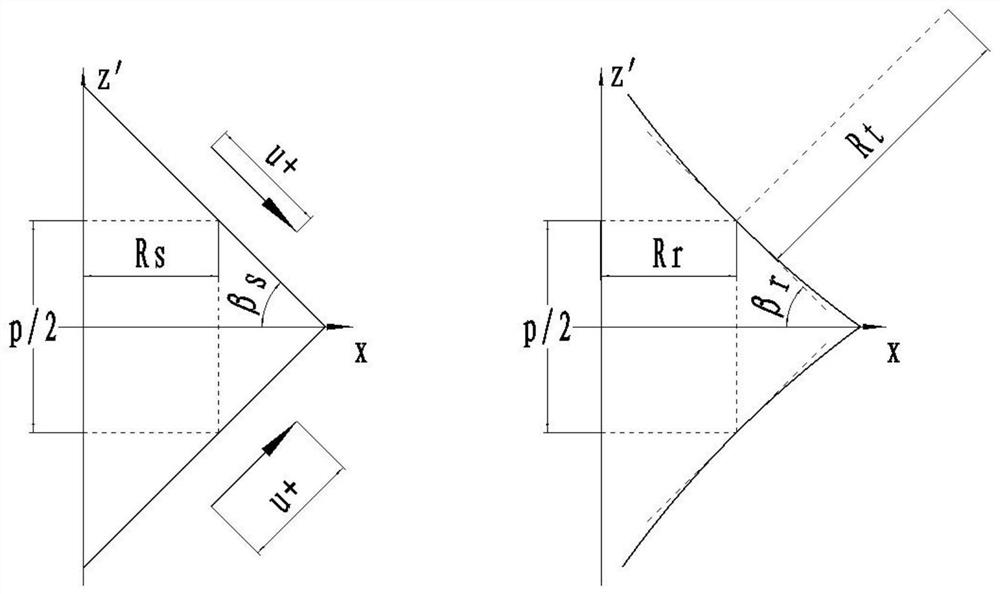

[0082] The section of the helicoid is made along the tangent direction at a certain point of the vertical helix, and the section is the normal section O'-X'Y'Z' of the helix, Y' is the tangent direction of the helix, and the angle between Z' and Z is Helix angle Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com