Novel paper binding machine

A binding machine and paper technology, applied in binding and other directions, can solve problems such as poor pressing, inconvenient maintenance, and difficult disassembly and assembly, and achieve the effects of simple structure, easy protection, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

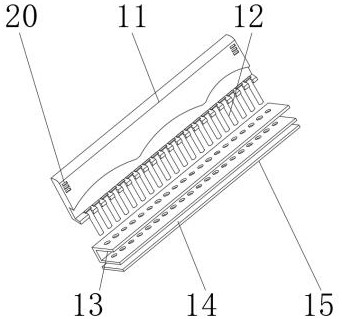

[0026] Embodiment one, such as figure 2 and 3 As shown, the position of the lower end of the arched pressing plate 11 is a combination of multiple groups of arched structures, and the interior is wavy. A positioning groove is provided between the T-shaped punching needle 12 and the positioning support 13, and the outer wall of the T-shaped punching needle 12 is positioned by positioning. The slot is movably connected to the inner side of the positioning support 13. The inside of the positioning support 13 is a hollow structure. A chute and a return spring are arranged between the arched pressing plate 11 and the fixed side plate 16. Both sides of the arched pressing plate 11 pass through the chute. 1. The return spring is movably connected to the inner side of the fixed side plate 16, which facilitates better paper stamping and binding operations, reduces pressure, makes the operation more convenient and practical, and can also facilitate and better position and increase the ...

Embodiment 2

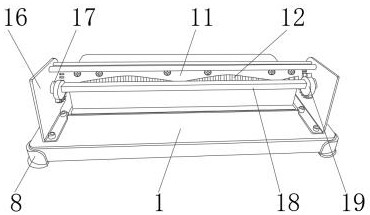

[0027] Embodiment two, such as Figure 4 As shown, the outer two ends of the fixed side plate 16 are provided with a dismounting block 7, between the fixed side plate 16 and the dismounting block 7, an adjusting frame 4 is arranged, and the inner side of the upper end of the adjusting frame 4 is provided with a remote lever 5, and the remote lever 5 Positioning pins 3 are arranged at both ends of the two sides, a bearing is arranged between the fixed side plate 16 and the rotating shaft 17, the inner wall of the fixed side plate 16 is movably connected with the outer wall of the rotating shaft 17 through the bearing, and between the rotating shaft 17 and the pressing gear 19 A fixed block is provided, and one end of the rotating shaft 17 is fixedly connected with the interior of the press-fitting gear 19 through the fixed block. A block is arranged between the adjusting frame 4 and the rotating shaft 17. The outer wall is fixedly connected, and the lower end of the adjustment ...

Embodiment 3

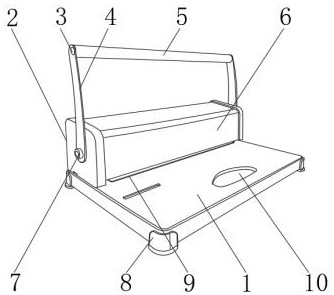

[0028] Embodiment three, such as figure 1 As shown, a positioning block is arranged between the side shell 2 and the fixed side plate 16, the outside of the fixed side plate 16 is detachably connected to the inside of the side shell 2 through the positioning block, and the side shell 2 and the main body shell 6 A connecting block is provided, and the inner side of the side shell 2 is fixedly connected with both sides of the main body shell 6 through the connecting block. The structure is simple, detachable and easy to repair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com