Gantry type five-axis linkage vertical lathe

A five-axis linkage, gantry-type technology, applied in the field of structural parts processing, can solve the problem that the vertical lathe cannot process the internal holes and planes of the workpiece, so as to avoid secondary clamping and improve the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

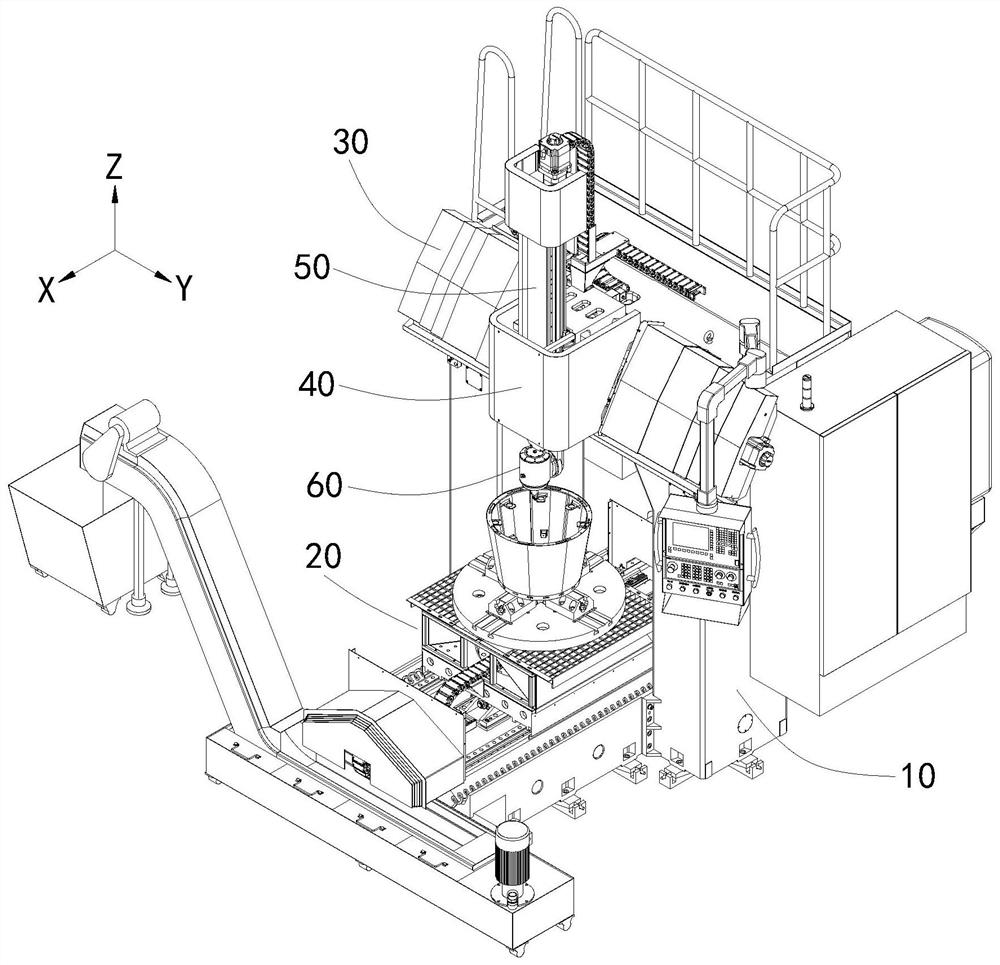

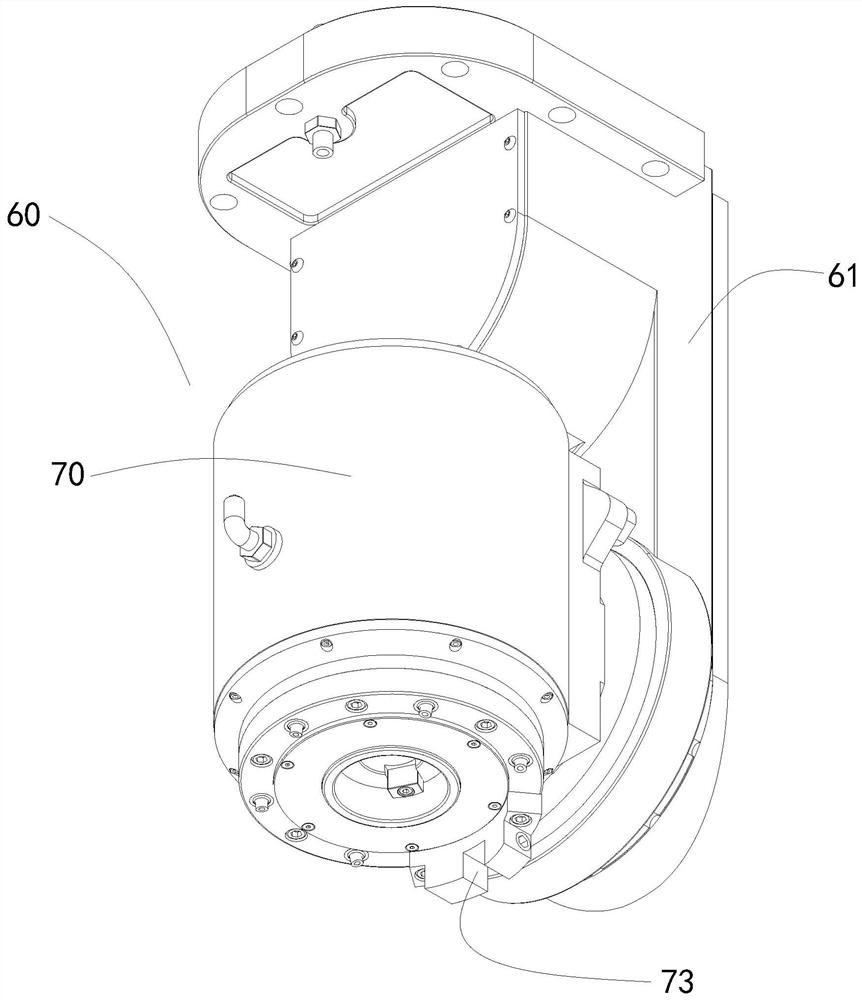

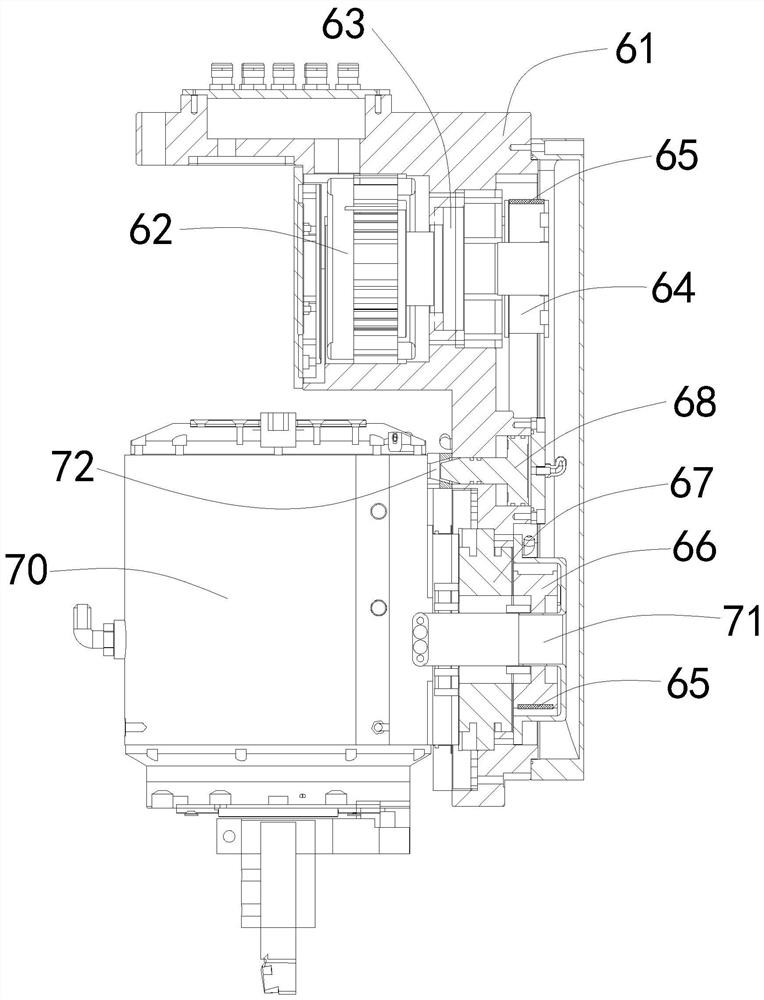

[0035]Such asFigure 1~3As shown, the present invention provides a gantry-type five-axis linkage vertical lathe, the vertical lathe includes: a bed column 10, a worktable 20, a beam 30, a carriage 40, a ram 50, and a pendulum spindle 60; The bed column 10 is fixed on the foundation, the beam 30 is installed on the bed column 10 to form a gantry frame, the workbench 20 is installed on the guide rail of the bed, and the screw drive mechanism drives along the X axis The carriage 40 is installed on the guide rail of the cross beam 30 and is driven by the screw drive mechanism to slide freely along the Y-axis direction; the ram 50 is installed on the carriage 40 and is driven by the screw drive mechanism It is pushed to slide freely along the Z axis; the single pendulum spindle 60 is mounted on the ram 50. The single pendulum spindle 60 includes an electric spindle 70 and a servo rotating mechanism. The electric spindle 70 passes through a horizontally arranged rotating shaft 71 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com